Test evaluation method for caking degree of RAP

An evaluation method and agglomeration technology, applied in the field of test evaluation of the degree of RAP agglomeration, can solve the problems of large test volume, inapplicability, and inapplicability of aggregates with a particle size larger than 4.75mm, etc. small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The present invention provides a kind of test evaluation method of RAP agglomeration degree, and method comprises the following steps:

[0029] Step A: RAP material 1 comes from the upper layer of Jiangsu Suhuaiyan Expressway. After sampling according to the sampling method recommended in the "Technical Specifications for Highway Asphalt Pavement Recycling" (JTG F41), put it in an oven at 60°C and dry it to constant weight;

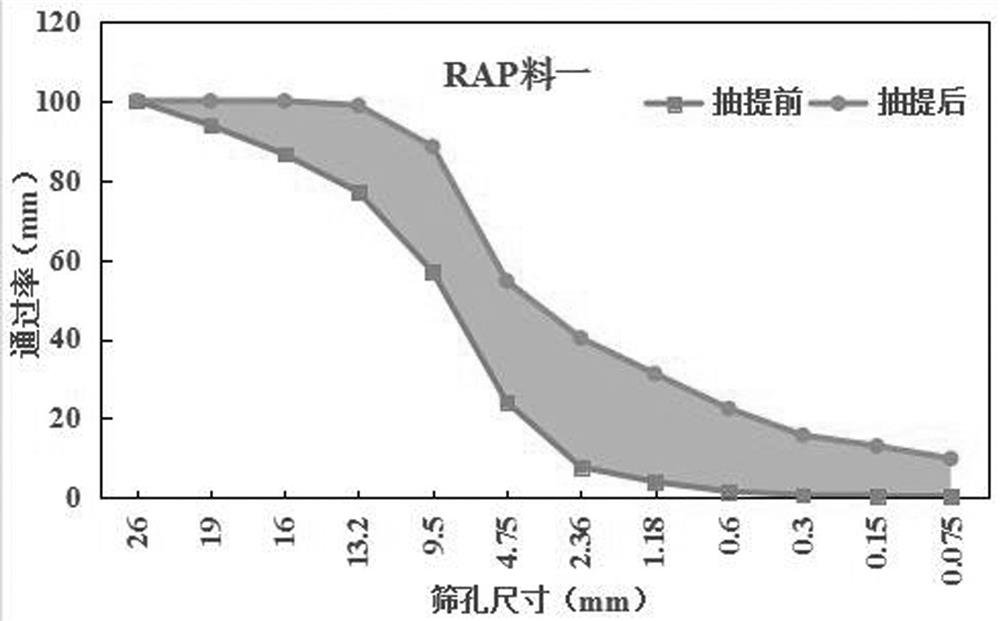

[0030] Step B: Weigh 1500 g of RAP that has been dried to constant weight in step A, and sieve directly. After the screening is completed, the extraction test is carried out in accordance with the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E20). The old aggregate obtained by extraction is dried in an oven at 105°C to constant weight, and the screening test is carried out after cooling. . According to the sieving results, calculate the pass rate of each sieve hole, take the sieve hole size as the equidistant abs...

Embodiment 2

[0035] The present invention provides a kind of test evaluation method of RAP agglomeration degree, and method comprises the following steps:

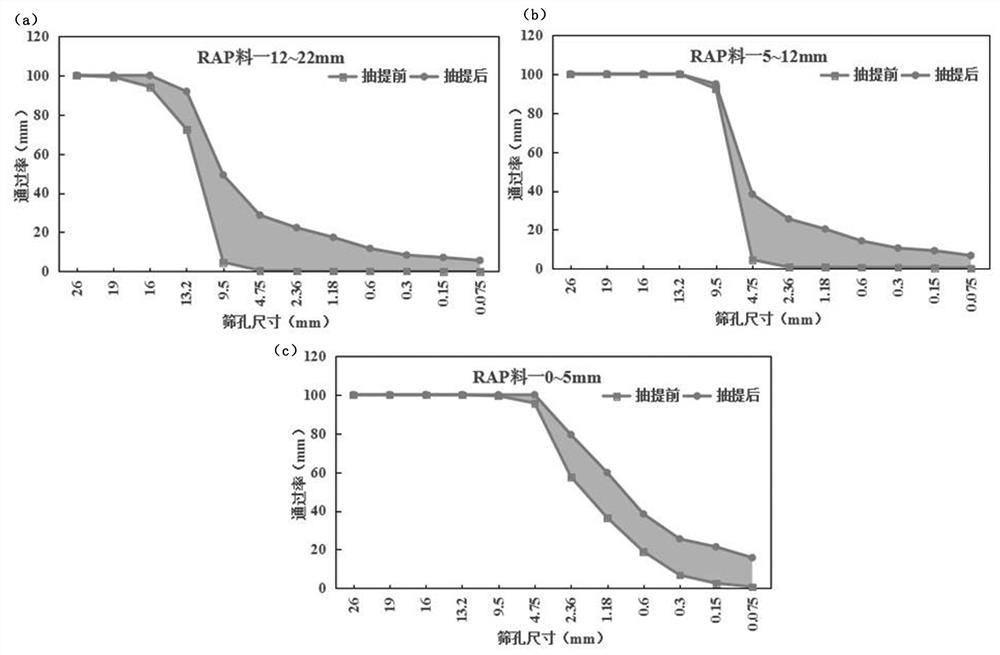

[0036] Step A: crush and sieve the RAP material in Example 1 into three grades of 12-22 mm (coarse), 5-12 mm (medium), and 0-5 mm (fine), according to the "Technical Specification for Recycling of Highway Asphalt Pavement" "(JTG F41) Recommended sampling method After sampling, place in an oven at 60°C and dry to constant weight;

[0037] Step B: Weigh 1500 g of coarse and medium RAPs and 1000 g of fine RAPs that have been dried to constant weight in step A, and sieve directly. After the screening is completed, the extraction test is carried out according to the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E20). The old aggregate obtained from the extraction is dried in an oven at 105°C to constant weight, and the screening test is carried out after cooling. . According to the sieving results, calcul...

Embodiment 3

[0042] The present invention provides a kind of test evaluation method of RAP agglomeration degree, and method comprises the following steps:

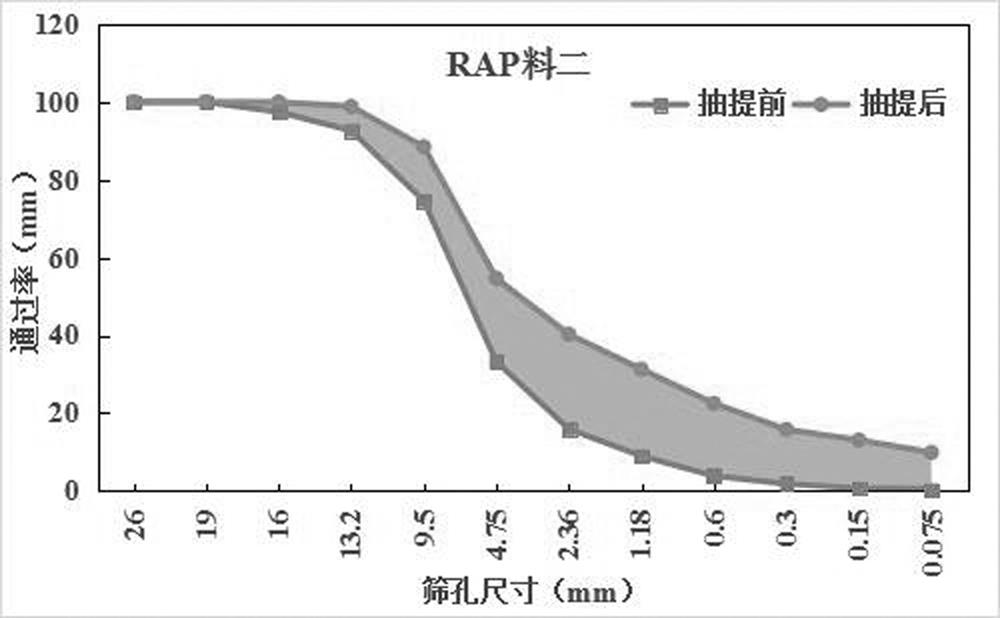

[0043] Step A: RAP material 2 comes from the upper layer of Jiangsu Ningsu-Xu Expressway. After sampling according to the sampling method recommended in the "Technical Specifications for Recycling of Highway Asphalt Pavement" (JTG F41), put it in an oven at 60°C and bake it to constant weight;

[0044] Step B: Weigh 1500 g of RAP that has been dried to constant weight in step A, and sieve directly. After the screening is completed, the extraction test is carried out in accordance with the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E20). The old aggregate obtained by extraction is dried in an oven at 105°C to constant weight, and the screening test is carried out after cooling. . According to the sieving results, calculate the pass rate of each sieve hole, take the sieve hole size as the equidistant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com