Method for preparing magnetic multi-effect adsorbent by dry method of enzymatic hydrolysis residue

An enzymatic hydrolysis residue and adsorbent technology, applied in the field of materials, can solve the problems of high cost and complicated operation, and achieve the effects of excellent adsorption effect, simple preparation method, and cheap and easy-to-obtain raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

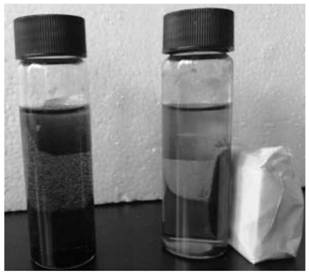

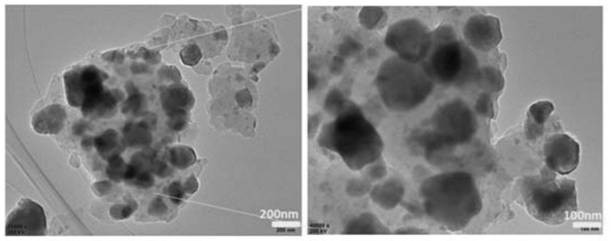

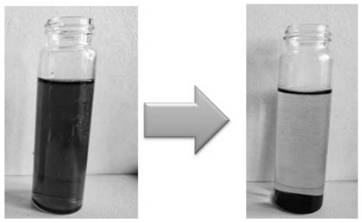

[0028] The method and application of the magnetic multi-effect adsorbent prepared by the dry method of the enzymatic hydrolysis residue, the specific steps are as follows:

[0029] Step 1: The corncob enzymatic hydrolysis residue with a lignin content of 86% is centrifuged and washed with distilled water until neutral, dried, and stored in a dry environment at room temperature for later use.

[0030] Step 2: Take the above-obtained enzymatic hydrolysis residue and Co 3 O 4 The nanoparticles were uniformly mixed at a mass ratio of 5:1, and preheated at a temperature of 100°C for 3 hours to obtain the pretreated material.

[0031] Step 3: Transfer the processed material to a ball mill, place the ball mill in a planetary ball mill, and perform mechanical ball milling for 5 hours at a speed of 80 revolutions / min and 300 revolutions / min.

[0032] Step 4: Open the treated ball-milling jar, take out the material in the jar, and sieve and separate the ball-milled zirconium beads to ...

Embodiment 2

[0035] Example 2 (comparative example, without adding magnetic nanoparticles):

[0036] The method and application for preparing multi-effect adsorbent by using enzymolysis residue dry method, the specific steps are as follows:

[0037] Step 1: The corncob enzymatic hydrolysis residue with a lignin content of 89% is centrifuged and washed with distilled water until neutral, dried, and stored in a dry environment at room temperature for later use.

[0038] Step 2: adding the enzymatic hydrolysis residue obtained above into a ball mill, and preheating for 3 hours at a temperature of 100° C. to obtain a pretreated material.

[0039] Step 3: Transfer the processed material to a ball mill, place the ball mill in a planetary ball mill, and perform mechanical ball milling for 5 hours at a speed of 80 revolutions / min and 300 revolutions / min.

[0040] Step 4: Open the treated ball-milling jar, take out the material in the jar, and sieve and separate the ball-milled zirconium beads to ...

Embodiment 3

[0044] The method and application of the magnetic multi-effect adsorbent prepared by the dry method of the enzymatic hydrolysis residue, the specific steps are as follows:

[0045] Step 1: The enzymatic hydrolysis residue of wheat straw with a lignin content of 81% is centrifuged and washed with distilled water until neutral, dried, and stored in a dry environment at room temperature for later use.

[0046] Step 2: Mix the above-obtained enzymatic hydrolysis residue and NiO nanoparticles uniformly at a mass ratio of 1:4, and preheat at 80° C. for 5 hours to obtain a pretreated material.

[0047] Step 3: Add the pretreated material to the ball mill, then place the ball mill in the planetary ball mill, and perform mechanical ball milling for 4 hours at a speed of 60 revolutions / min and 200 revolutions / min;

[0048] Step 4: Open the treated ball-milling jar, take out the material in the jar, and sieve and separate the ball-milled zirconium beads to obtain the magnetic multi-effec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com