Cellulose nanofibril-PBAT composite film as well as preparation method and application thereof

A nanofibril and composite film technology, applied in the field of bio-based degradable films, can solve the problems that cellulose cannot form interwoven network connections, cannot retain nanocellulose amorphous regions, and reduce nanocellulose yield, etc. Good waterproof performance, high elongation at break, rich in hydroxyl groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A kind of cellulose nano fibril-PBAT composite film, its preparation method comprises the following steps:

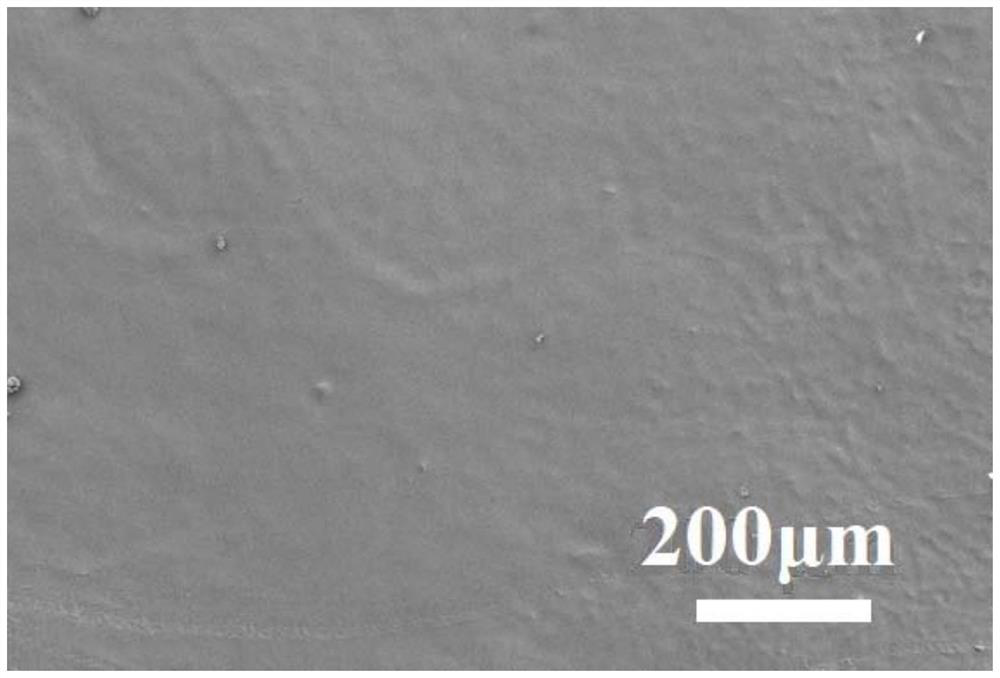

[0055] 1) Add 50 g of hardwood pulp into water, soak for 24 hours, prepare a cellulose suspension with a mass fraction of 1%, and then transfer it to a superfine particle pulverizer (Japan Zengxing Sangyo Co., Ltd., model: MKCA6-2J) In the process, adjust the rotating speed of the ultrafine particle pulverizer to 2000r / min, the gap is 5 μm, and circulate the pulverization process 20 times, centrifuge, and the solid product obtained is redispersed with water to obtain cellulose nanofibrils (length 200nm~ 1500nm, diameter 1nm~150nm) dispersion liquid;

[0056] 2) Add 8g of nano-soil (particle size 200nm to 350nm) dispersion with a mass fraction of 5% into 300g of cellulose nanofibril dispersion with a mass fraction of 1%, and magnetically stir for 1 hour to obtain cellulose nanofibrils- Nano-soil mixture;

[0057]3) Pour the cellulose nanofibril-nanosoil mixture ...

Embodiment 2

[0062] A kind of cellulose nano fibril-PBAT composite film, its preparation method comprises the following steps:

[0063] 1) Add 100 g dry weight softwood pulp into water, soak for 36 hours, prepare a cellulose suspension with a mass fraction of 3%, and then transfer it to an ultrafine particle pulverizer (Japan Zengxing Sangyo Co., Ltd., model: MKCA6-2J) In the process, adjust the rotating speed of the ultrafine particle pulverizer to 4000r / min, the gap is 20 μm, and circulate the crushing process 20 times, centrifuge, and the solid product obtained is redispersed with water to obtain cellulose nanofibrils with a mass fraction of 3% (length 200nm~ 2000nm, diameter 1nm ~ 300nm) dispersion liquid;

[0064] 2) Add 10.53g of 5% nano-soil (particle size 200nm to 500nm) dispersion into 320g of 3% cellulose nanofibril dispersion, and stir magnetically for 1 hour to obtain cellulose nanofibrils - nano-soil mixture;

[0065] 3) Pour the cellulose nanofibril-nanosoil mixture into a ...

Embodiment 3

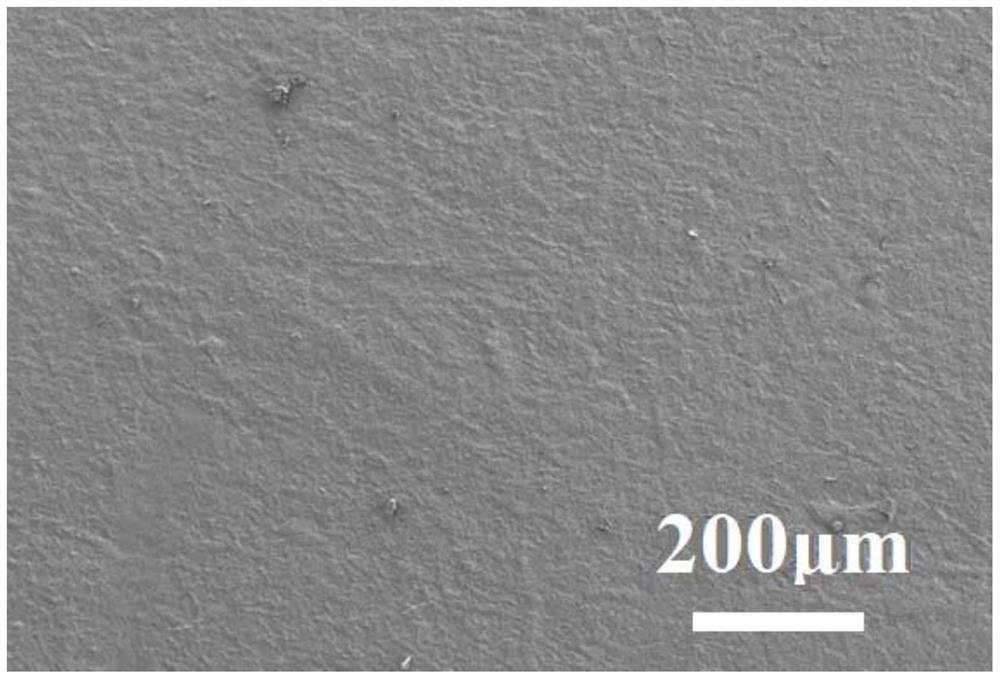

[0070] A kind of cellulose nano fibril-PBAT composite film, its preparation method comprises the following steps:

[0071] 1) Add cotton pulp with a dry weight of 50 g into water, soak for 48 hours, prepare a cellulose suspension with a mass fraction of 5%, and then transfer it to a superfine particle pulverizer (Japan Zengxing Sangyo Co., Ltd., model: MKCA6-2J) , adjust the rotating speed of the superfine particle grinder to 2500r / min, the gap is 10 μm, and the circulation pulverization process is 15 times, centrifuged, and the solid product obtained is redispersed with water to obtain cellulose nanofibrils (length 200nm~4000nm) with a mass fraction of 5%. , diameter 1nm ~ 200nm) dispersion;

[0072] 2) Add 6.5g of 5% nano-soil (particle size 250nm to 500nm) dispersion into 100g of 5% cellulose nanofibril dispersion, and magnetically stir for 1 hour to obtain cellulose nanofibrils - nano-soil mixture;

[0073] 3) Pour the cellulose nanofibril-nanosoil mixture into a film ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com