Bendable electrothermal film device based on graphene and preparation method thereof

An electric heating film, graphene technology, applied in the direction of electrical components, electric heating devices, heating element materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment discloses a graphene-based bendable electrothermal film device. The specific components and mass parts are shown in Table 1. The specific preparation method includes the following steps:

[0032] Step 1, adding the above-mentioned various components according to the mass fraction into polytetrafluoroethylene and ball milling to mix evenly;

[0033] Step 2. Apply the mixture obtained in Step 1 evenly on the surface of the polyimide base layer, and let it stand for defoaming;

[0034] Step 3: heat curing to obtain the target electrothermal film device with an area of 100mm×100mm.

[0035] Wherein, after the polyimide base layer described in step 2 is formed into a film, a rubbing roller is used for directional friction to obtain a rough guide protrusion.

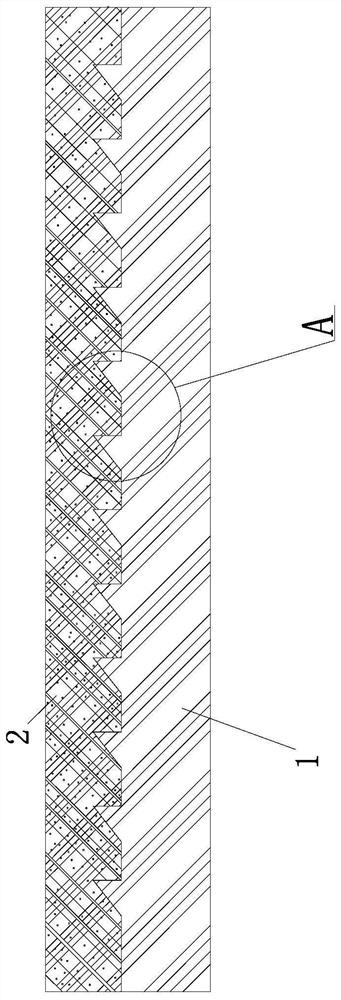

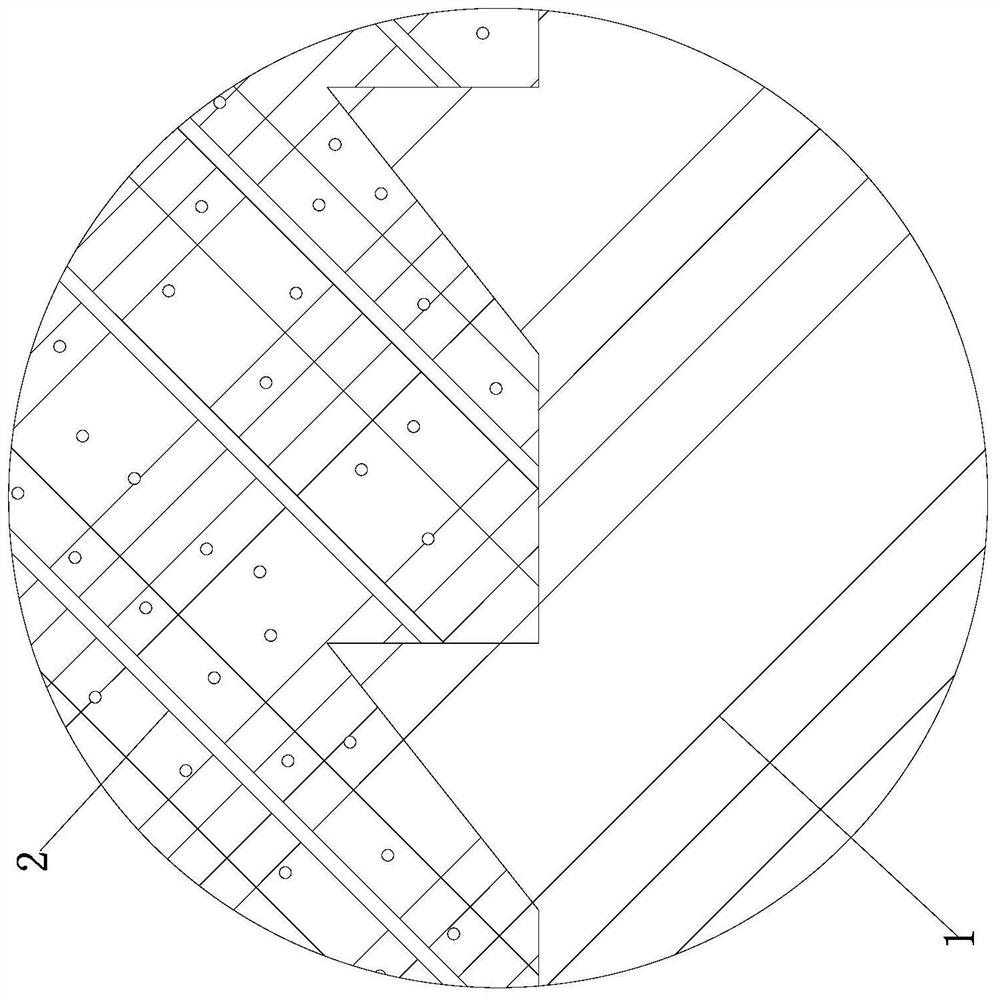

[0036] The cross-sectional structure of the obtained electrothermal film is detailed in figure 1 and figure 2 As shown, it includes a polyimide base layer 1 and an organic electrothermal film 2 coa...

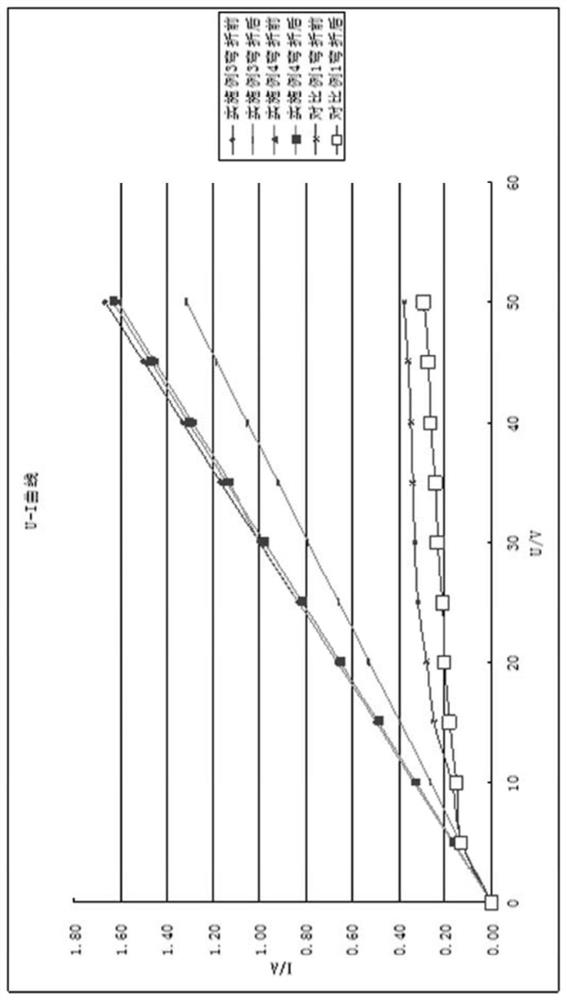

Embodiment 2

[0038] The main differences between this embodiment and embodiment 1 are shown in Table 1.

Embodiment 3

[0040] The main differences between this embodiment and embodiment 1 are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com