Heat insulation composite material and preparation method and application thereof

A technology of composite materials and mixtures, which is applied in the field of thermal insulation composite materials and their preparation, can solve the problems that the density and thermal conductivity cannot be effectively reduced, achieve remarkable material properties and process advantages, simple preparation methods, and broad market prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The embodiment of the present invention also provides a method for preparing a heat-insulating composite material. The method for preparing a heat-insulating composite material includes the following steps:

[0033] 1) Weigh the airgel micron particles in proportion and evenly disperse them in the adhesive resin to obtain the mixture;

[0034] 2) impregnating the high-silica material with the mixture, drying, and curing by hot pressing to obtain the heat-insulating composite material.

[0035] As another preferred embodiment of the embodiment of the present invention, in the preparation method of the heat-insulating composite material, the weighing of airgel micro-particles and uniform dispersion in the adhesive resin is realized by means of stirring, etc., Preferably, the adhesive resin is phenolic resin, and the airgel micron particles are dispersed in the phenolic resin by using a high-speed mixer under high-speed mechanical shearing. During the dispersion process, ...

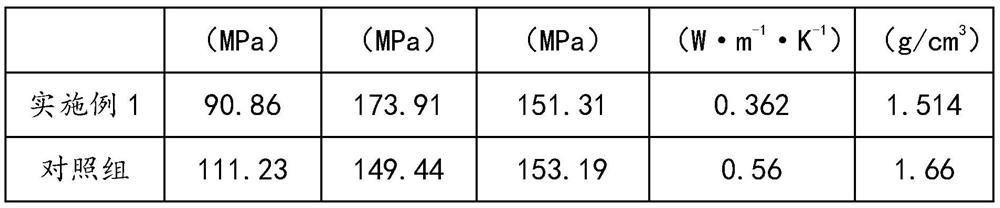

Embodiment 1

[0047] A kind of thermal insulation composite material, its preparation method specifically comprises the following steps:

[0048] 1) Preparation of silica airgel micro-particles: Pre-fabricated bulk silica airgel is used to prepare silica airgel micro-particles by mechanical ball milling. The ball milling process is to set the speed of the ball mill to 400r / min, the ball material occupies 1 / 3-1 / 2 of the volume of the tank, the ball milling time is 40min, and finally obtains silica airgel micron particles with a median particle size of 10-20μm and a density of 0.06-0.09g / cm 3 , thermal conductivity is 0.015-0.02W·m -1 ·K -1 .

[0049] 2) Uniform dispersion of silica airgel micro-particles in phenolic resin: use a high-speed mixer to disperse silica airgel micro-particles in phenolic resin under high-speed mechanical shearing (silica airgel The amount of glue micron particles added accounted for 1.0wt% of the weight of the phenolic resin) to obtain a mixture. During the...

Embodiment 2

[0054] Compared with Example 1, it is the same as Example 1 except that the amount of silica airgel micro-particles added accounts for 0.8wt% of the weight of the phenolic resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com