Preparation process of anti-fracture high-stability elevator counterweight block

A preparation process and counterweight technology, which is applied in the field of high-stability elevator counterweight preparation technology, can solve problems such as easy fragmentation, elevator balance impact, safety hazards, etc., improve strength and stability, and ensure safe and stable operation. , the effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

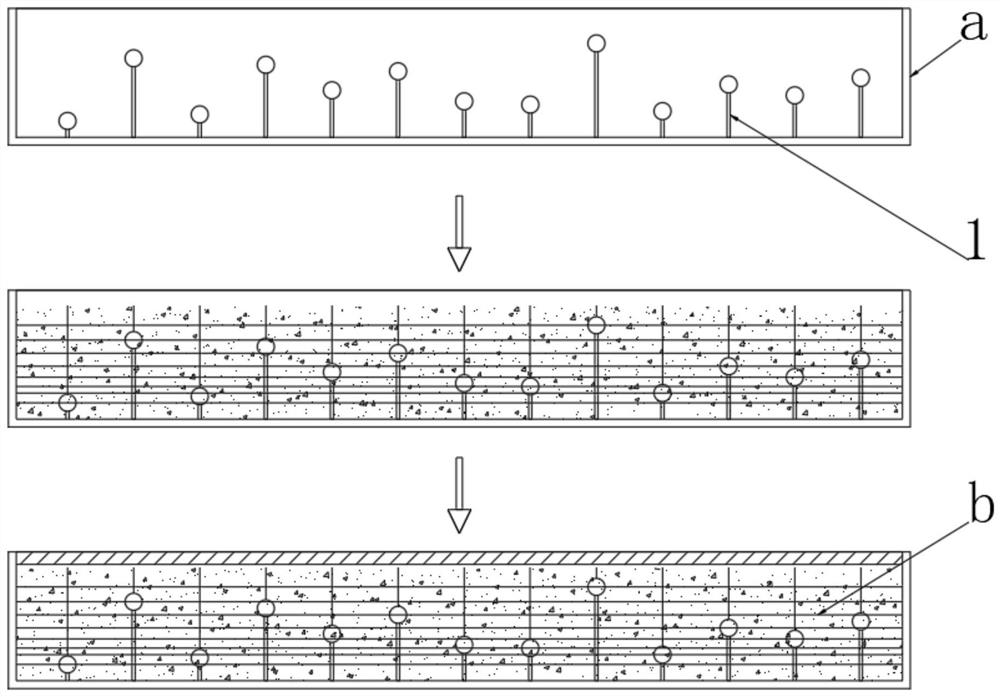

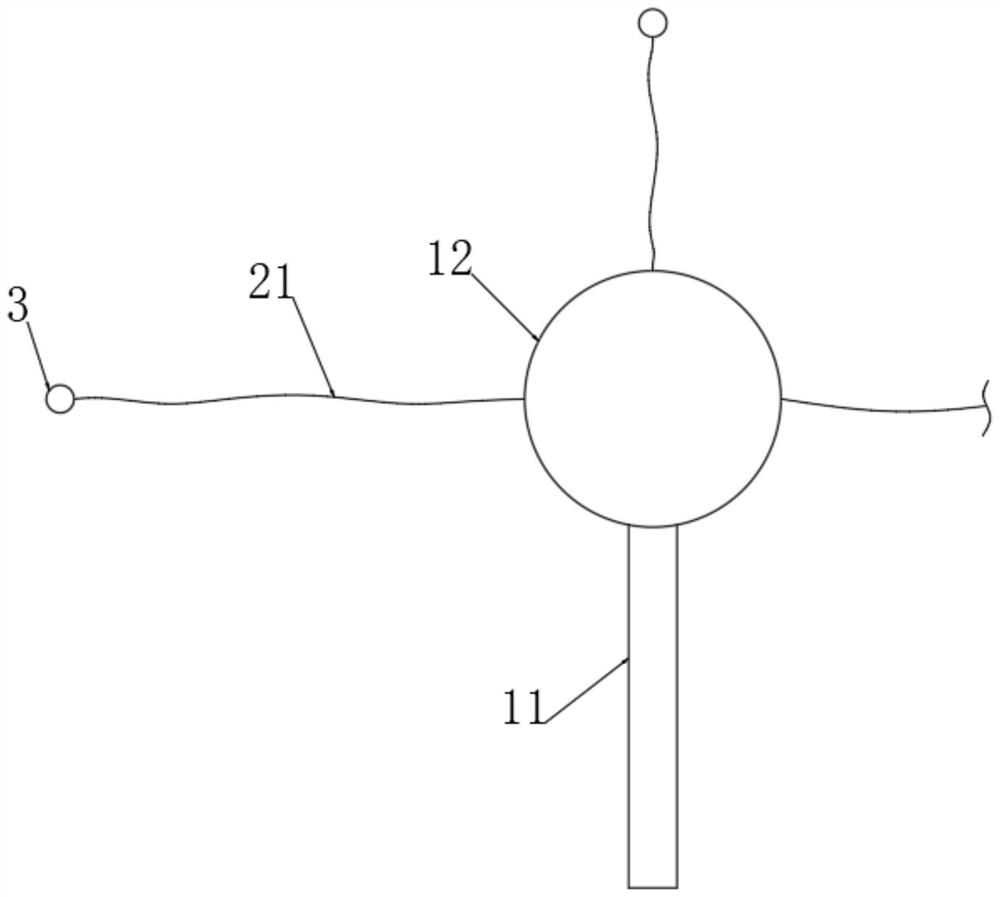

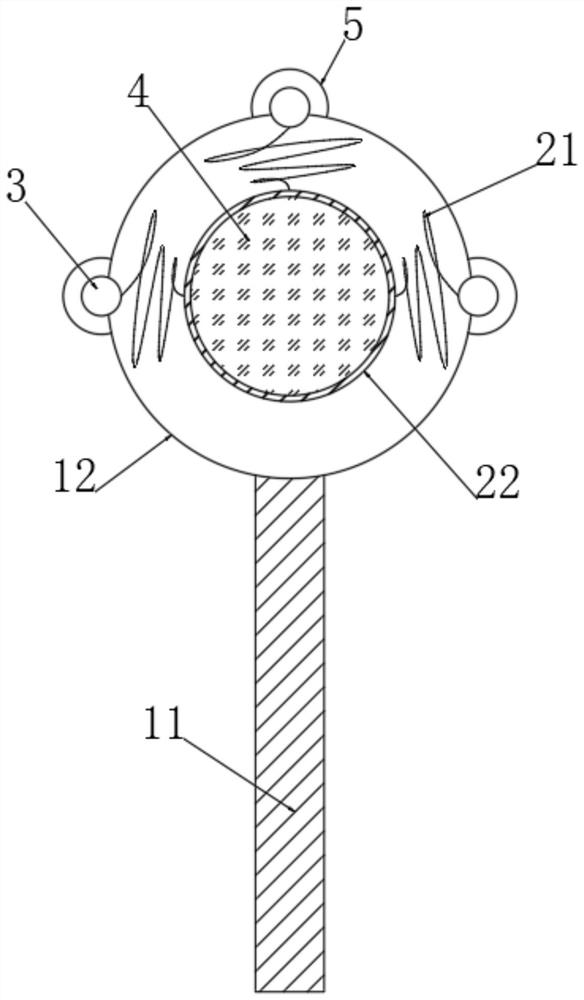

[0046] see figure 1 , in the figure, a represents the shell, b represents the wire drawing vein, a preparation process of a fracture-resistant and highly stable elevator counterweight, including the following steps:

[0047] S1. First, prepare the upper unsealed shell according to the outline of the target counterweight;

[0048] S2. Fix a plurality of drawing balls 1 on the inner bottom of the casing, and control the positions of the drawing balls 1 so as not to interfere with each other;

[0049] S3. Making slurry from the ingredients of the counterweight, and then pouring them into the casing. The ingredients include 30-50 parts of crushed slag of construction waste, 15-20 parts of water, 20-30 parts of metal waste powder and 10 parts by mass. -15 parts of cement;

[0050] S4. When the slurry in the shell is not solidified, the magnetic plate guides the drawing ball 1 to radiate outward for drawing, thereby forming criss-cross drawing veins in the slurry;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com