Construction method for precast beam body by adopting water-based release agent

A construction method and release agent technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of appearance quality defects, color difference of fair-faced concrete, etc., achieve shortened construction period, less residual release agent, and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

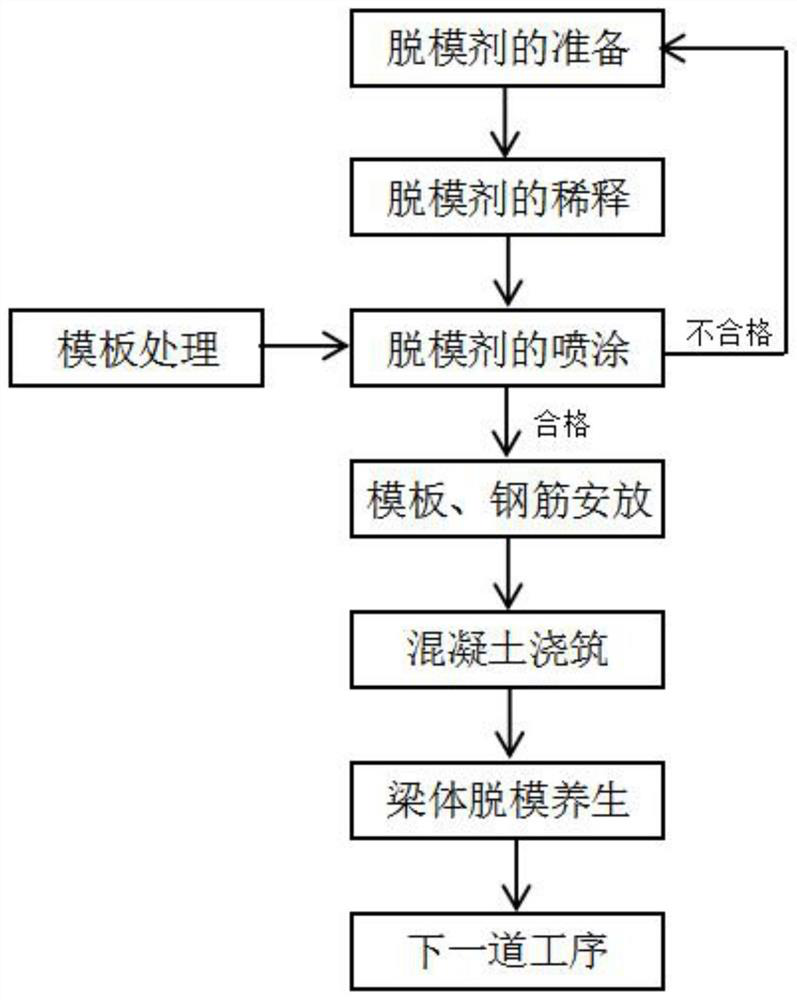

[0027] A prefabricated beam body using a water-based release agent construction method, such as figure 1 shown, including the following steps:

[0028] Step (1): Formwork treatment, using a secondary turnover steel formwork, first use an angle grinder to remove rust spots and residual concrete on the surface of the formwork, wipe it clean with a geotextile, and evenly spray a layer of concentrated release agent with a very thin thickness. Sprinkle a layer of fly ash after the film is formed, polish the surface of the template again and wipe it clean with a geotextile to completely remove the rust spots and stains on the surface of the template;

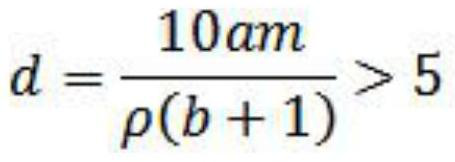

[0029] Step (2): Dilute the water-based release agent to ensure that the oil film thickness required for concrete demoulding is calculated in 5 μm. The water-based release agent with the following characteristic values is used: the solid content is 50%, and the amount used on the template per unit area is 0.05kg / m 2 , the density...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com