Preparation of aroma-enhancing and harm-reducing low-temperature fraction and application of aroma-enhancing and harm-reducing low-temperature fraction in cigarette heating

A low-temperature, fractional technology, applied in the field of heating cigarettes, can solve the problems of the destruction of heat-sensitive aroma-causing substances and the inability to retain tobacco aroma-causing components, and achieve the effects of improving taste, improving smoking quality, and modifying aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

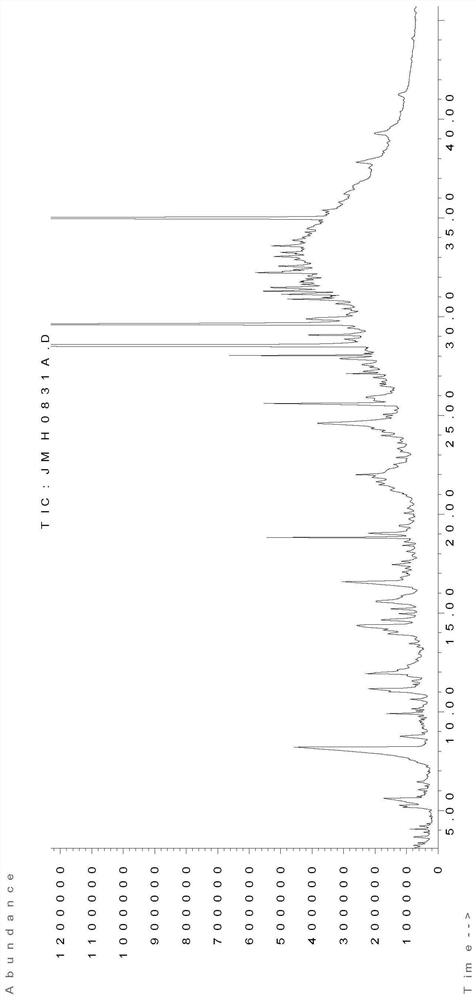

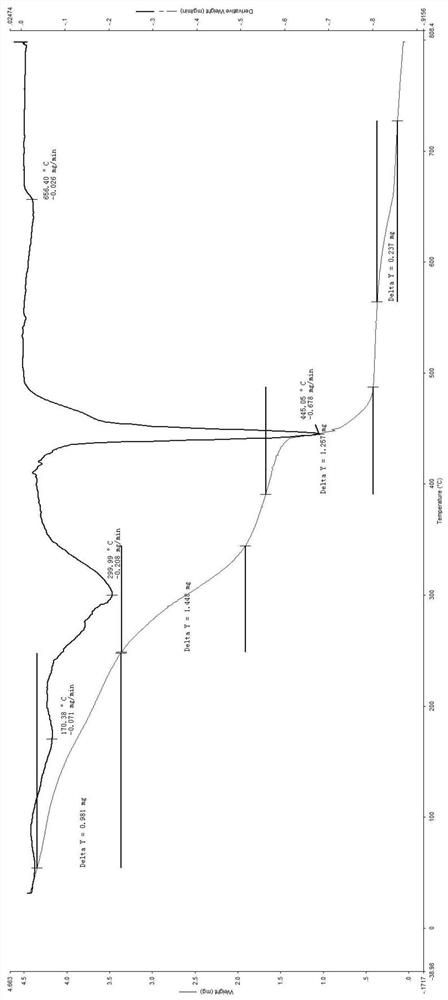

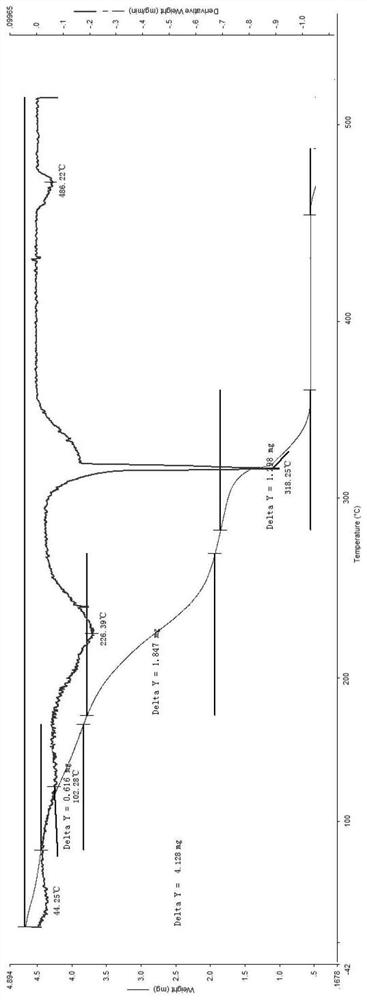

Image

Examples

Embodiment 1

[0029] A method for preparing a low-temperature distillate for increasing flavor and reducing harm, said preparation method comprising the following steps:

[0030] The Turkish oriental tobacco specifically adopts the Izmir oriental tobacco from the Izmir area.

[0031] Step 1 reflux extraction: reflux extraction of the mixed raw material of Turkish oriental tobacco leaves and guava leaves with ethyl acetate, the amount of ethyl acetate is 20 times of the raw material quality, the extraction time is 2 hours, and the extraction times are 3 times to obtain the initial extract;

[0032] The initial extract was fully dissolved with 3 times the mass of ethyl acetate at a temperature of 75°C under heating conditions, stirred evenly, frozen at -10°C for 12 hours, and filtered with suction to obtain the filtrate;

[0033] Step 2 Acid-base separation: extract the above-mentioned filtrate with 10wt% sodium carbonate solution, stand to separate the water phase, neutralize it with hydroch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com