Composition and method for fabrication of nickel interconnects

A composition and interconnection technology, applied in the field of metal electrodeposition, can solve the problems of reducing the performance and reliability of integrated circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] Example 1: Preparation of an exemplary nickel electrolyte composition comprising the following components:

[0113] MacDermid Enthone Nickel Sulfamate LIQ 20 Concentrate (150g / L Ni) - 485mL / L

[0114] Sulfamic acid-1.7g / L

[0115] Boric acid-30g / L

[0116] Nickel bromide solution-55mL / L

[0117] 08-0.5g / L

[0118] MacDermid Enthone Brightener 63 (Accelerator or Depolarizer) - 3mL / L

[0119] The pH of the electrolyte was adjusted to 4.0 using a 50 g / L sulfamic acid solution, and the electrolyte was heated to 55°C. A 2 cm x 2 cm coupon with a 23 micron diameter and 30 micron deep via with a copper seed layer and patterned photoresist was taped to a stainless steel coupon holder, immersed in electrolyte and charged at a current density of 5 ASD And the electrode was rotated at a rotation rate of 100 RPM for 10 minutes for electroplating. The photoresist was stripped, and a SEM cross section showed that the via was filled to about 50%.

Embodiment 2

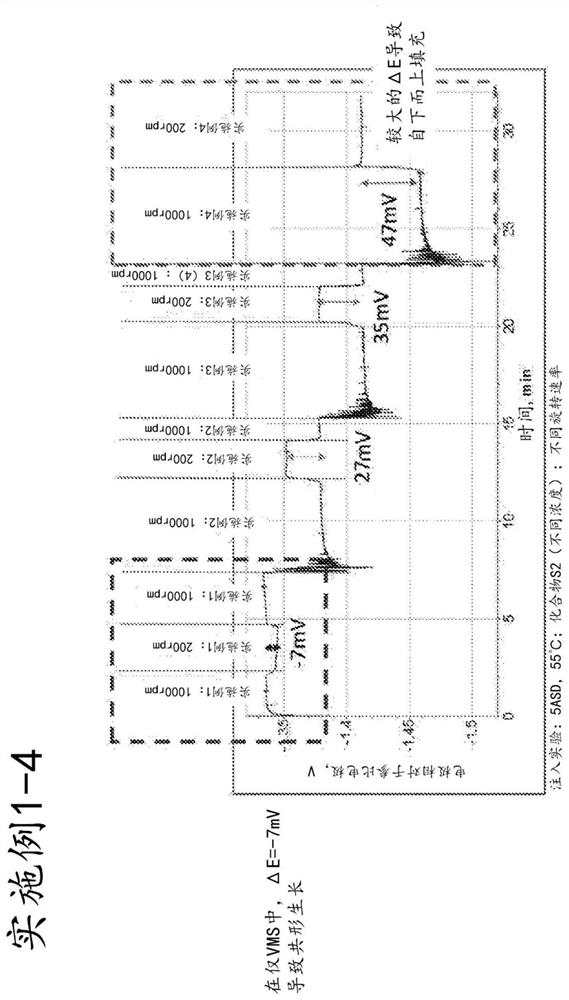

[0120] Example 2: The same electrolyte as in Example 1 was prepared by adding 2 mL / L of compound S2 (a heterocyclic betaine (polarizer) with a molecular weight less than 500). The photoresist was stripped, and a SEM cross-section showed that the via was filled to about 60%.

Embodiment 3

[0121] Example 3: The same electrolyte as in Example 1 was prepared by adding 4 mL / L of compound S2. The photoresist was stripped, and a SEM cross-section showed that the via was filled to about 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com