Preparation method of large-size TC17 titanium alloy beta-forged blisk forge piece

A TC17, integral blisk technology, applied in metal processing equipment, forging/pressing/hammering machinery, manufacturing tools, etc., can solve the problems of high production cost, tensile strength can not meet design requirements, high mold cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] Billet: α+β type two-phase titanium alloy, for example: titanium alloy with Chinese material grade TC17.

[0042]Step 1: The temperature at the phase transition point of the TC17 titanium alloy bar used is 900°C as measured by HB 6623.2.

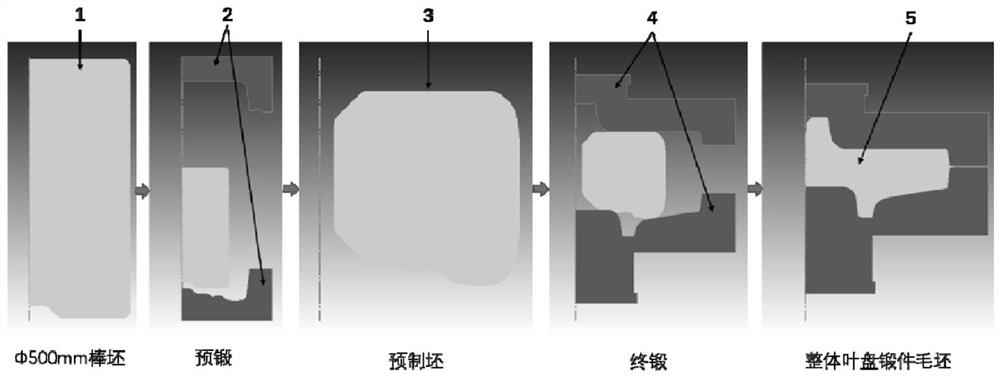

[0043] Step 2: If figure 1 As shown, the TC17 titanium alloy Φ500mm bar is blanked according to the double size (645mm) and processed into a bar blank 1 with positioning holes. After the bar blank 1 is preheated to 50°C, Ti-5 glass lubricant is sprayed on its surface. The end of the billet 1 with the positioning hole faces down and is heated to 860°C, and the holding time is calculated based on the effective section thickness of the billet 1 of 0.6min / mm.

[0044] Step 3: Preheat the upper and lower pre-forging cavity molds at 2 to 350°C, spray lubricant on the cavity of the mold 2, transfer the billet 1 heated in step 2 to the lower pre-forging cavity mold and quickly complete the positioning, and place the billet on the The end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com