Composite air filter cotton processing equipment and processing technology thereof

An air filtration and composite technology, which is used in metal processing, textile and paper making, thin material processing, etc., can solve the problems of inconvenient adjustment of cutting width and reduction of air cotton production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

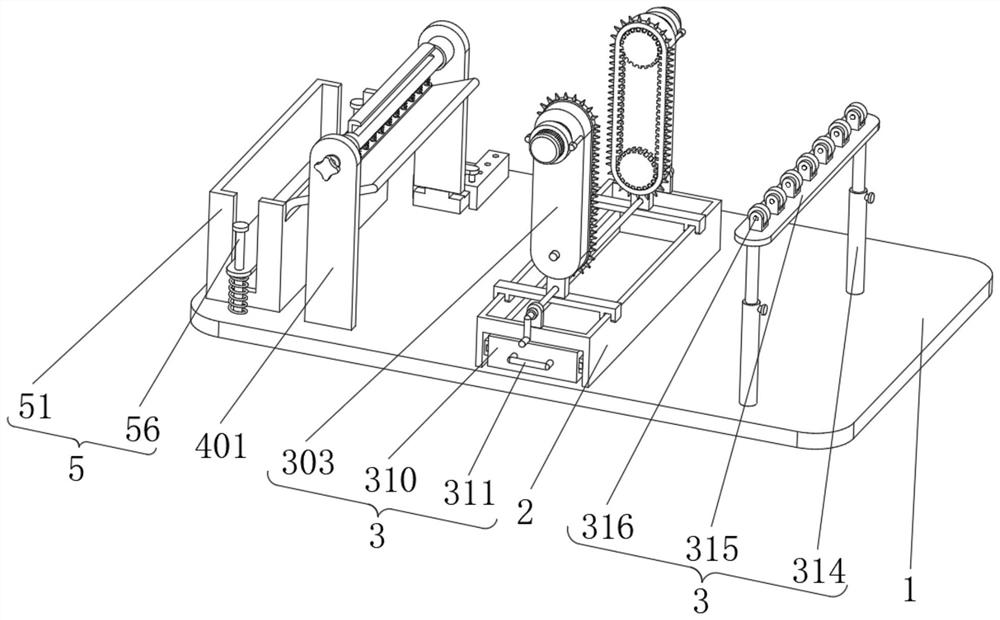

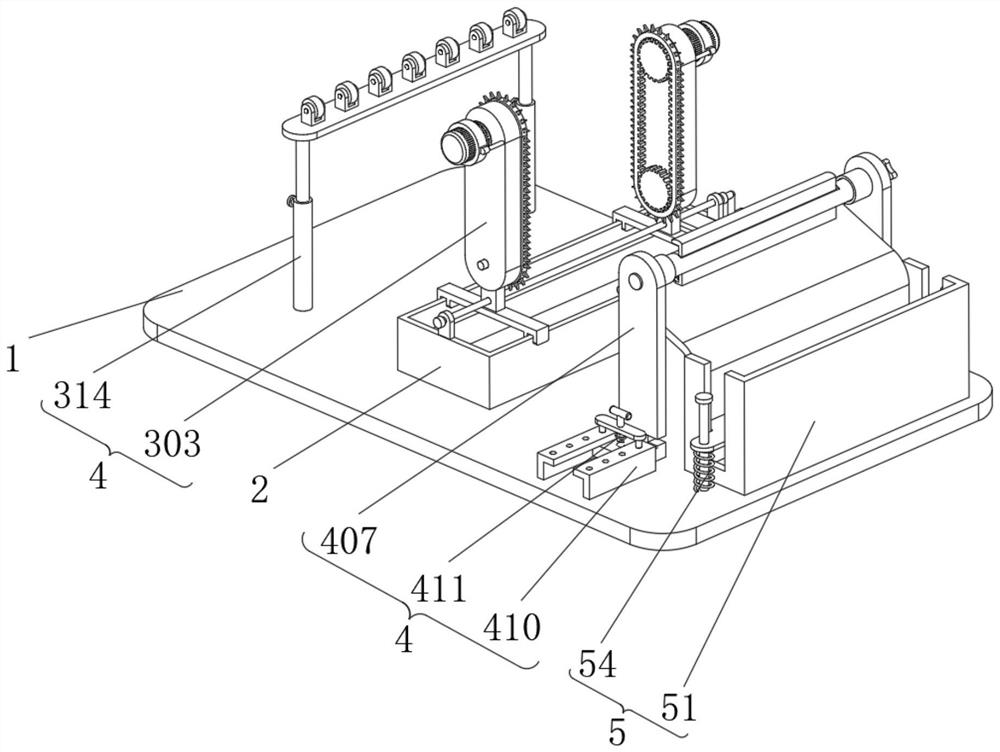

[0031] Example 1, such as Figure 1-8 As shown, the present invention provides a composite air filter cotton processing device, comprising a backing plate 1 and a cutting device 3, a support frame 2 is fixedly installed on the upper surface of the backing plate 1, and an end of the support frame 2 away from the backing plate 1 is provided with Cutting device 3.

[0032] Let's talk about the specific settings and effects of its cutting device 3, winding device 4 and storage device 5 in detail below.

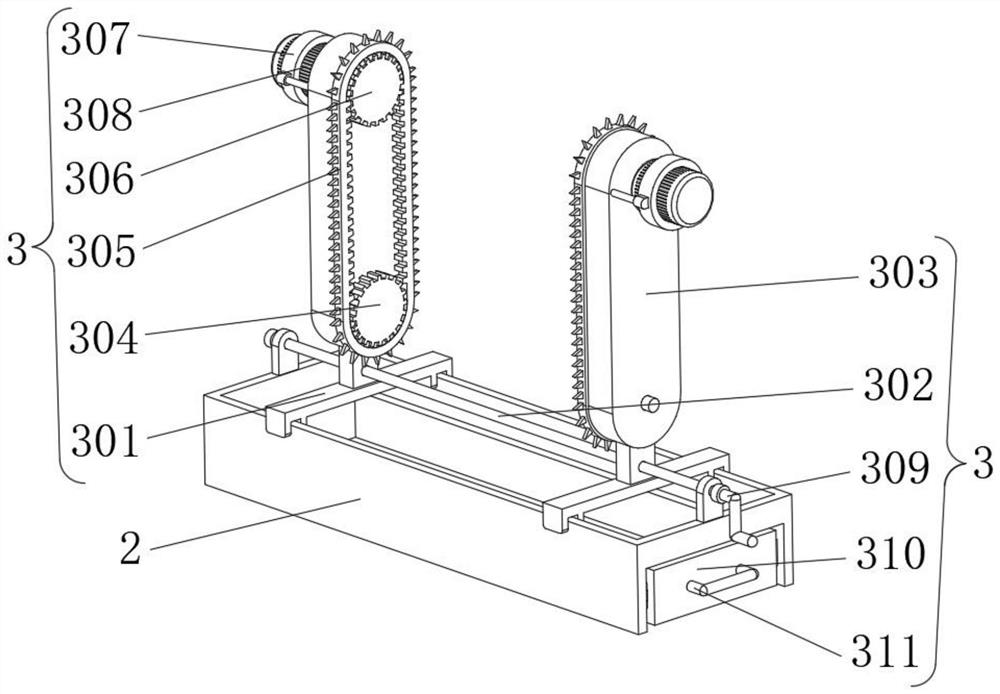

[0033] Such as image 3 with Figure 4 As shown, the cutting device 3 includes two slide plates 301, and the two slide plates 301 are evenly slidably connected to the upper end of the support frame 2, and the end of the support frame 2 away from the backing plate 1 is rotatably connected to a drive rod 302, and the two ends of the drive rod 302 are round The arc surface is provided with opposite threads, and the arc surface of the drive rod 302 is threadedly connected with two ...

Embodiment 2

[0039] Embodiment 2, on the basis of Embodiment 1, the backing plate 1 is provided with a storage device 5 near the side of the support frame 2, the storage device 5 includes a storage box 51, the lower surface of the storage box 51 is fixedly connected with the backing plate 1, and stores The surface of the box 51 is evenly provided with two sliding holes 52, the inner wall of the sliding hole 52 is slidably connected with a buffer plate 53, the surface of the buffer plate 53 is slidably connected with the inner wall of the storage box 51, and the side of the buffer plate 53 close to the backing plate 1 is uniform Two third springs 54 are fixedly connected, and one end of the third spring 54 away from the buffer plate 53 is fixedly connected with the backing plate 1, and the end of the storage box 51 away from the backing plate 1 is fixedly connected with a slant plate 55, and the slant plate 55 is located on the rotating rod 403 Directly below, the surface of the buffer plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com