Reinforcing method of marine concrete

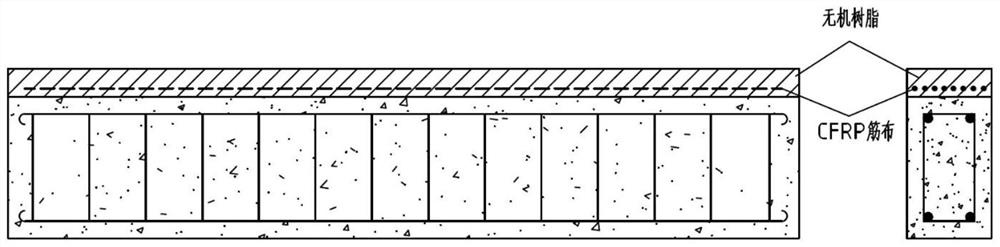

A marine concrete and mixture technology, which is applied in the field of reinforced concrete, can solve the problems of time-consuming and labor-intensive construction, shorten the construction time of low-temperature or humid marine concrete, etc., achieve the effect of not being easy to ultraviolet radiation, and solve the problem of long setting time and short setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The embodiment of the present application provides a damaged reinforced concrete member under simulated marine environment, and the manufacturing method includes the following steps:

[0050] S1, make reinforced concrete beam member (hereinafter referred to as RC member), the longitudinal tensile reinforcement of RC member is connected with electric wire;

[0051] S2. Half-immerse the RC member in step S1 into the electrolyte solution, connect the wire to the positive electrode of the power supply, and connect the negative electrode of the power supply to the cathode in the electrolyte solution, artificially accelerate the electrochemical corrosion of the RC member to obtain a damaged RC member with cracks formed.

[0052] Wherein, the above-mentioned electrolytic solution is configured with a mass fraction of 99% industrial NaCl solid to form a NaCl solution with a mass concentration of 5% as the electrolytic solution, and the electrolytic solution is contained in a cor...

Embodiment 2

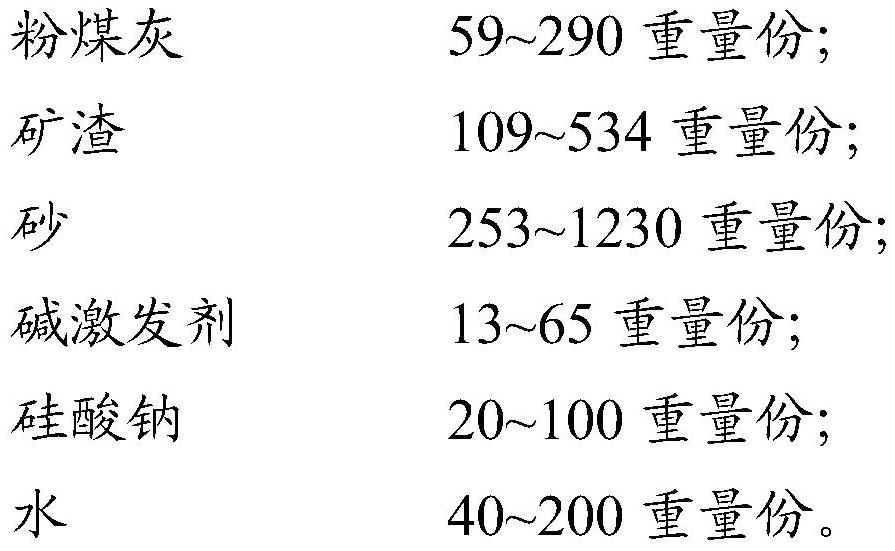

[0059] The embodiment of the present application provides an inorganic resin, including the following methods:

[0060] Prepare according to the steps of the following recipe:

[0061] 1. Add fly ash, slag, sand and sodium carbonate solid into the mortar mixer, mix and stir for 165s to obtain the mixture;

[0062] 2. Add the following 85% water into the mixture and stir for 45s;

[0063] 3. Add the remaining 15% of water and sodium silicate into the above mixture, and stir for 45 seconds to obtain an inorganic resin.

[0064]

Embodiment 3

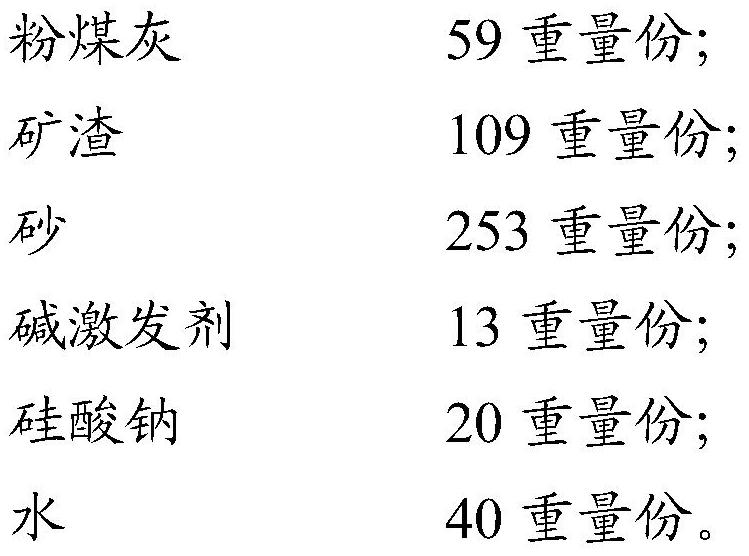

[0066] The embodiment of the present application provides an inorganic resin, including the following methods:

[0067] Prepare according to the steps of the following recipe:

[0068] 1. Add fly ash, slag, sand and sodium carbonate solid into the mortar mixer, mix and stir for 165s to obtain the mixture;

[0069] 2. Add the following 85% water into the mixture and stir for 45s;

[0070] 3. Add the remaining 15% of water and sodium silicate into the above mixture, and stir for 45 seconds to obtain an inorganic resin.

[0071]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com