Bamboo board for box body combination and manufacturing method thereof

A production method and technology of bamboo boards, which are applied in the direction of manufacturing tools, sustainable manufacturing/processing, containers, etc., can solve the problems of limited service life and low structural strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] As shown in the accompanying drawings: a kind of manufacture method for the bamboo board of cabinet assembly, comprises the following steps:

[0030] The first step is the pre-treatment of the bamboo chips, making the bamboo chips into sheets of uniform size, and the surface is deburred and polished;

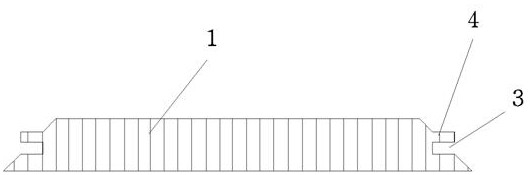

[0031] The second step is pressing and combining, including splicing in the direction of the length extension of the bamboo slices and pressing the two sides of the bamboo slices to form a bamboo plank after pressing;

[0032] The third step is to cut the bamboo board into the required size, take the thickness of the bamboo board as the width of the bamboo board, and take the length of the bamboo board as the width of the bamboo board;

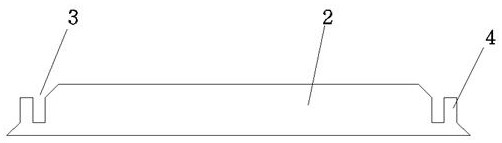

[0033] In the fourth step, the edge of the bamboo plank is provided with a groove 3 and a convex strip 4 perpendicular to the width direction of the bamboo plank and / or perpendicular to the length direction of the bamboo plank, the groove...

Embodiment 2

[0037] A bamboo board is made by the method of the above-mentioned embodiment. The structural strength and quality of the bamboo board are made by pressing a number of longitudinally arranged bamboo chips. The fiber texture of the bamboo board is smooth and clear, which effectively improves the quality of the bamboo board. It enhances the beauty of bamboo boards.

Embodiment 3

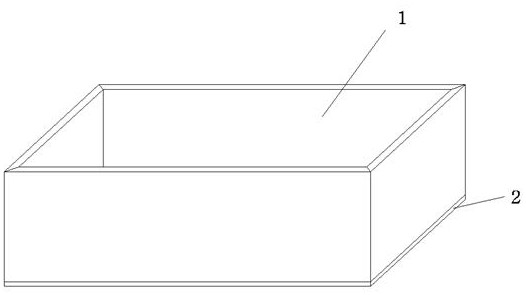

[0039] A box made of bamboo boards, which is combined with the bamboo boards in the second embodiment above, includes a bottom board 2 and four side boards 1, and the edges of the bottom board 2 are provided with grooves 3 parallel to the upper and lower surfaces of the bottom board 2 and raised Bar 4, the inclined surface is 45°, the side plate 1 is plugged on the edge of the bottom plate 2, the two ends of the side plate 1 are plugged in two, and the glue layer is applied at the joint to tightly bond. Preferably, bamboo nails or iron nails are used to strengthen the connection at the plug joint; after plugging, use a pressure of 2-10 MPa to press tightly until the glue layer is dry. It effectively improves the structural strength and sealing effect of the cabinet, and at the same time uses bamboo boards with clear texture and outstanding texture, which effectively improves the quality of the cabinet and is convenient for mass production.

[0040] This scheme arranges the bam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com