Beating and pressing plate structure, feeding mechanism and IC carrier plate processing equipment

A technology of plate structure and pressing plate, which is applied in the direction of metal processing equipment, welding equipment, welding equipment, etc., can solve the problems of inability to realize fully automatic marking work, complex and complicated equipment structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

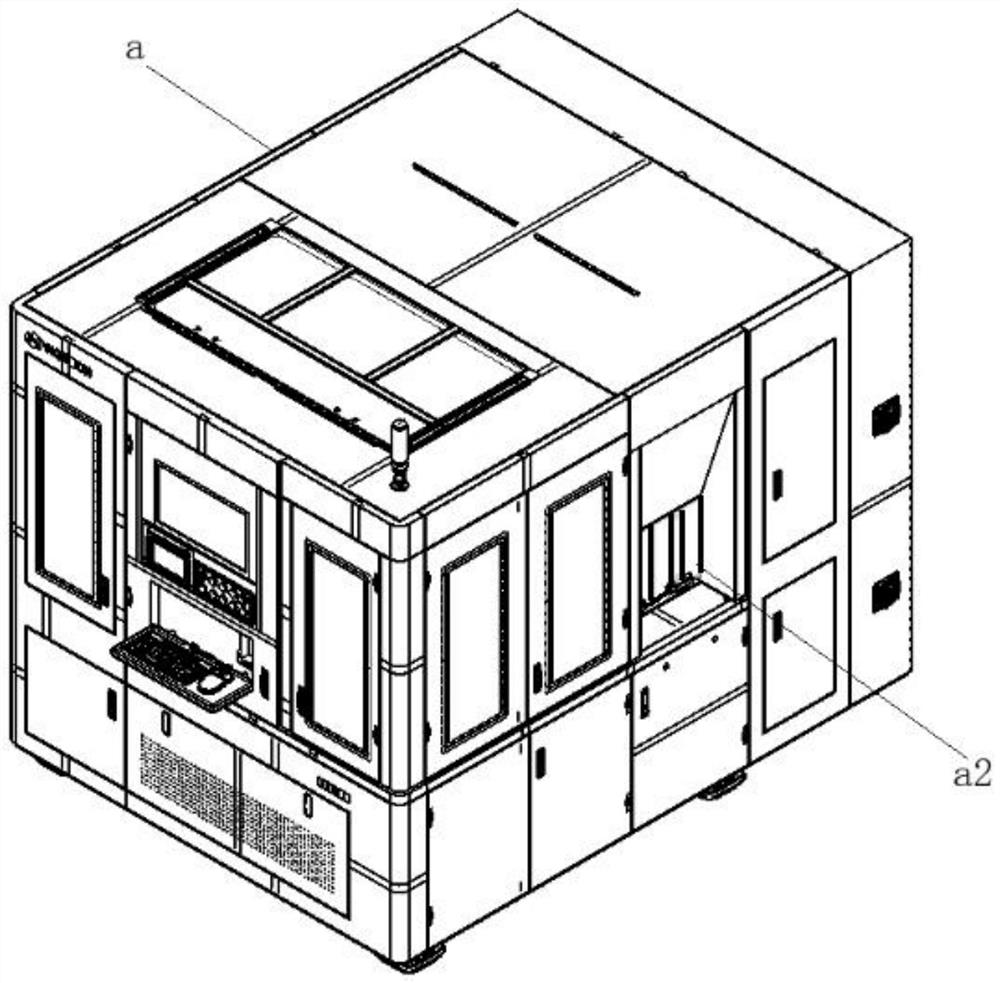

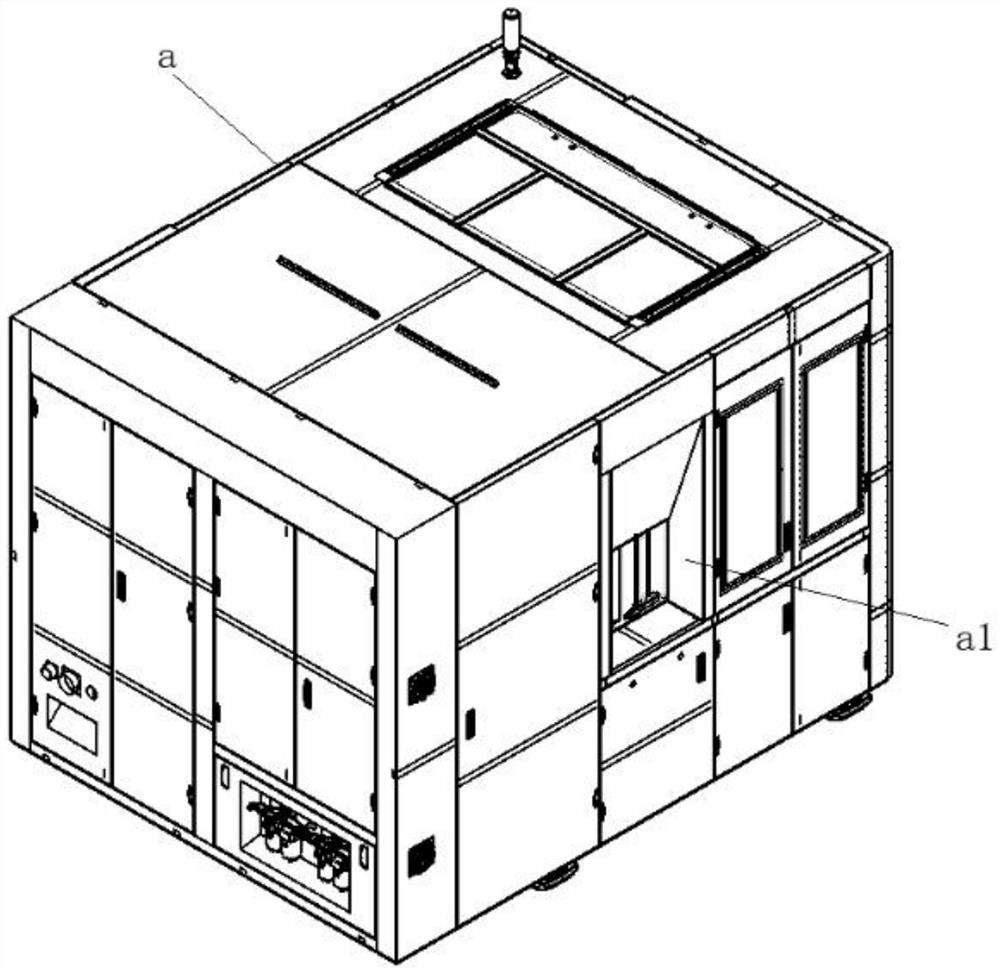

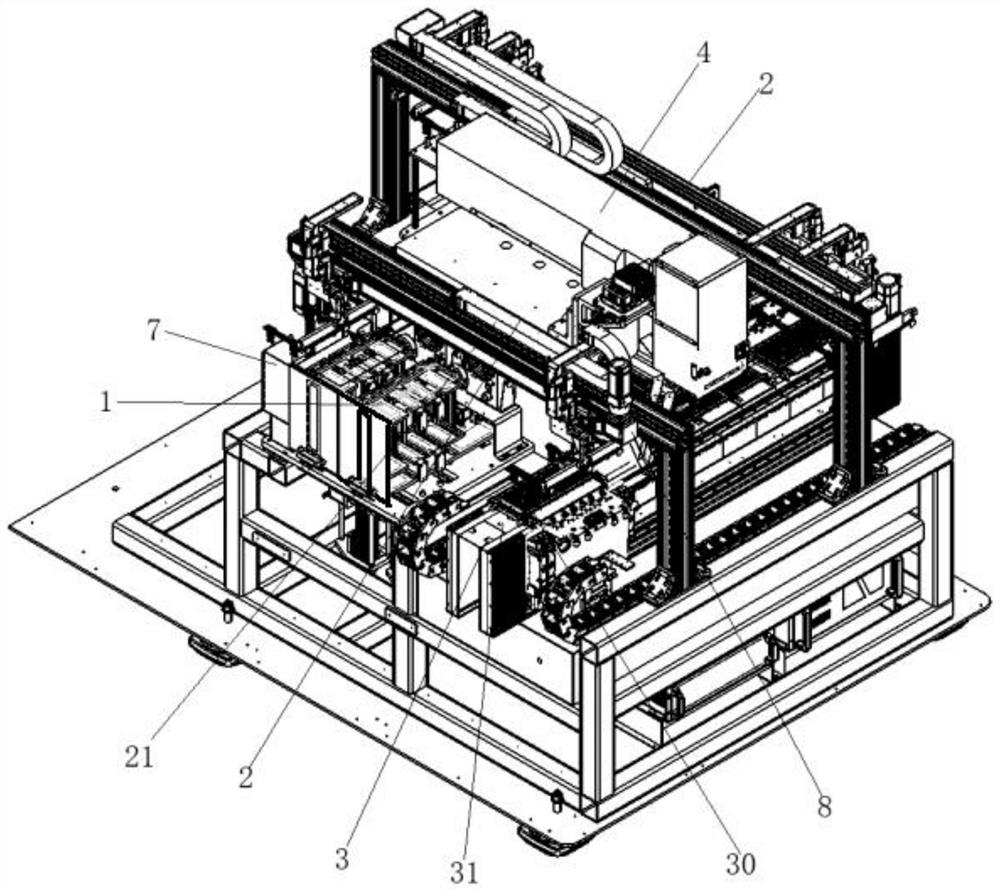

[0044] see Figure 1 to Figure 23 , The embodiment of the present invention provides an IC carrier board processing equipment, including a feeding bin 1, a reclaiming mechanism 2, a feeding mechanism 3, a marking system 4, a turning mechanism 5 and a feeding bin 6. The upper silo 1 is used to temporarily store IC carriers, and the reclaiming mechanism 2 is used to take out the IC carriers from the upper silo 1 and send the processed IC carriers to the lower silo 6 , the feeding mechanism 3 is used to send the IC carrier board taken out from the loading bin 1 by the reclaiming mechanism 2 to the marking system 4 for processing, and the marking system 4 is used for processing the IC The carrier board is processed, the turning mechanism 5 is used to turn the IC carrier board over and then send it to the marking system 4 for further processing, and the unloading bin 6 is used to temporarily store the processed IC carrier board. In this embodiment, feeding, feeding, identifying, m...

Embodiment 2

[0054] see Figure 3 to Figure 10 , the embodiment of the present invention provides an upper bin, including a carrier plate 17 for shelving stacked materials, a sensor 10 for sensing the height of the piled material, and a signal for driving the carrier plate according to the signal fed back by the sensor 10 17 a driving mechanism 11 for lifting, the driving mechanism 11 includes a driving shaft, the bearing plate 17 is arranged horizontally, the driving shaft is located below the bearing plate 17 and is arranged vertically to the bearing plate 17 . In this embodiment, the height of the stack can be sensed to automatically adjust the height of the carrying plate 17 to realize automatic feeding. Specifically, after multiple IC carriers are stacked in the loading bin, no matter how high the IC carriers are stacked, the IC carrier will be lifted to the highest position under the cooperation of the drive mechanism 11 and the sensor 10. , that is to ensure that the uppermost IC c...

Embodiment 3

[0061] see Figure 11 and Figure 12 , the embodiment of the present invention provides a material retrieving mechanism, including two columns 20 arranged oppositely and a beam 21 arranged between the two columns 20, the beam 21 is provided with a gripper assembly for grabbing materials 22. The gripper assembly 22 includes several gripping heads 23 capable of grabbing materials, several installation rods 24 for the grippers 23 to install, and a combination rod 25 for the installation rods 24 to install. The combination rods 25 There are a plurality of mounting positions for connecting the mounting rods 24 on the top, the distance between every two mounting positions can be adjusted, and each grabbing head 23 encloses a grabbing section for grabbing materials. In this embodiment, the beam 21 is supported by the column 20, so that the handle assembly 22 is suspended. When grasping, the gripper assembly 22 is driven to move downward to complete the grasping action. Specificall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com