Sacrificial anode service performance monitoring and failure risk early warning system in ocean back-silting environment

A sacrificial anode and risk early warning technology, applied in the field of cathodic protection, can solve the problems of heavy workload, failure risk early warning, time-consuming and labor-intensive problems, and achieve the effect of guaranteed effect and life, wide application range, and comprehensive monitoring parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

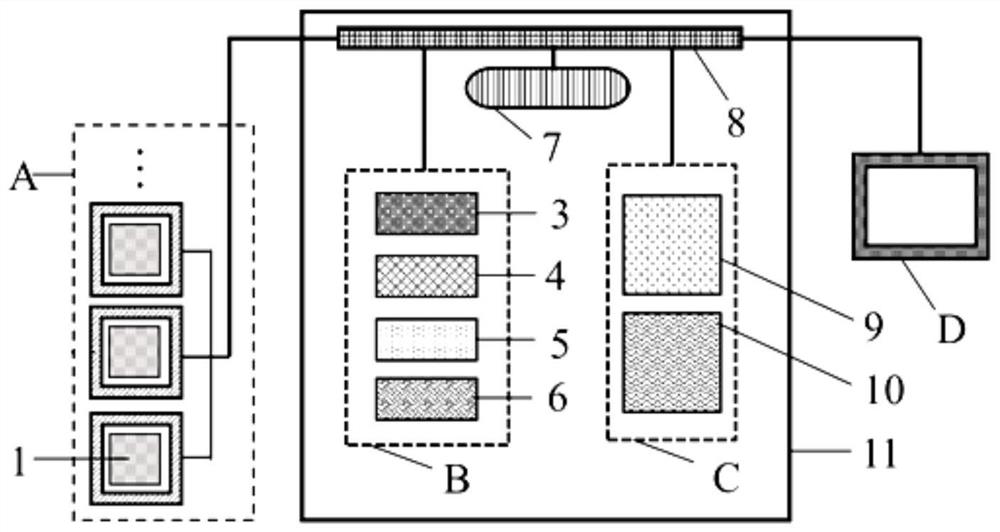

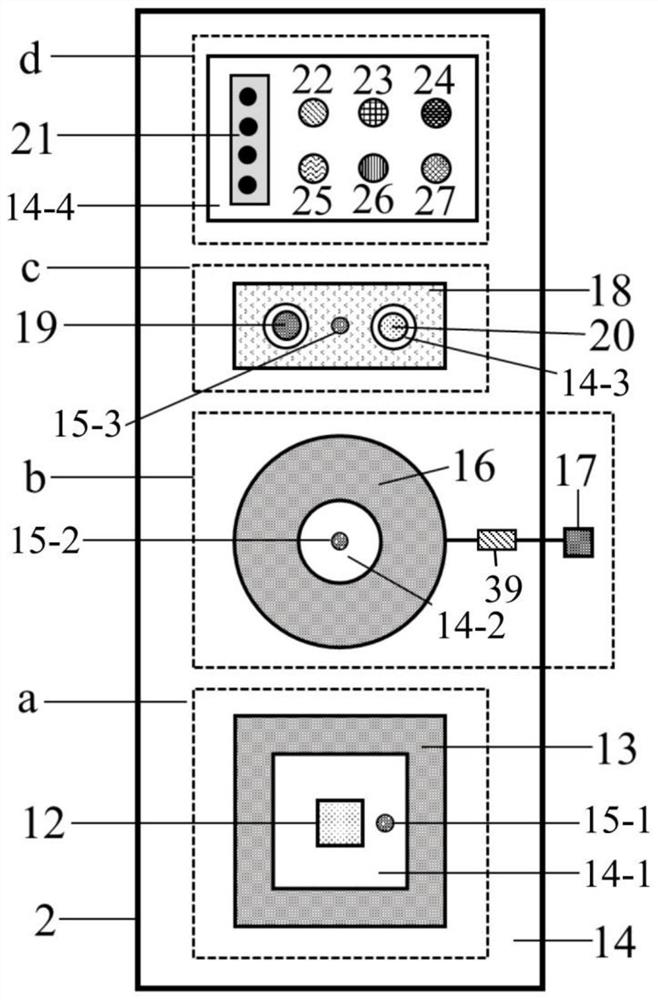

[0036] refer to figure 1 , is a schematic diagram of a sacrificial anode service performance monitoring and failure risk early warning system in a marine back-silting environment, which includes a sensor subsystem A, a data acquisition subsystem B, a data storage and transmission subsystem C, and a monitoring center D.

[0037] Sensor subsystem A includes single or multiple sensor groups 1, data acquisition subsystem B includes current acquisition module 3, voltage acquisition module 4, electrochemical test module 5, environmental parameter acquisition module 6, data storage and transmission subsystem C includes data storage Module 9 and communication module 10; through the wiring module 8, the sensor subsystem A is connected to the data acquisition subsystem B, the data acquisition subsystem B is connected to the data storage transmission subsystem C, and the power supply module 7 is connected to the data acquisition module B and the data storage transmission sub-system Syste...

Embodiment 2

[0056] Implementation method of sacrificial anode service performance monitoring and failure risk warning system in marine back-silting environment:

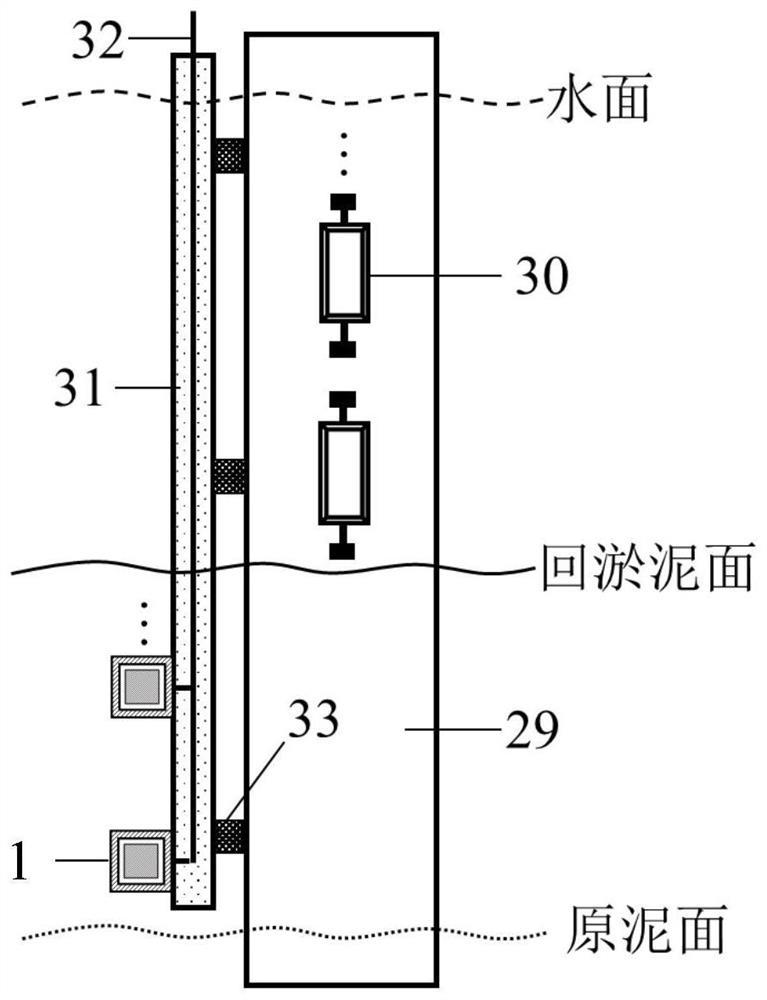

[0057] (1) Assemble and fix the sensor group 1 and the wire protection tube 31 with clamps, lay the wire 32 in the wire protection tube 31 for wiring, and do a good job of sealing protection;

[0058] (2) The combination of the assembled sensor group and the wire protection tube 31 is welded and fixed on the protected steel structure 29 through the welding leg 33;

[0059] (3) The wire 32 of the sensor subsystem A is connected with each module of the data acquisition subsystem B through the wiring module 8;

[0060] (4) Data acquisition subsystem B is connected with each module of data storage transmission subsystem C;

[0061] (5) Implement sacrificial anode service performance monitoring and failure risk warning through the whole system. The data acquisition subsystem regularly sends acquisition instructions to the sensor su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com