Inverted light-emitting diode

A light-emitting diode, flip-chip technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of increased resistance, increased electrode light absorption, light blocking area, and reduced antistatic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

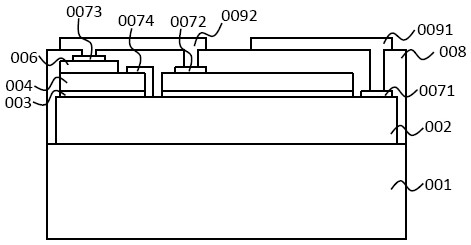

[0030] attached figure 1 A flip-chip light emitting diode is shown, which has a transparent substrate 001, a first semiconductor layer 002, a light emitting layer 003, a second semiconductor layer 004, a third semiconductor layer 006, the third semiconductor layer 006 is etched, the second semiconductor layer 004 The luminescent layer 003 forms three independent regions; the third semiconductor layer 006, the second semiconductor layer 004 and the luminescent layer 003 of the first region I are etched away to expose the first semiconductor layer 002; the second semiconductor layer 002 of the second region II is etched away The third semiconductor layer 006, exposing the second semiconductor layer 004; etching and removing part of the third semiconductor layer 006 in the third region III, exposing part of the second semiconductor layer 004; setting the first semiconductor layer 002 on the surface of the first region I A contact electrode 0071, a second contact electrode 0072 on...

Embodiment 2

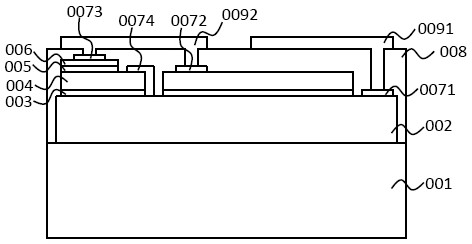

[0043] attached Figure 11 Another flip-chip light-emitting diode is shown, which has a transparent substrate 001, a first semiconductor layer 002, a light-emitting layer 003, a second semiconductor layer 004, a contact layer 0041, a barrier layer 005, a third semiconductor layer 006, and the third semiconductor layer is etched. The semiconductor layer 006, the barrier layer 005, the contact layer 0041, the second semiconductor layer 004 and the light emitting layer 003 form three independent regions; the third semiconductor layer 006 in the first region I, the barrier layer 005, the contact layer 0041, The second semiconductor layer 004 and the light emitting layer 003, exposing the first semiconductor layer 002; etching and removing the third semiconductor layer 006, barrier layer 005 and part of the contact layer 0041 in the second region II, exposing the second semiconductor layer 004 and the contact layer 0041; Part of the third semiconductor layer and the second semicond...

Embodiment 3

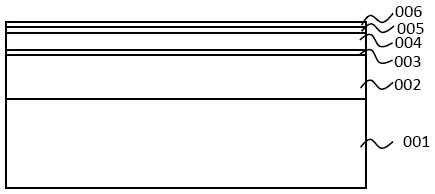

[0046] attached image 3 Another flip-chip light-emitting diode of the present invention is shown, which has a transparent substrate 001, a first semiconductor layer 002, a light-emitting layer 003, a second semiconductor layer 004, and a third semiconductor layer 006; the third semiconductor layer in this embodiment 006 is formed on the upper surface of the second semiconductor layer 004 by diffusion technology. Etching the third semiconductor layer 006, the second semiconductor layer 004, and the light-emitting layer 003 to form three independent regions; etching and removing the third semiconductor layer 006, the second semiconductor layer 004, and the light-emitting layer 003 in the first region I, exposing the first The semiconductor layer 002; etching and removing the third semiconductor layer 006 in the second region II, exposing the second semiconductor layer 004; etching and removing part of the third semiconductor layer 006 in the third region III, exposing part of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com