Airflow-assisted plasma seed treatment device

A plasma and auxiliary technology, applied in the direction of seed immunity, germination equipment, etc., can solve problems such as poor and easy accumulation treatment effect, and achieve the effect of improving utilization rate and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing:

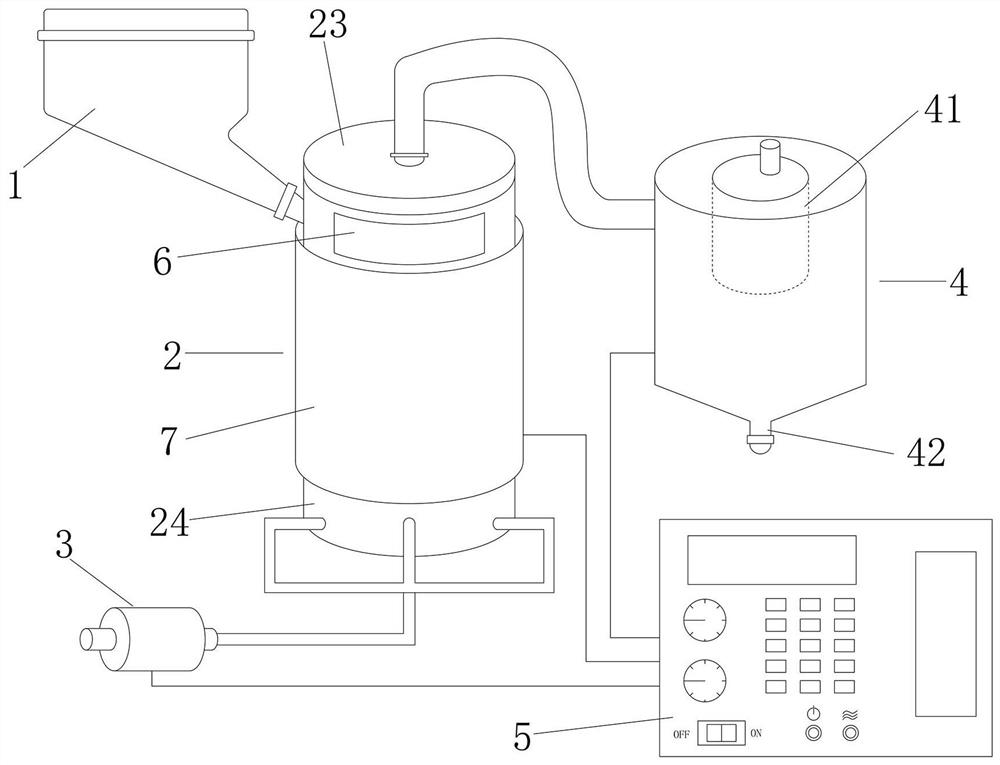

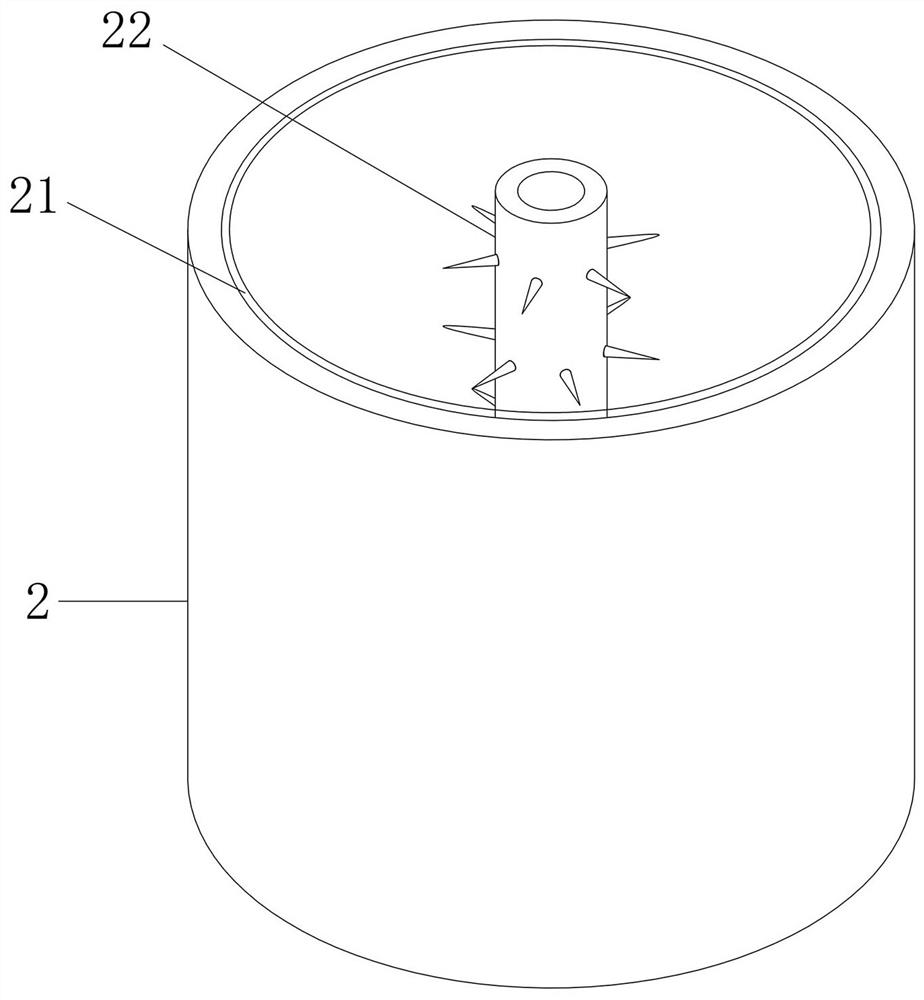

[0026] A kind of airflow-assisted plasma seed treatment machine, refer to Figure 1-2 As shown, it includes a feeding bin 1, a plasma processing chamber 2, an air intake auxiliary unit 3, a collecting bin 4 and a high-voltage power supply control module 5. The plasma processing chamber 2 is provided with two interfaces above and an air channel below. , the feed bin 1 and the collection bin 4 are respectively connected to the interface above the plasma processing chamber 2, the gas intake auxiliary unit 3 is connected to the gas channel below the plasma processing chamber 2, and the collection bin 4. A suction device 41 is arranged on the top of the interior, and a discharge port 42 is provided at the bottom of the collection bin 4. A control switch is provided on the discharge port 42. The air intake auxiliary unit 3, the plasma processing chamber 2 and the collection bin 4 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com