Device and method for converting cyanogen-containing organic waste liquid into nitrogen-doped carbon nanomaterial

A technology of organic waste liquid and nitrogen-doped carbon, applied in chemical instruments and methods, nano-carbon, inorganic chemistry, etc., can solve complex engineering problems and other problems, achieve temperature control problems, save power consumption, and solve gasification Effects of Energy Consumption Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

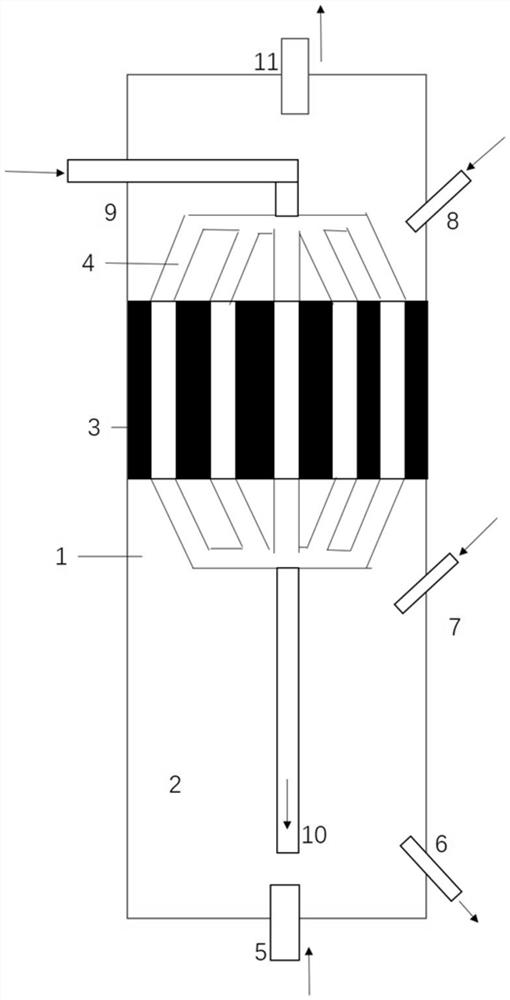

[0033] according to figure 1 In the assembled device, the height of the fixed bed section 3 is 1:5 of the height of the fluidized bed section 3 .

[0034]Fill catalyst (10% NiFe alloy (9% Fe-1% Ni)-42% aluminum oxide-48% magnesia) in fluidized bed section 2 through fluidized bed catalyst inlet 7, through fixed bed catalyst inlet 8 to fixed Bed section 3 is packed with catalyst (1% Ni-1% W-98% silica). The weight of the catalyst in the fixed bed section 3 is 1:5 of the catalyst weight in the fluidized bed section 2 . The auxiliary fluidized bed gas (Ar) is fed into the fluidized bed section 2 from the auxiliary fluidized bed gas inlet 5, and its mass flow rate is 5% of the cyanide-containing organic waste liquid, and the fluidized bed section 2 is heated to 500°C.

[0035] From the inlet cyanide-containing organic waste liquid inlet 9 of the vaporizer 4, pass into the cyanide-containing organic waste liquid (95% molecular weight is organic matter of 60-300, 5% water), passes ...

Embodiment 2

[0040] according to figure 1 In the assembled device, the height of the fixed bed section 3 is 1:4 of the height of the fluidized bed section 3 .

[0041] Load catalyst (1%CoMoW alloy (0.9%Co-0.05%Mo-0.05%W)-99% silicon oxide) in the fluidized bed section 2 through the fluidized bed catalyst inlet 7, and feed the fixed bed through the fixed bed catalyst inlet 8 Stage 3 is loaded with catalyst (10% Co-10% Mo-25% silica-55% alumina). The weight of the catalyst in the fixed bed section 3 is 2:1 of the catalyst weight in the fluidized bed section 2 . The auxiliary fluidized bed gas (Ar) is fed into the fluidized bed section 2 from the auxiliary fluidized bed gas inlet 5, and its mass flow rate is 1% of the cyanide-containing organic waste liquid, and the fluidized bed section 2 is heated to 800°C.

[0042] From the cyanogen-containing organic waste liquid inlet 9 of vaporizer 4, pass into cyanide-containing organic waste liquid (molecular weight is the organic matter of 80-300),...

Embodiment 3

[0047] according to figure 1 In the assembled device, the height of the fixed bed section 3 is 1:2 of the height of the fluidized bed section 3 .

[0048] Fill catalyst (30% NiCu alloy (10%Ni-20%Cu)-70% alumina) into fluidized bed section 2 through fluidized bed catalyst inlet 7, and fill fixed bed section 3 through fixed bed catalyst inlet 8 Catalyst (10% Co-5% Mo-45% Magnesia-40% Alumina). The weight of the catalyst in the fixed bed section 3 is 2:1 of the catalyst weight in the fluidized bed section 3 . Pass the auxiliary fluidized bed gas (Ar) from the fluidized bed auxiliary gas inlet 5 to the fluidized bed section 2), and its mass flow rate is 1% of the cyanide-containing organic waste liquid, and the fluidized bed section 2 is heated to 750°C .

[0049] From the cyanide-containing organic waste liquid inlet 9 of vaporizer 4, pass into cyanide-containing organic waste liquid (molecular weight is the organic matter of 26-350), pass through vaporizer downwards, carry ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com