Integrated packaging electrolytic capacitor module and inverter assembly of 48v bsg inverter

A technology of electrolytic capacitors and capacitor modules, which is applied in the direction of electrolytic capacitors, capacitors, capacitor terminals, etc., can solve the problems of strict BSG system requirements, small installation space, and good seismic performance, so as to avoid capacitor swing failure, improve seismic performance, The effect of high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

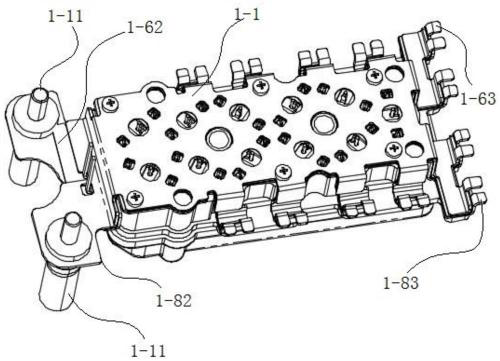

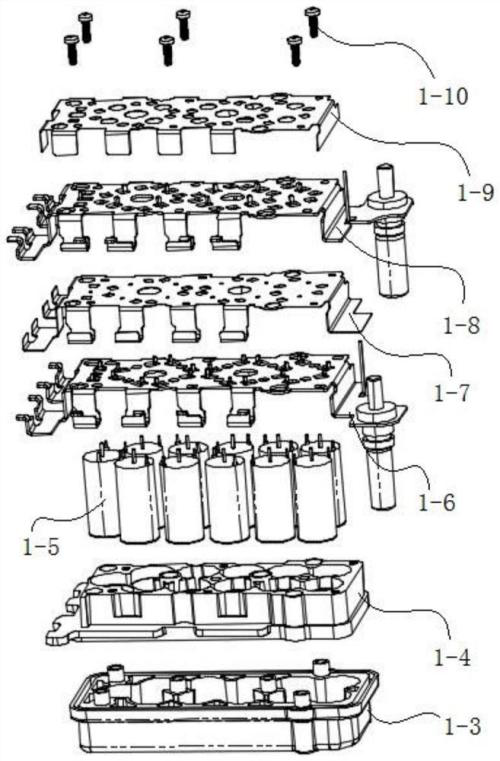

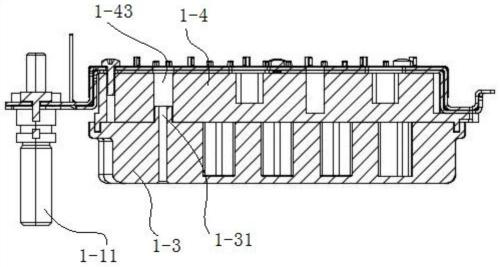

[0067] combine Figure 1 to Figure 4 As shown, an integrated packaged electrolytic capacitor module of a 48V BSG inverter includes heat sink 1-3, capacitor bracket 1-4, electrolytic capacitor 1-5, negative busbar 1-6, positive busbar 1- 8 etc. Negative busbar terminals 1-63 and a negative busbar connecting arm 1-62 are provided around the negative busbar 1-6, and a through hole for installation is opened on the negative busbar connecting arm 1-62, and the large end of the output screw rod 1-11 passes through Pass through the installation through hole of the negative busbar connecting arm 1-62 and fix it by welding. There are positive busbar terminals 1-83 and a positive busbar connecting arm 1-82 around the positive busbar 1-8, the positive busbar connecting arm 1-82 is provided with an installation through hole, and the large end of the output screw 1-11 is passed through Pass through the installation through hole of the positive busbar connecting arm 1-82 and fix it by wel...

Embodiment 2

[0080] combine Figure 6 to Figure 8 As shown, an inverter assembly includes an integrated package electrolytic capacitor module 1 of a 48V BSG inverter described in Embodiment 1, and also includes a bracket and a power module 2, a heat dissipation module 3, and a PCB module 4 , Motor shield 7 etc.

[0081] The heat dissipation module 3 includes a heat dissipation plate 3-1, one end of the heat dissipation plate 3-1 is provided with a plug 3-3, the heat dissipation plate 3-1 is provided with a capacitor module installation slot 3-4, and the integrated package electrolytic capacitor module 1 is installed on the capacitor module Install in slot 3-4. The heat dissipation plate 3-1 is provided with a capacitor module positioning column II 3-2 corresponding to a part of the capacitor positioning hole I1-43 on the integrated packaged electrolytic capacitor module 1, and the through hole in the center of this part of the capacitor positioning hole I1-43 is used as a capacitor Modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com