Metal bar cutting device for electroslag metallurgy and adding system of metal bar cutting device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

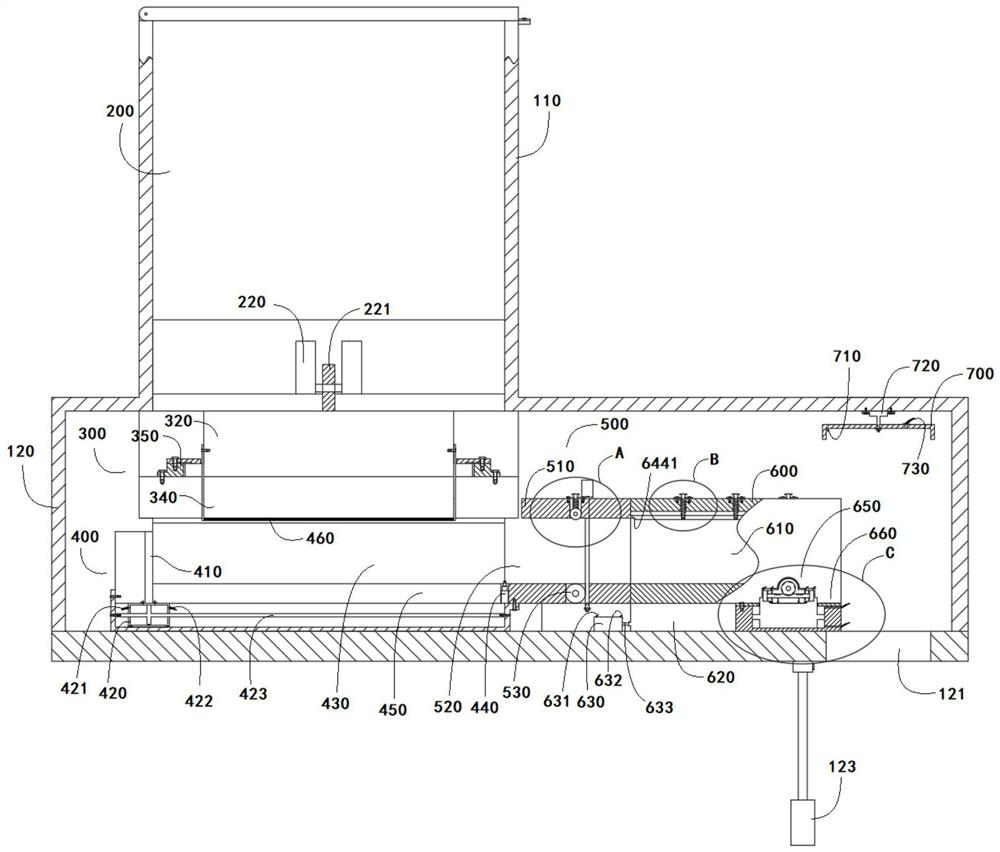

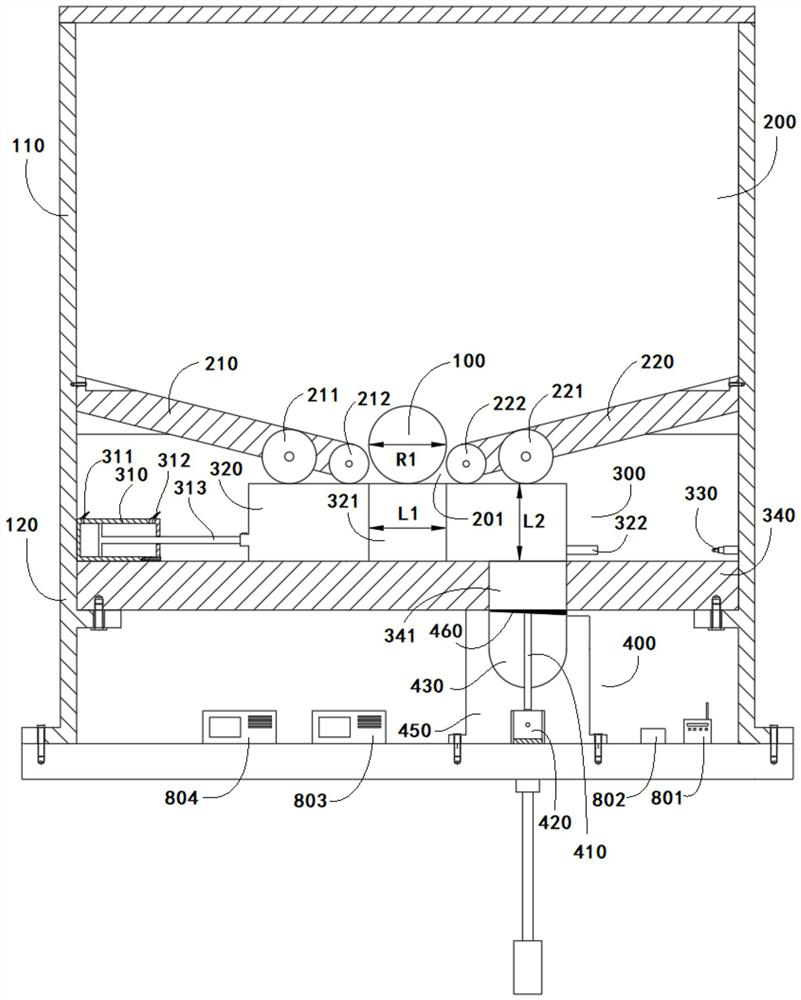

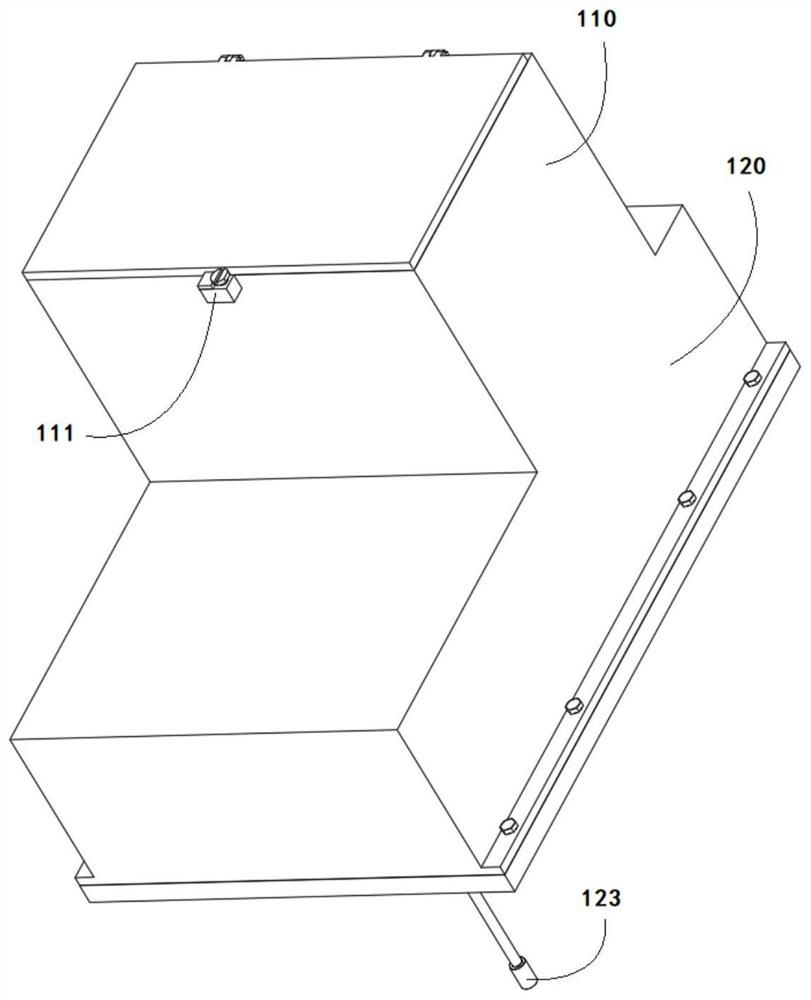

[0050] like Figure 1 ~ Figure 3As shown, this embodiment provides a system for adding metal rods for electroslag metallurgy. Taking the addition of aluminum rods with a circular cross section as an example, it is an aluminum casting machine, which includes a feeding unit, a cutting unit and a feeding unit. The feeding unit is arranged above the cutting unit, and the cutting unit is arranged at the feeding end of the feeding unit; it also includes a first bin body 110 and a second bin body 120, and the first bin body 110 is arranged above the second bin body 120 , the top of the first bin body 110 is also provided with an opening, the opening is provided with a sealing part, and a bin body switch 111 is arranged between the sealing part and the opening, by opening the bin body switch 111, metal bars can be put into the first bin body 110 100; the feeding unit is arranged in the first bin body 110, and the cutting unit and the feeding unit are both arranged in the second bin bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com