Novel crushing and cleaning device for high-risk waste barrel

A technology for cleaning devices and waste barrels, which is applied in the direction of solid waste removal, shearing devices, and cleaning hollow objects, etc., and can solve problems such as inability to dump out of oil barrels, leakage of environmental hazards, and serious injury to workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

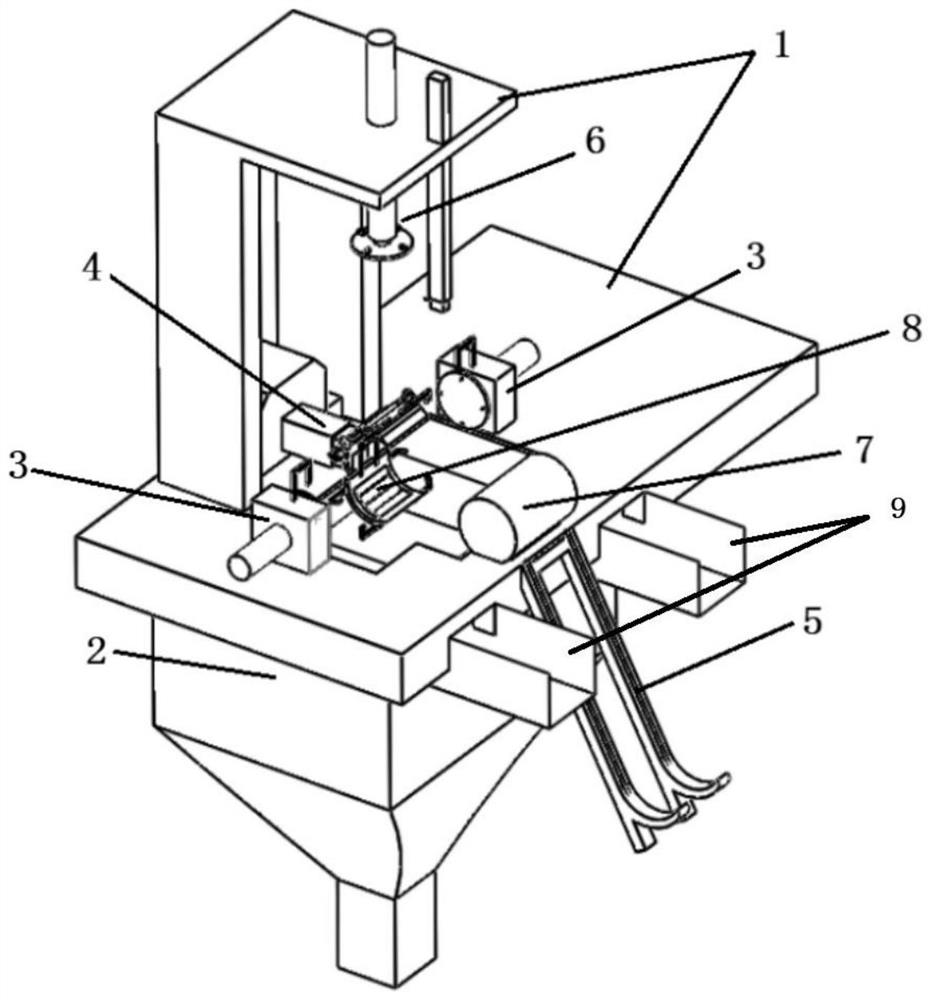

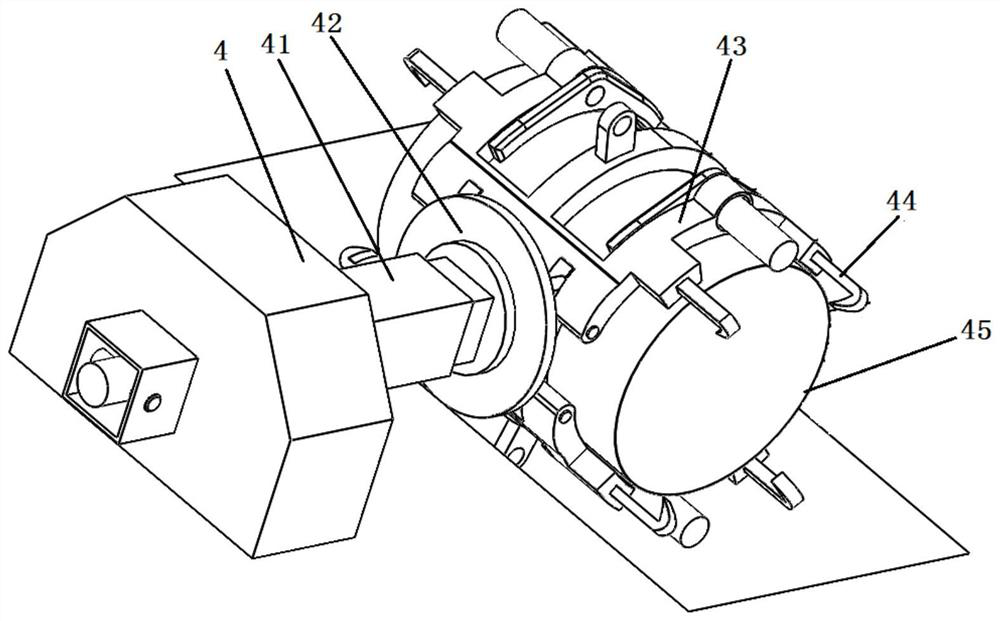

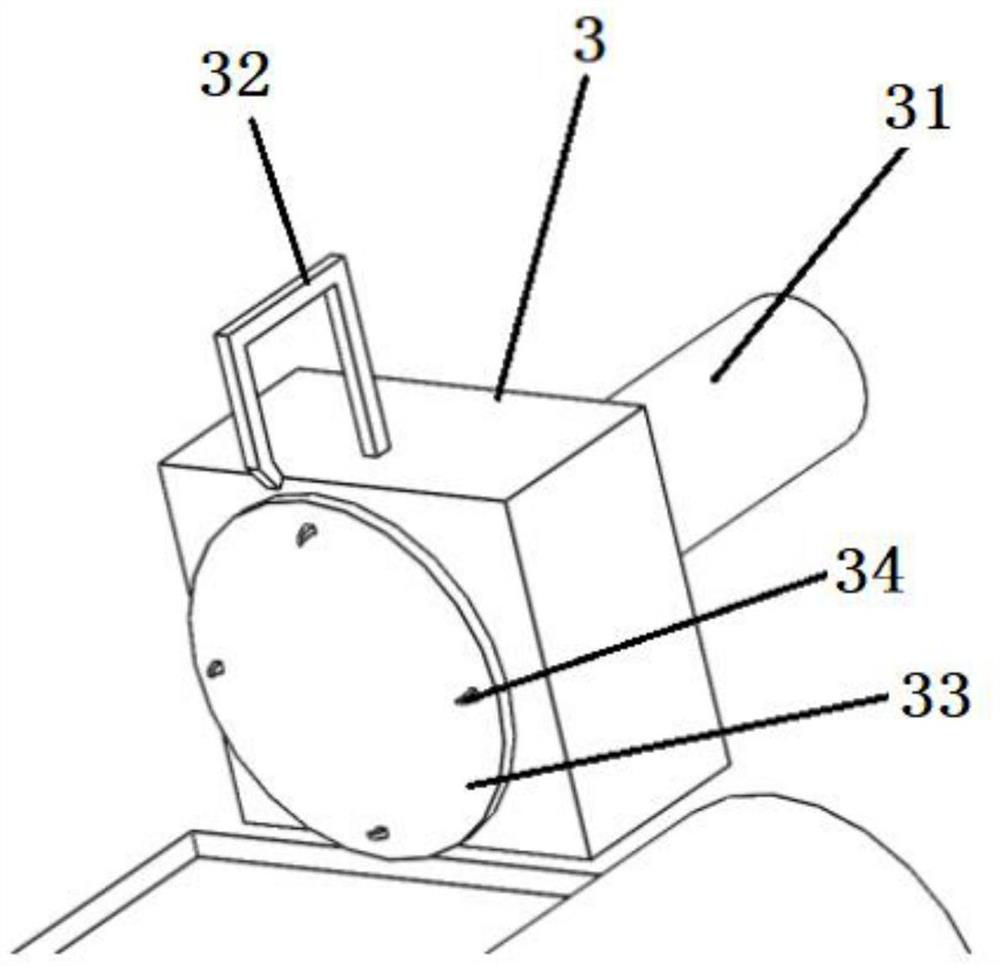

[0020] combined with Figure 1-4 , the specific embodiment of the present invention is described as follows:

[0021] like figure 1 , 2 As shown in , 3 and 4, a new type of high-risk waste drum cleaning device includes a body 1, the body 1 is composed of an upper platform, a lower platform and a connecting column connecting the upper platform and the lower platform, and the lower platform is provided with a waste hole , below the waste hole of the lower platform, a waste recovery bin 2 and a bung lid recovery tank 9 are arranged, a bung lid cutting machine 3 is respectively arranged on the lower platform on both sides of the waste hole, and a clamping mechanism is arranged on the connecting column on the rear side of the waste hole. The arm 4 is provided with a waste barrel conveyor 5 on the lower platform at the front side of the waste hole, and a waste barrel cleaning device 6 is arranged above the waste hole, and the waste barrel cleaning device 6 is installed on the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com