Defoaming agent and preparation method thereof

A defoamer and emulsifier technology, applied in the field of defoamer and its preparation, can solve the problems of foam, water production rate drop, water production not up to standard, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

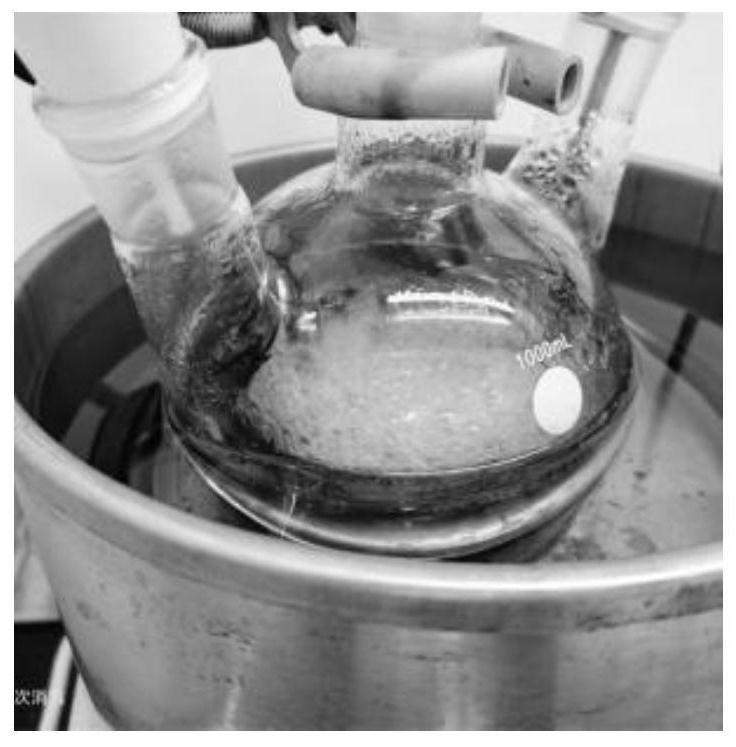

Image

Examples

Embodiment 1~7

[0028] The embodiment of defoamer of the present invention, its formula is as shown in table 1, and preparation method is as follows:

[0029] Add octylphenol polyoxyethylene ether phosphate and glycerol triphosphate into a three-necked flask, stir evenly, and react in an oil bath at 80°C for 80 minutes, then add dimethyl phosphosulfamic acid, allyl polyether, and water A, Add potassium hydroxide to adjust the pH to between 6 and 9, then increase the temperature to 105° C., and react for 40 minutes. Then add the higher carbon alcohol mixture and water B into the three-necked flask, stir evenly, add Tween 60, Span 80, and liquid paraffin, continue stirring, and react for 45 minutes to obtain the defoamer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com