Preparation method of carbon-loaded nano-palladium catalyst for direct methanol fuel cell

A methanol fuel cell and nano-palladium technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of decreased resistance to methanol poisoning, high price, and difficulty in large-scale commercial application of direct methanol fuel cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

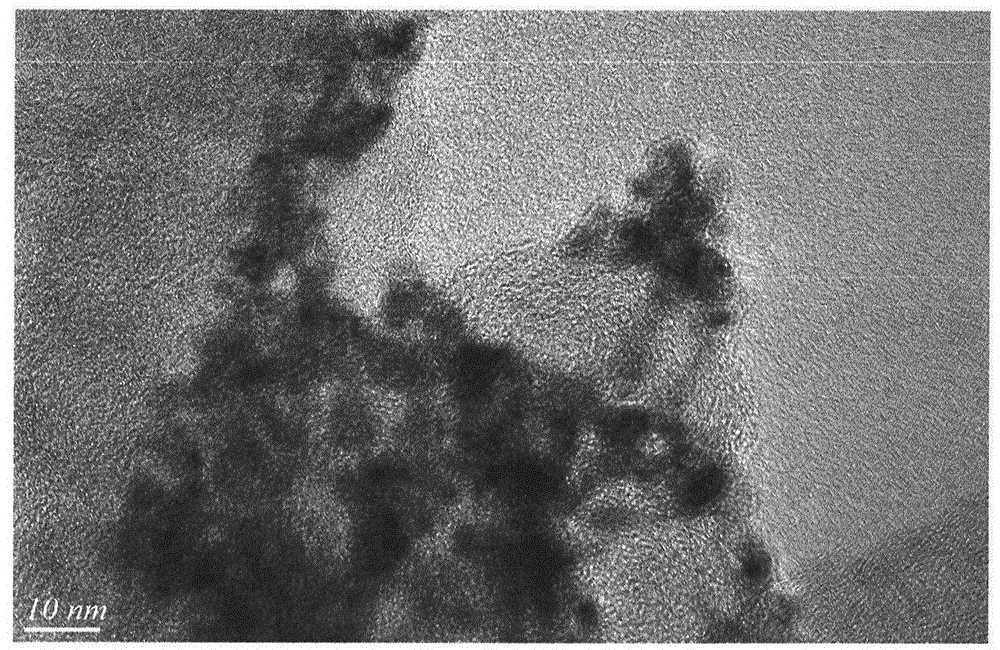

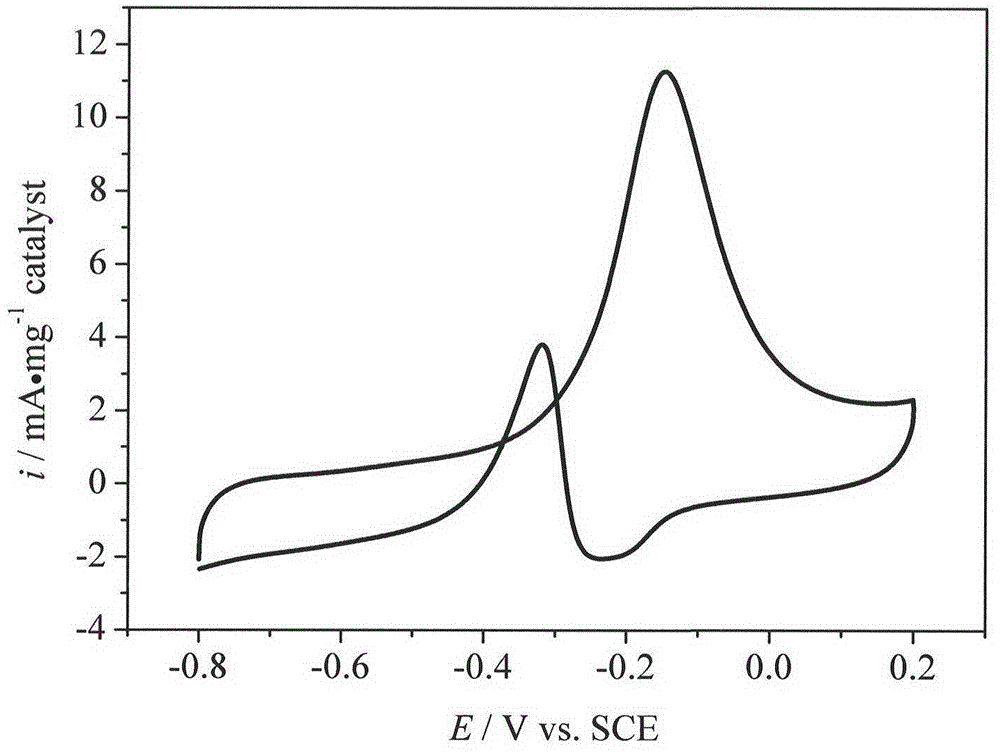

[0024] Embodiment 1: in the 2nd step of the preparation process, add 2.4ml ammonia water; in the 3rd step of the preparation process, NaBH 4 The dosage is 170 mg; other preparation conditions remain unchanged. The TEM picture of the obtained catalyst is as figure 1 shown. figure 1 It was shown that palladium nanoparticles were successfully supported on the surface of activated carbon support. figure 2 is the resulting catalyst in 0.1M KOH+1M CH 3 CV curves in OH mixed solution. The current density of the CV curves was normalized by the mass of the catalyst. From figure 2 It can be seen that the peak electrode potential of the current density of the electrochemical oxidation of methanol on the catalyst surface is -0.15V. At this potential, the current density of methanol electrochemical oxidation is 11.3mA·mg -1 catalyst.

Embodiment approach 2

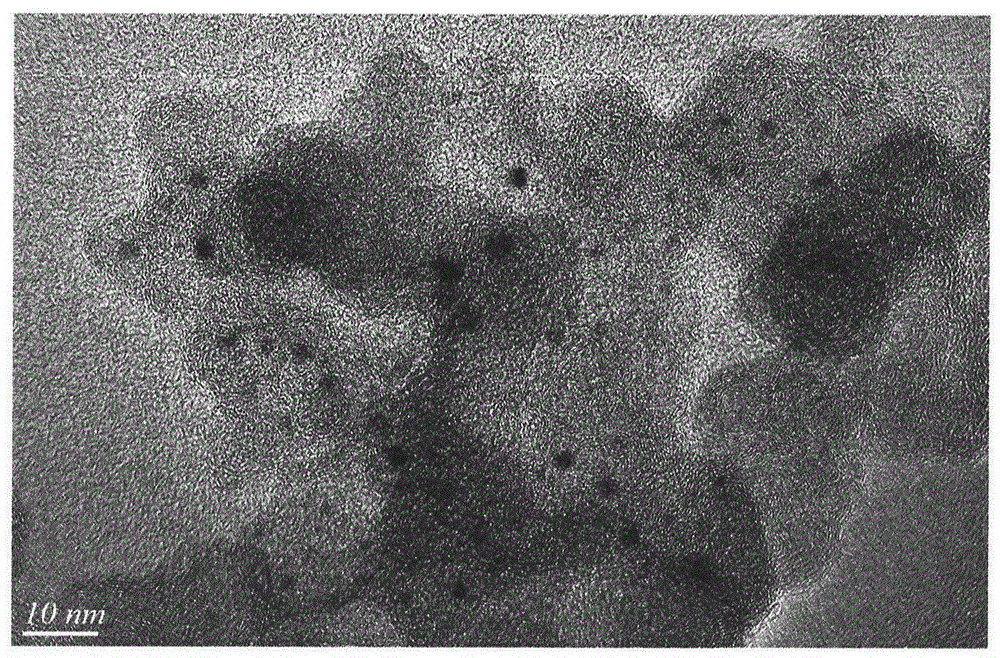

[0025] Embodiment two: in the 2nd step of the preparation process, add 3ml of ammonia water; in the 3rd step of the preparation process, NaBH 4 The dosage is 170 mg; other preparation conditions remain unchanged. The TEM picture of the obtained catalyst is as image 3 shown. image 3 It was shown that palladium nanoparticles were successfully loaded on the surface of activated carbon support. Figure 4 is the resulting catalyst in 0.1M KOH+1M CH 3 CV curves in OH mixed solution. The current density of the CV curves was normalized by the mass of the catalyst. From Figure 4 It can be seen that the peak electrode potential of the current density of the electrochemical oxidation of methanol on the catalyst surface is -0.15V. At this potential, the current density of the electrochemical oxidation of methanol is 16.6mA·mg -1 catalyst.

Embodiment approach 3

[0026] Embodiment three: in the 2nd step of the preparation process, add 3.6ml ammonia water; in the 3rd step of the preparation process, NaBH 4 The dosage is 170 mg; other preparation conditions remain unchanged. The TEM picture of the obtained catalyst is as Figure 5 shown. Figure 5 It was shown that palladium nanoparticles were successfully loaded on the surface of activated carbon support. Figure 6 is the resulting catalyst in 0.1M KOH+1M CH 3 CV curves in OH mixed solution. The current density of the CV curves was normalized by the mass of the catalyst. From Figure 6 It can be seen that the peak electrode potential of the current density of the electrochemical oxidation of methanol on the catalyst surface is -0.17V. At this potential, the current density of the electrochemical oxidation of methanol is 6.9mA·mg -1 catalyst.

[0027] Embodiment four: in the 2nd step of preparation process, add 3ml ammoniacal liquor; In the 3rd step of preparation process, NaBH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com