Finishing machining method for peach-shaped groove of four-point contact ball bearing

A four-point contact, dressing and processing technology, applied in the field of bearing processing, can solve the problems of complex operation, single model, low precision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

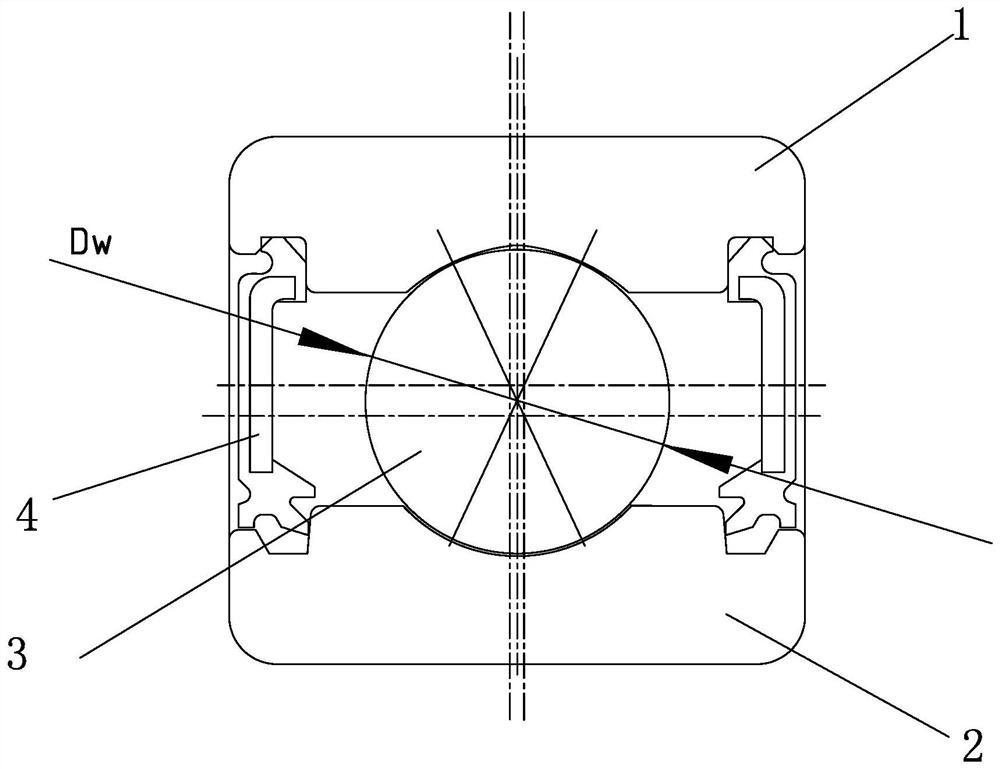

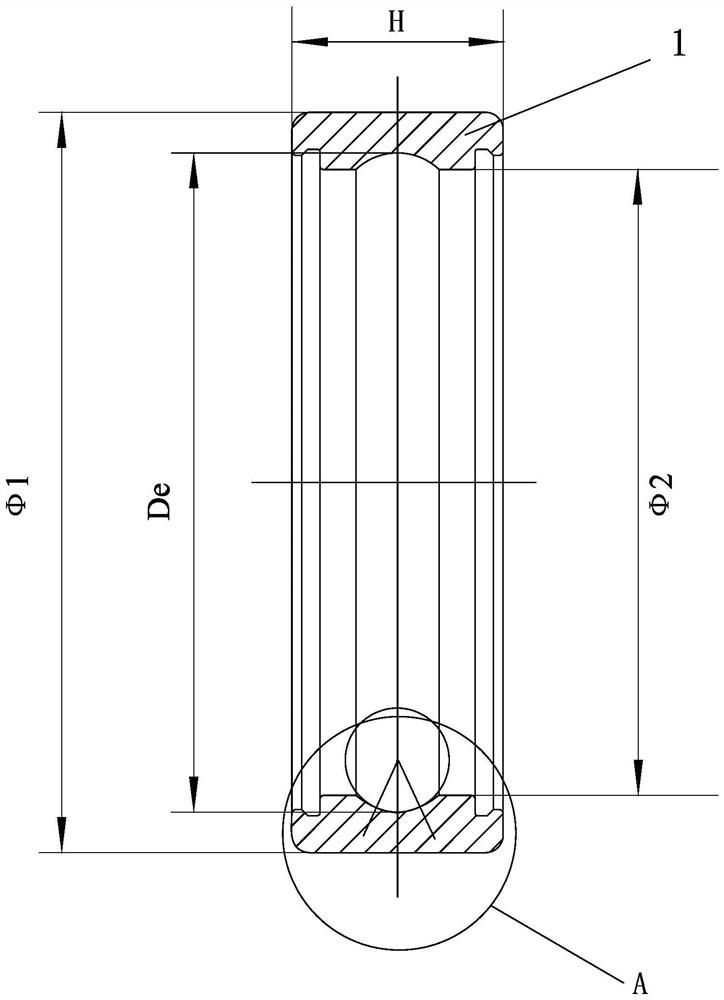

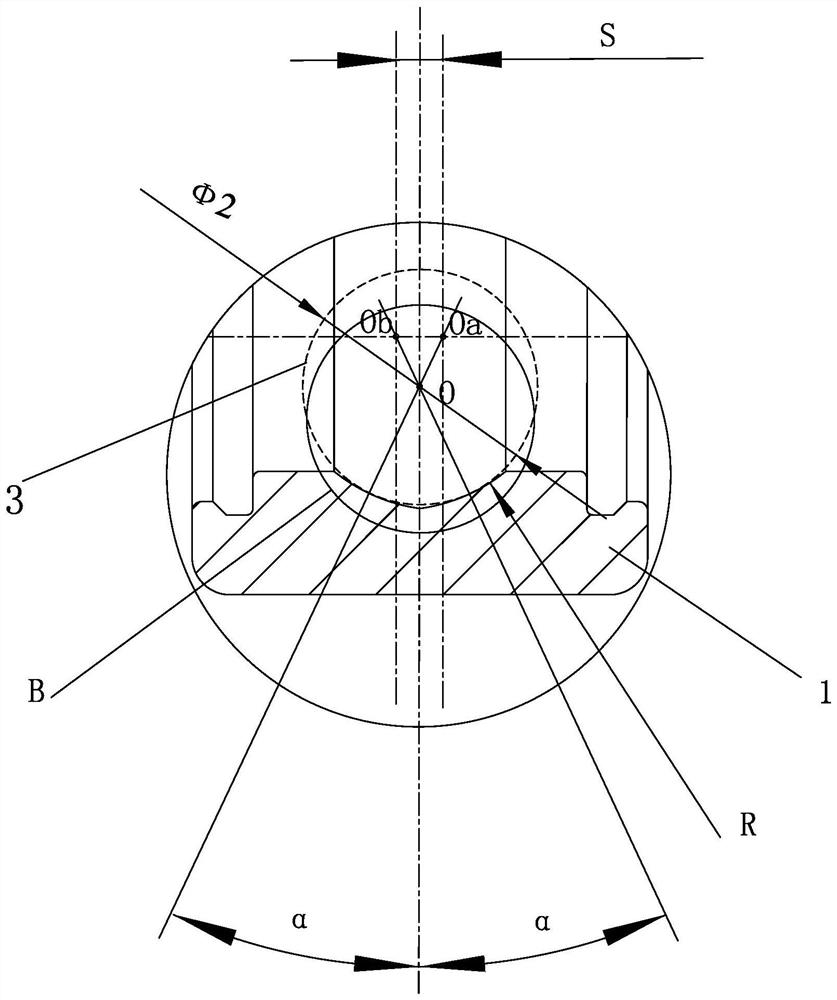

[0071] Such as Figure 1 to Figure 12 As shown, the four-point contact ball bearing peach-shaped groove trimming processing method, such as Figure 1 to Figure 4 As shown, the four-point contact ball bearing includes an outer ring 1, an inner ring 2 and several steel balls 3, and several steel balls 3 are evenly arranged and arranged in the channel formed by the outer ring 1 and the inner ring 2. Both ends of the contact ball bearing are provided with a sealing ring 4; the outer ring 1 is an integral structure, the channel of the outer ring 1 is a peach-shaped channel, the radius of curvature of the peach-shaped channel is R, and the steel ball 3 The contact angle α with the groove is 25°, the contact angle is the angle between the normal line of the contact point of the steel ball 3 and the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com