Outer surface treatment device for casting machining and working method thereof

A technology for treating devices and external surfaces, which is applied to devices for coating liquids on surfaces, pre-treatment surfaces, coatings, etc., and can solve problems such as single function, poor coating effect, and easy precipitation of coatings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the content easier to understand, the following will be further described in detail based on specific embodiments and in conjunction with the accompanying drawings;

[0033] An external surface treatment device and working method for casting processing, which solves the problems of single function, slow coating forming speed, easy precipitation of coating and poor coating effect in the related technology The problem is that the forming speed of the coating is relatively fast, the coating will not precipitate, and the coating effect is relatively good. The general idea is as follows:

[0034] One implementation mode:

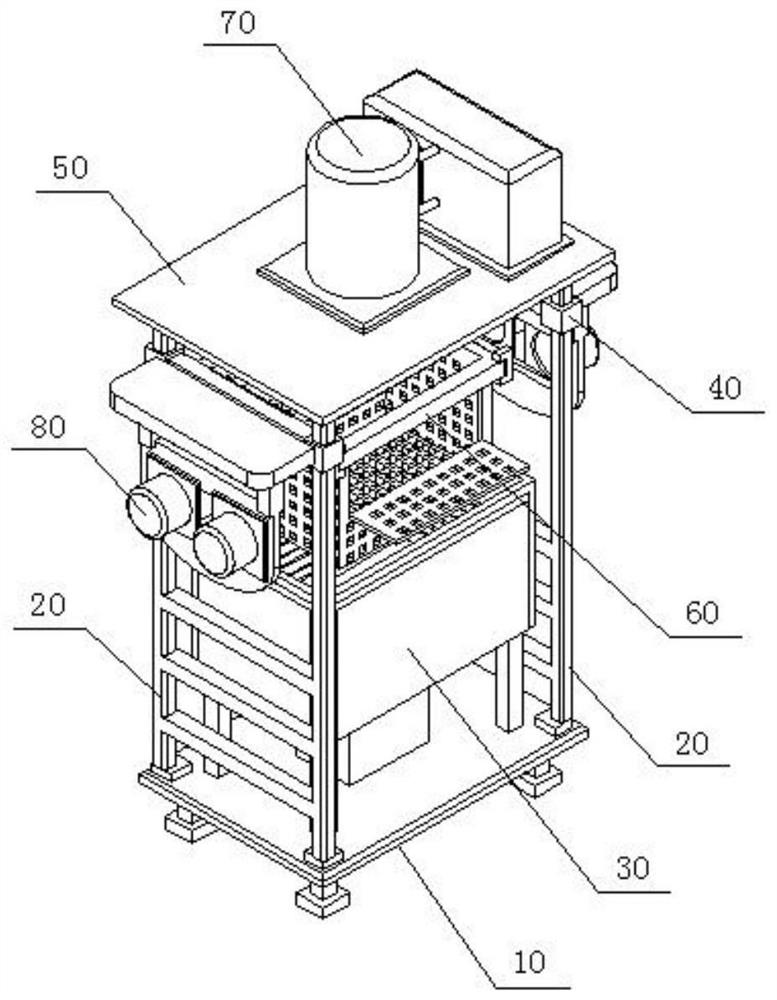

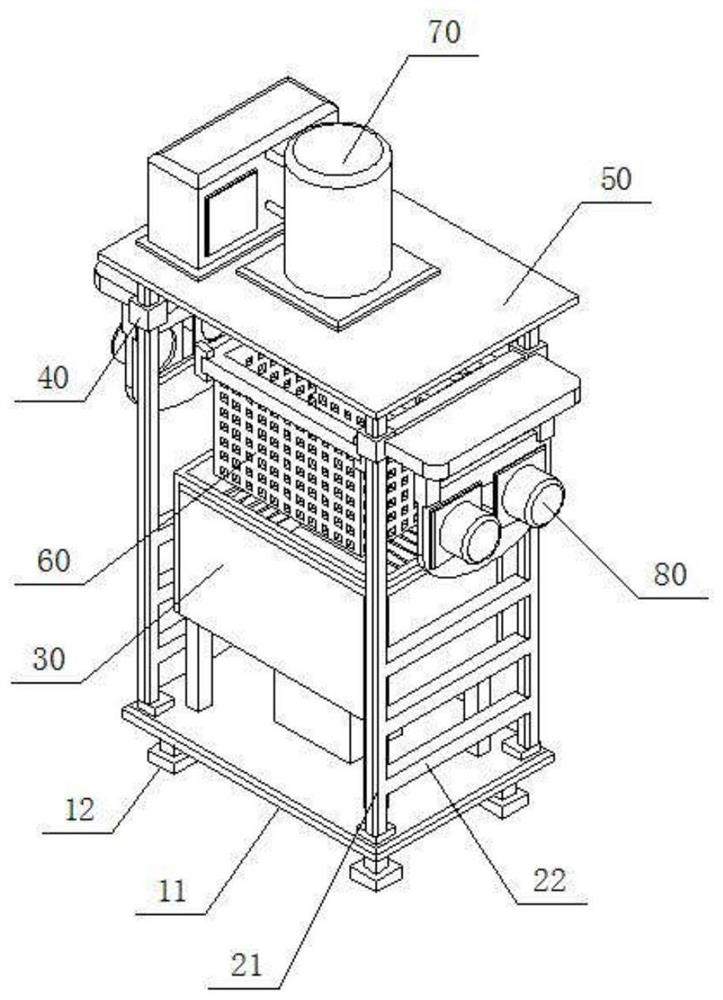

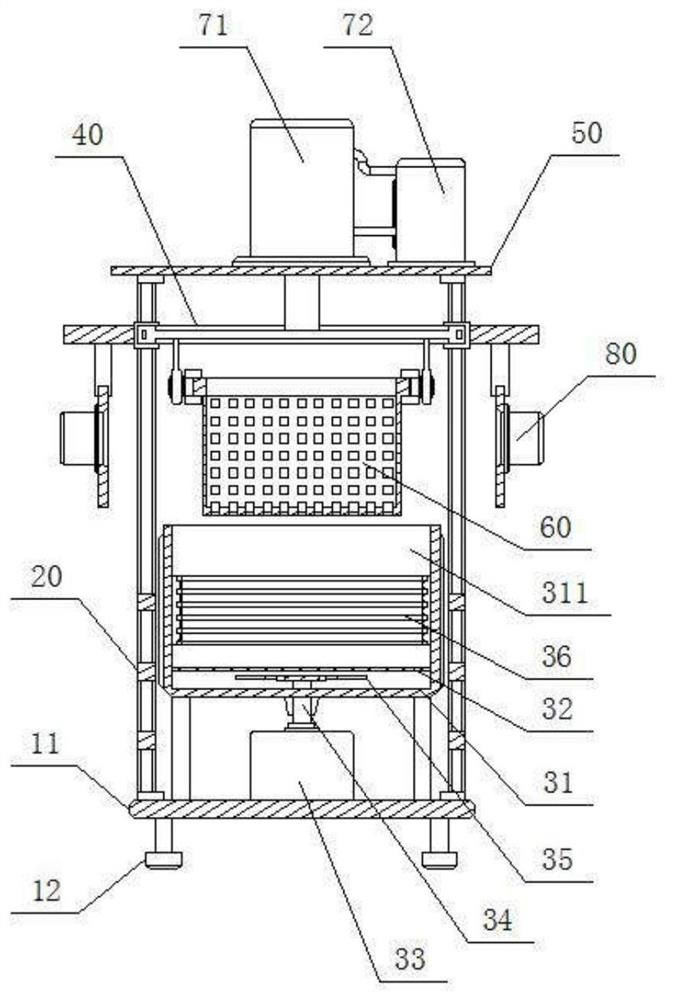

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown; A kind of external surface treatment device and working method thereof for casting processing, described external surface treatment device for casting processing, comprising:

[0036] base 10;

[0037] Two first supports 20 are symmetrically connected to the base 10; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com