Preparation method of high-purity aluminum metallographic specimen

A metallographic sample, high-purity technology, applied in the field of preparation of high-purity aluminum metallographic samples, can solve problems such as difficult to obtain good metallographic samples, and achieve clear metallographic structure and experimental reproducibility high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

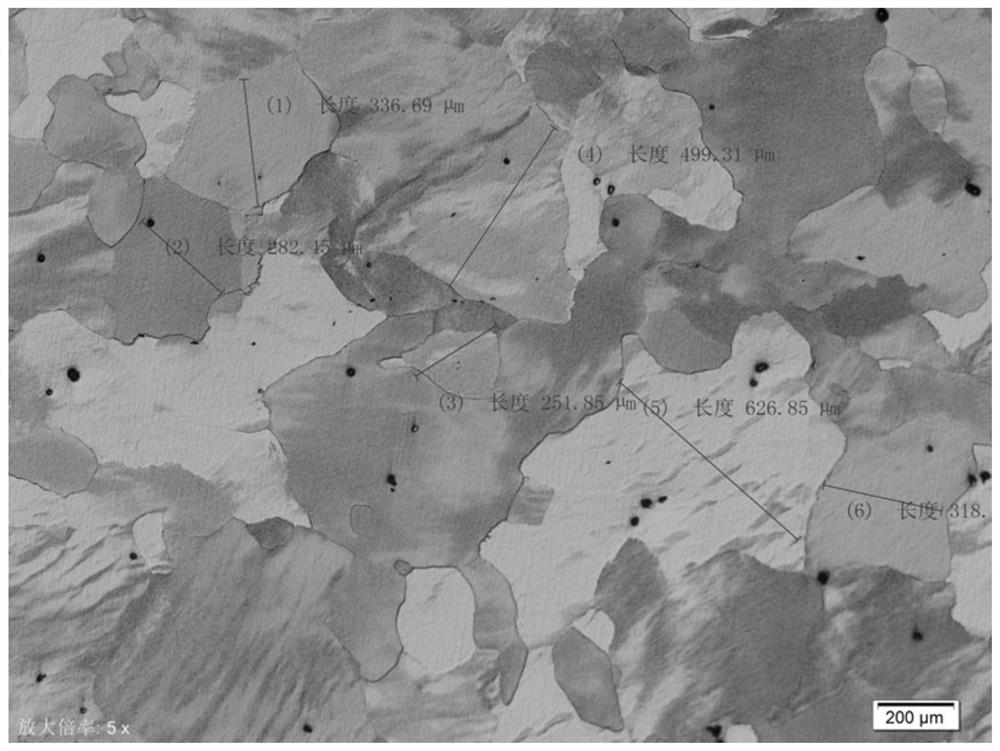

Embodiment 1

[0037] The preparation method of the high-purity aluminum metallographic sample of the present embodiment comprises the steps:

[0038] (1) Sampling

[0039] Use wire cutting equipment to cut 15mm*15mm*15mm high-purity aluminum as a sample, and the surface that needs to be metallographic is required to be flat and have no obvious concave-convex shape;

[0040] (2) mark

[0041] Mark the end face (C) and surface (S) that need to observe the metallographic phase in the sample as the grinding surface of the sample;

[0042] (3) Grinding

[0043] Grind the grinding surface of the sample on the grinding disc of the polishing machine, press the grinding surface of the sample on the 320# water-based sandpaper in turn, move in the radial direction and rotate in the opposite direction to the rotation direction of the grinding disc, so that the coarse grinding marks disappear completely, and Consistent fine grinding marks;

[0044] (4) Coarse throwing

[0045] Rotate the sample obt...

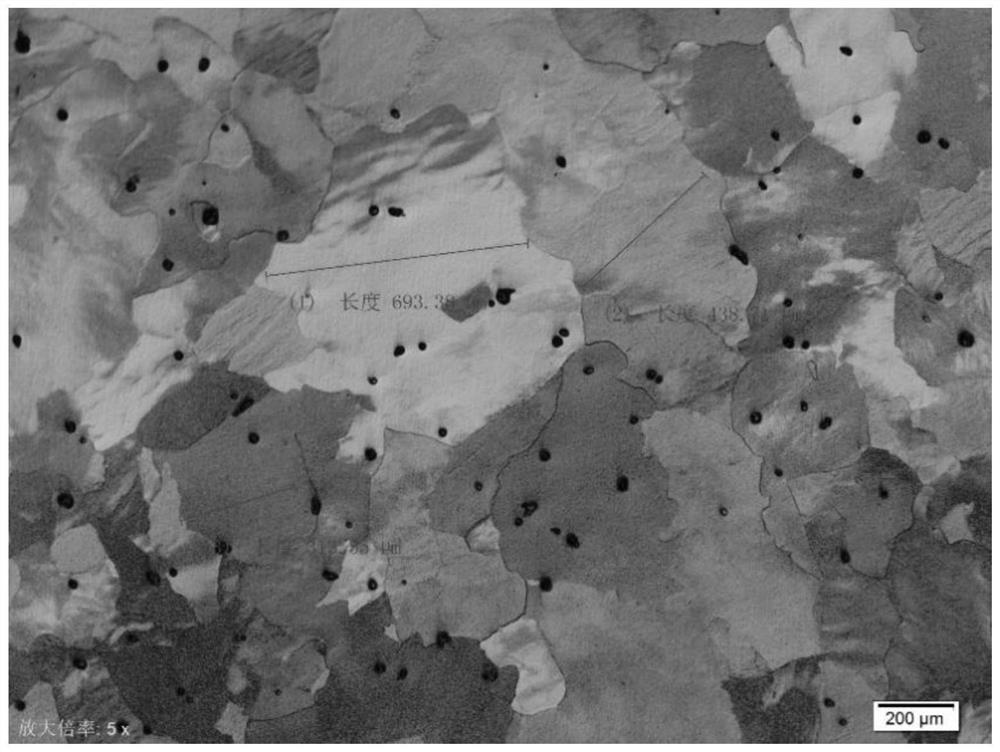

Embodiment 2

[0061] The preparation method of the high-purity aluminum metallographic sample of the present embodiment comprises the steps:

[0062] (1) Sampling

[0063] Use wire cutting equipment to cut 10mm*15mm*13mm high-purity aluminum as a sample, and the surface that needs to be metallographic is required to be flat and have no obvious concave-convex shape;

[0064] (2) mark

[0065] Mark the end face (C) and surface (S) that need to observe the metallographic phase in the sample as the grinding surface of the sample;

[0066] (3) Grinding

[0067] Grind the grinding surface of the sample on the grinding disc of the polishing machine, press the grinding surface of the sample on the 320# water-based sandpaper in turn, move in the radial direction and rotate in the opposite direction to the rotation direction of the grinding disc, so that the coarse grinding marks disappear completely, and Consistent fine grinding marks;

[0068] (4) Coarse throwing

[0069] Rotate the sample obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com