Positioning structure of rotating shaft axial detection piece, and motor

A technology for positioning structures and detection parts, applied in structural connections, electrical components, electromechanical devices, etc., can solve the problems of rotor dynamic balance damage, failure to ensure that the axial detection device can be installed back to its original position, and precision nuts, etc. To achieve the effect of eliminating motor vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

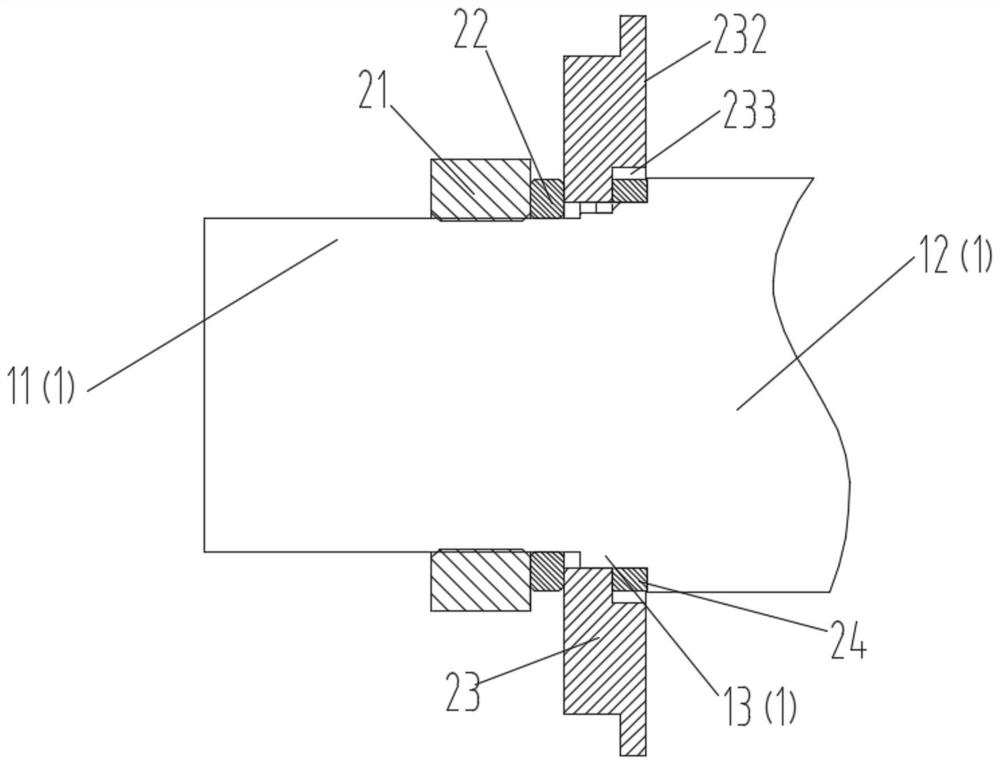

[0022] see in conjunction Figure 1 to Figure 4 As shown, according to the embodiment of the present invention, there is provided a positioning structure for the axial detection part of the rotating shaft, including the rotating shaft 1, and the rotating shaft 1 includes a first shaft section 11 and a second shaft section 12 arranged adjacently along its axial direction (It can be understood that the two are coaxially arranged), the diameter of the second shaft segment 12 is larger than the diameter of the first shaft segment 11 so that when the second shaft segment 12 faces a side of the first shaft segment 11 The side forms a positioning shoulder. Along the axial direction from the first shaft section 11 to the second shaft section 12, the first shaft section 11 is sequentially and adjacently fitted with threaded fasteners 21 (such as present There are precision nuts in the art), the first gasket 22, the axial detection part 23 (the axial displacement detection part such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com