Preparation process of syrup for snowflake crisps and prepared syrup for snowflake crisps

A preparation process and syrup technology, applied in the field of syrup for snowflakes, can solve the problems of difficult stirring and high viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A preparation process for snowflake crisp syrup, comprising the steps of:

[0060] Slurry opening: Mix 1kg of tapioca starch with 1kg of water to prepare a starch slurry with a concentration of 16.5Be and a pH of 5.6; then add 0.05mL of α-amylase and stir evenly;

[0061] Steam injection, flash evaporation and laminar flow liquefaction: the starch slurry added with α-amylase is steam injected at a temperature of 106°C for 15 minutes, then flashed at a temperature of 95°C for 10 minutes, and then heated at a temperature of 85°C. Under the condition of laminar flow liquefaction for 4 hours, the temperature was finally lowered to 55°C to obtain liquefied slurry;

[0062] Saccharification: Mix 0.15mL of β-amylase and 0.15mL of pullulanase, then add to the liquefied slurry, saccharify at a temperature of 55°C for 24h, then add 0.02mL of maltogenic α-amylase, and continue saccharifying for 22h , to prepare saccharified syrup;

[0063] Filtration: Add 0.27kg of perlite to ea...

Embodiment 2

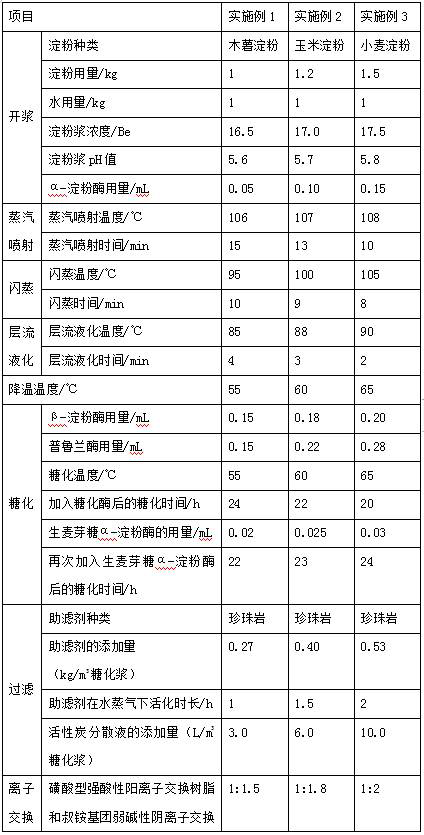

[0067] The difference between this embodiment and the above-mentioned embodiment 1 lies in that the parameter conditions of the preparation process are different from those of the embodiment 1, see Table 2 for details.

Embodiment 3

[0069] The difference between this embodiment and the above-mentioned embodiment 1 lies in that the parameter conditions of the preparation process are different from those of the embodiment 1, see Table 2 for details.

[0070] The material difference and process parameter difference of above-mentioned embodiment 1-3 are referred to following table 2;

[0071] Table 2 Material type, material consumption and technological condition difference table of embodiment 1-3

[0072]

[0073] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com