Vegetable fat-based latex, preparation method and application thereof

A vegetable oil-based latex technology, which is applied in the field of preparation and vegetable oil-based latex, can solve the problems of the use, preparation and performance research of pure vegetable oil latex.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of tallow tree oil epoxy latex: 100 parts by weight of tallow tree oil epoxy monomer, 200 parts of deionized water, 5 parts of emulsifier, 5 parts of emulsifier, and 0.5 part of PH regulator are stirred and ultrasonically alternated for about 1 hour Mix evenly to form a pre-emulsion, take about 20% by weight of the pre-emulsion in a three-necked flask as a primer, heat to 60°C, add 0.3 parts by weight of an initiator to react for 30 minutes, and start to drop the remaining pre-emulsion at a rate of about 3 seconds / drop. After the remaining pre-emulsion is added dropwise, add 0.3 part of initiator and continue the reaction for 4 hours, then raise the temperature to 80°C and keep it warm for 30 minutes, and finally cool down to room temperature and pass through a nylon filter to obtain tallow catalpa oil epoxy emulsion.

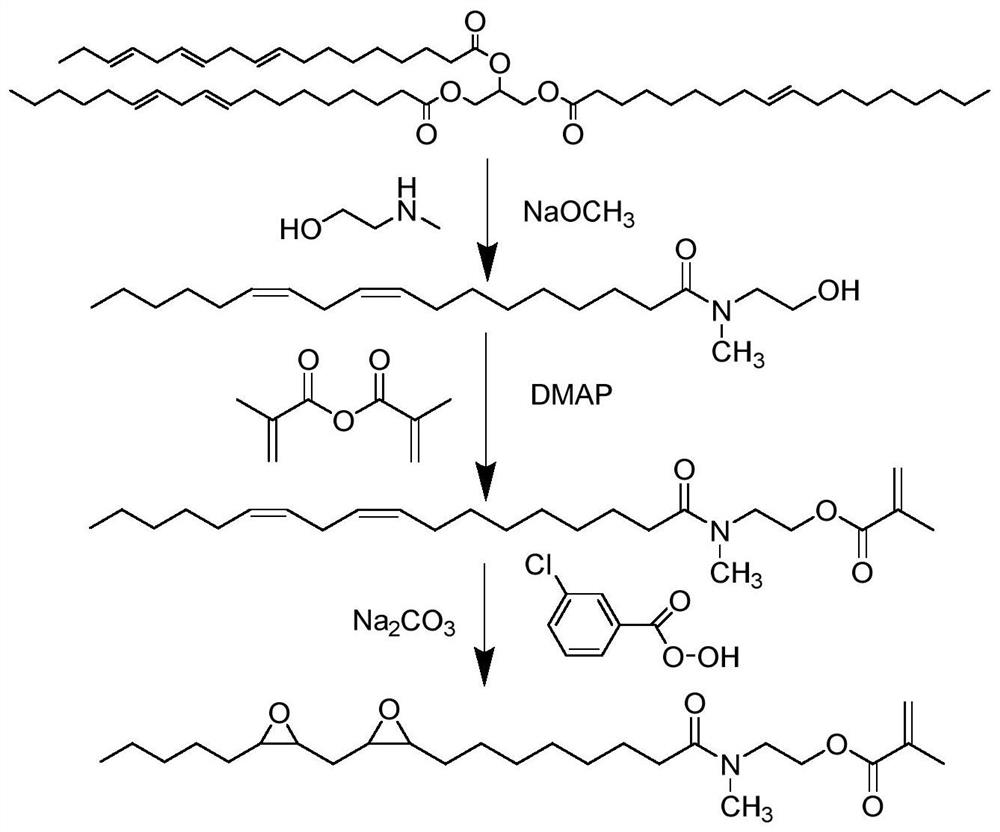

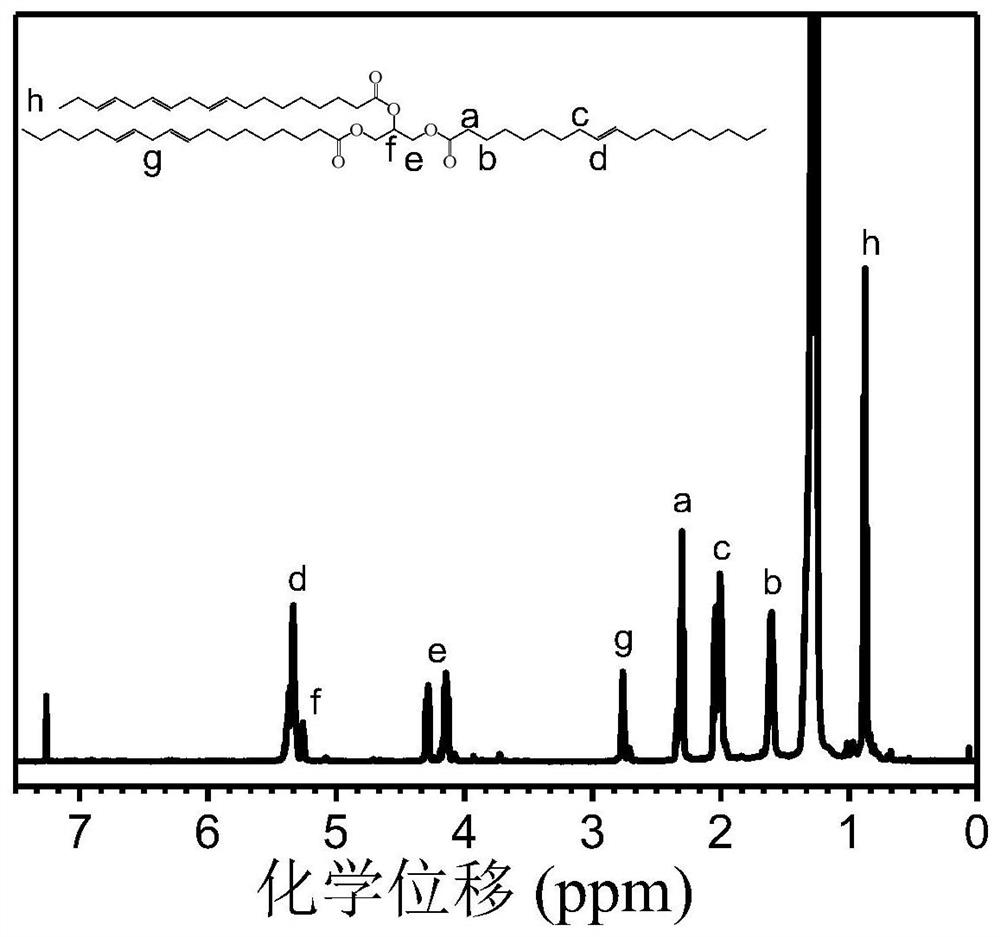

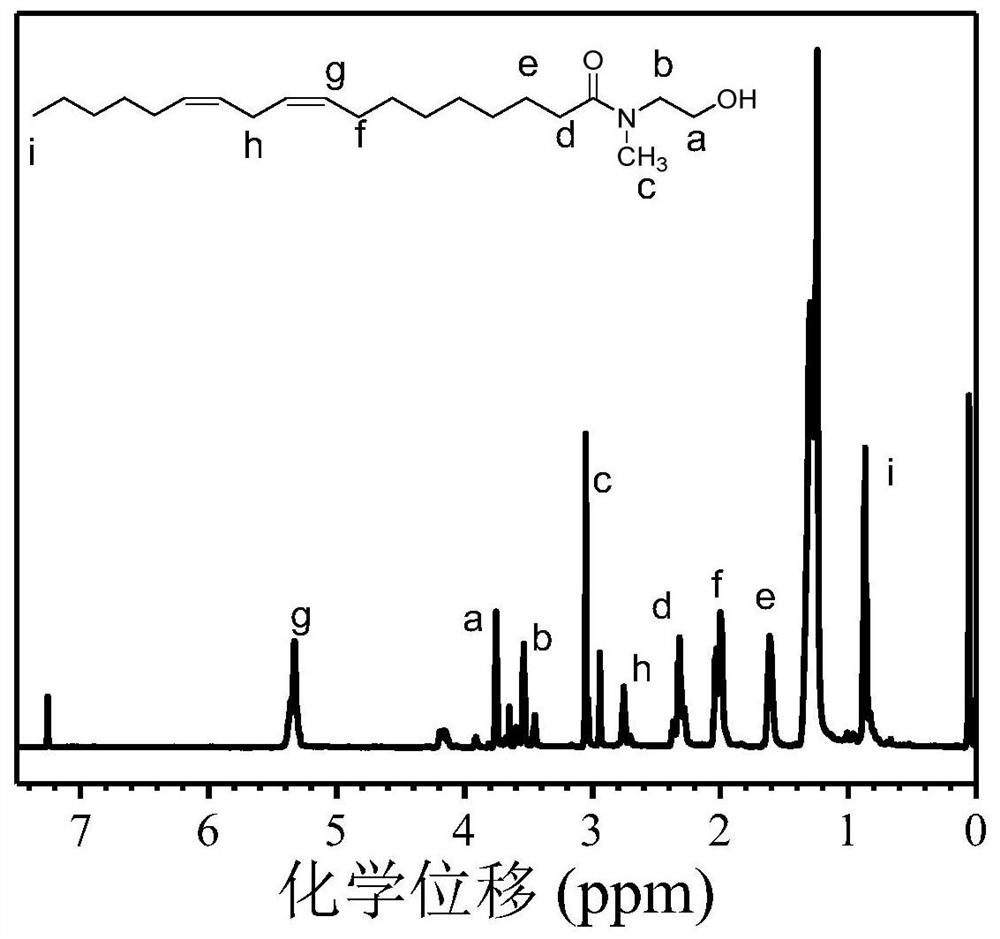

[0038] Such as figure 1 Shown, wherein vegetable oil base fatty acid epoxy monomer: the preparation process of tallow tree oil epoxy monom...

Embodiment 2

[0052] Preparation of palm oil epoxy latex: 200 parts by weight of palm oil epoxy monomer, 400 parts of deionized water, 10 parts of emulsifier, 10 parts of co-emulsion agent, and 1 part of pH regulator are uniformly mixed by stirring and ultrasonic to form a pre-emulsion . Get about 20% by weight of the pre-emulsion in a three-necked flask, heat it to 60 ° C, add 0.6 parts by weight of the initiator to react for 30 minutes, and start to drop the remaining pre-emulsion at a rate of about 5 seconds / drop. After the remaining pre-emulsion was added dropwise, 0.6 parts by weight of initiator was added to continue the reaction for 5 hours, the temperature was raised to 80° C. for 30 minutes, and the temperature was finally cooled to room temperature and passed through a nylon filter to obtain palm oil epoxy latex.

[0053] Wherein vegetable oil-based fatty acid epoxy monomer: the preparation process of palm oil epoxy monomer is the same as embodiment one.

[0054] The preparation ...

Embodiment 3

[0056] The preparation of high oleic rapeseed oil epoxy latex: 150 parts by weight of high oleic rapeseed oil epoxy monomer, 300 parts of deionized water, 7.5 parts of emulsifier, 7.5 parts of co-emulsion agent, 0.75 part of pH regulator through Stirring and ultrasonic mixing uniformly form a pre-emulsion. Take about 20% by weight of the pre-emulsion in a three-necked flask, heat it to 60° C., add 0.45 parts by weight of an initiator to react for 30 minutes, and start to drop the remaining pre-emulsion at a rate of about 4 seconds / drop. After the remaining pre-emulsion is added dropwise, add 0.45 parts of initiator to continue the reaction for 3 hours, heat up to 80°C and keep warm for 30 minutes, and finally cool down to room temperature and pass through a nylon filter to obtain high oleic rapeseed oil epoxy emulsion.

[0057] Wherein the vegetable oil-based fatty acid epoxy monomer: the preparation process of the high oleic rapeseed oil epoxy monomer is the same as in Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average relative molecular weight | aaaaa | aaaaa |

| Relative molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com