Intelligent material carrying robot

A technology for handling robots and intelligent materials. It is applied in the directions of manipulators, conveyor objects, transportation and packaging. It can solve the problems of poor mobility, limited working range, and low control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

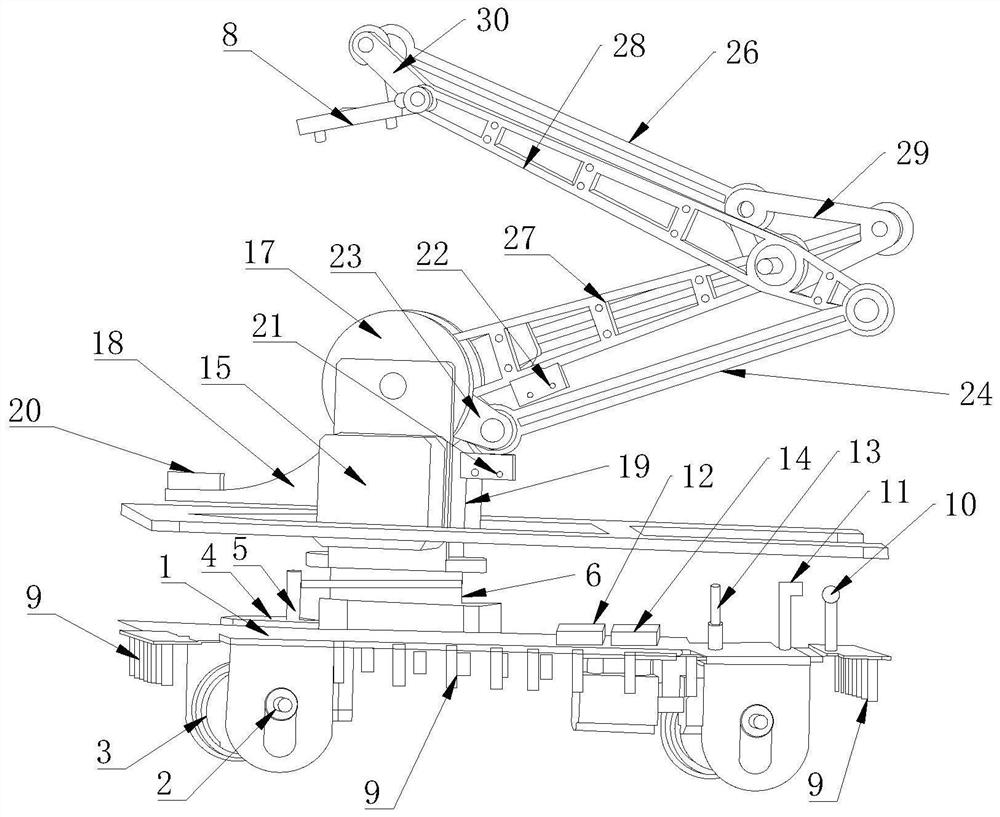

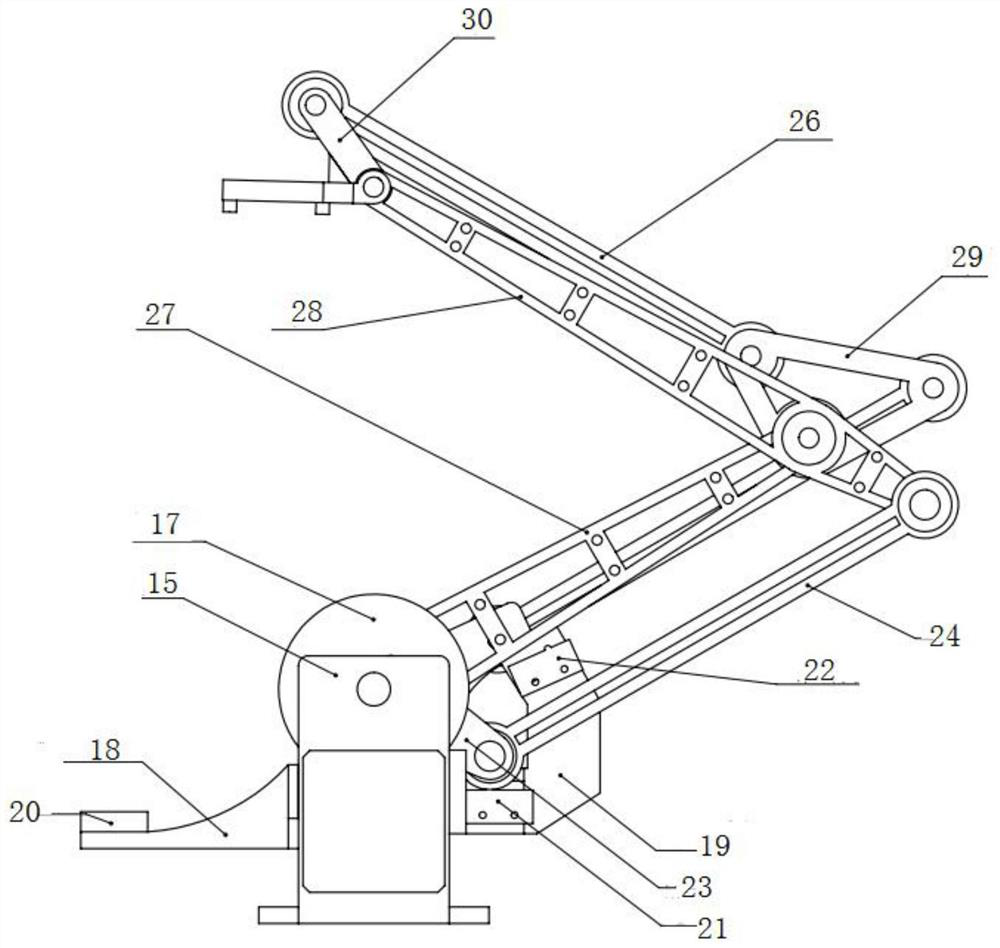

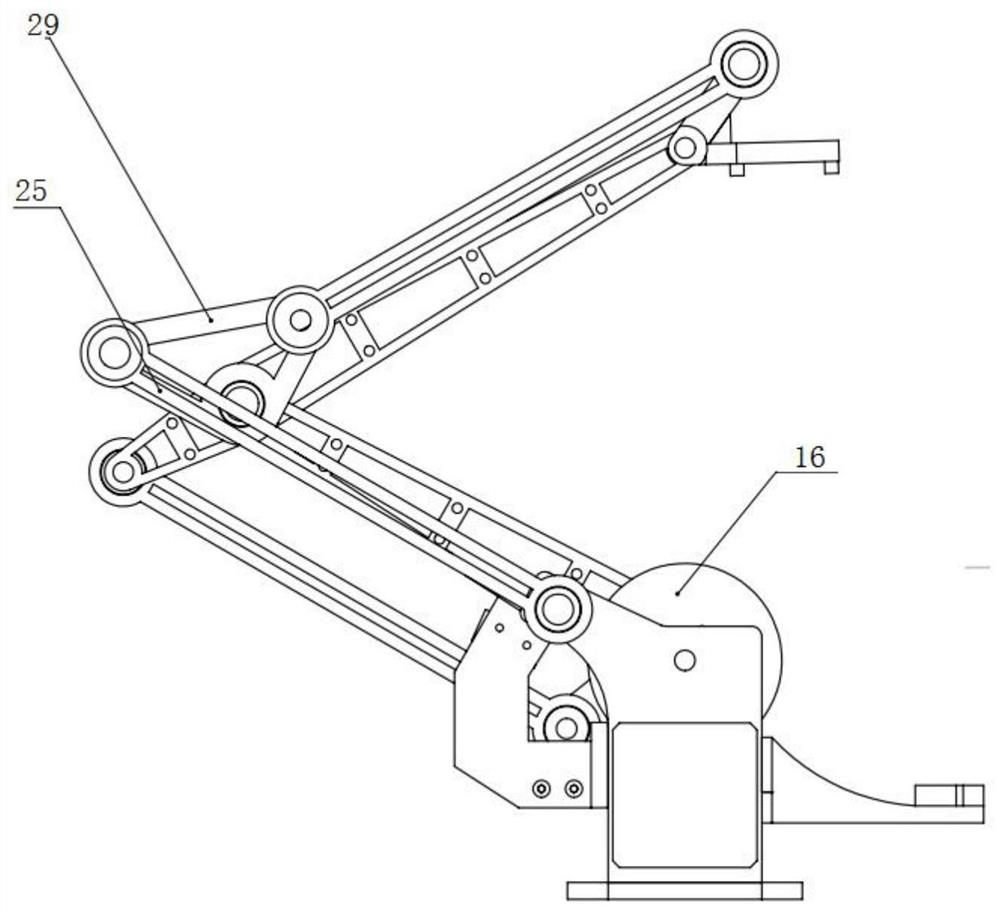

[0027] Embodiment: a kind of intelligent material handling robot, such as Figure 1 to Figure 5 As shown, it includes a chassis 1 and a driving device arranged at the bottom of the chassis 1, a steering gear is installed on the top of the chassis 1, and a mechanical arm mechanism is connected to the driving end of the steering gear. A stepper motor 7 for driving the mechanical arm mechanism is installed on the top of the chassis 1 . The free end of the mechanical arm mechanism is equipped with a V-shaped three-layer toothed mechanical claw 8 . Eight-way grayscale sensors 9 are installed on the front, rear, left and right sides of the chassis 1 . A two-dimensional code recognizer 10 and a color recognition sensor 11 are installed on the top of the chassis 1 . The top of the chassis 1 is equipped with a micro main controller 12, a WIFI signal receiver 13 and a battery 14 for the flight group.

[0028] In this embodiment, the chassis 1 is made of aluminum alloy, which has stro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com