High-strength LTCC glass ceramic material and preparation method thereof

A glass-ceramic, high-strength technology, applied in the field of electronic components and ceramic materials for microwave electronic components, can solve the problem of low strength of glass-ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

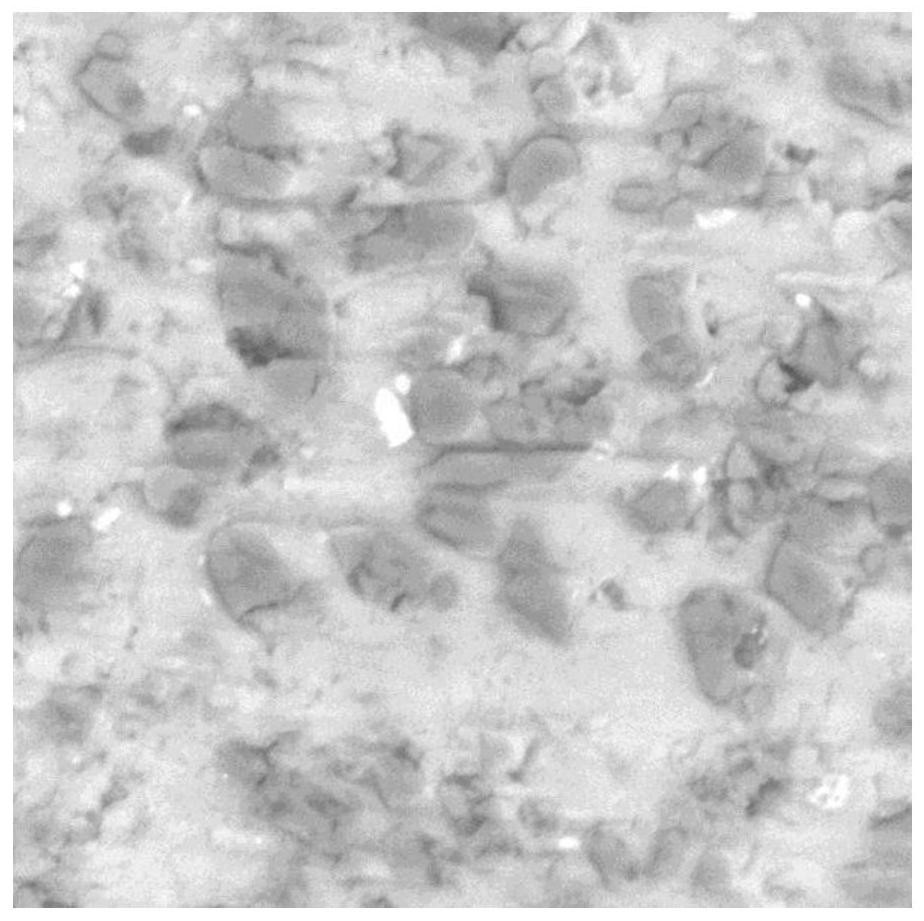

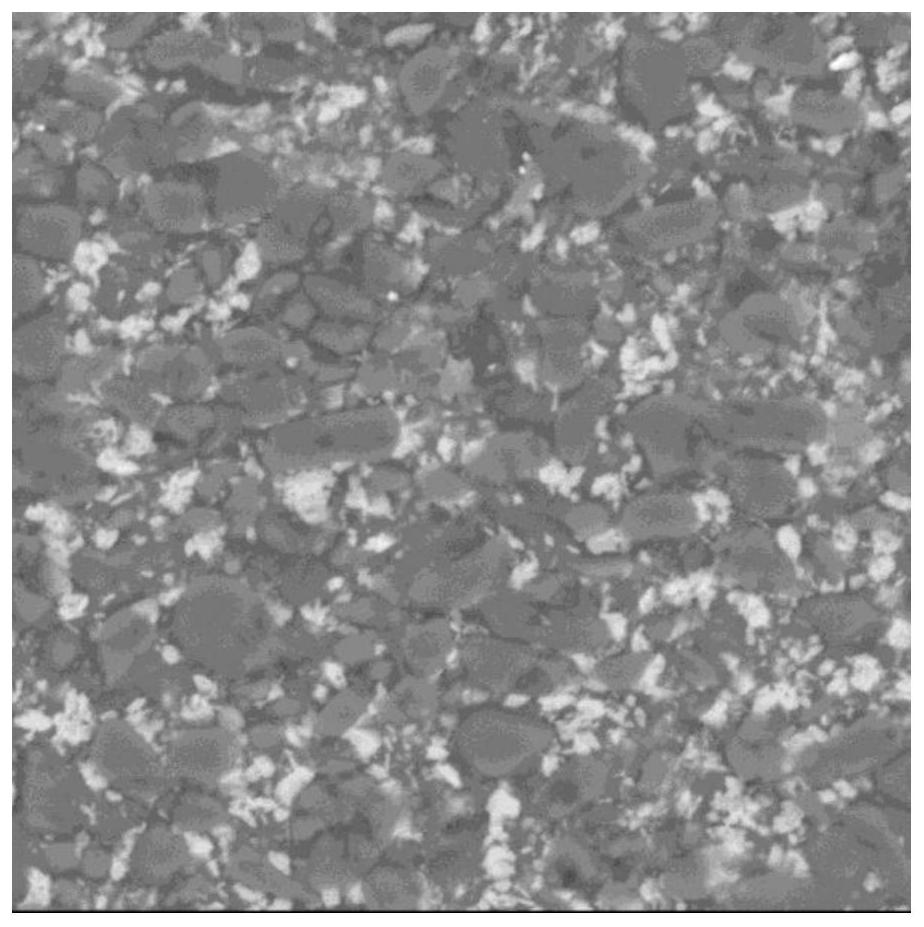

Image

Examples

Embodiment Construction

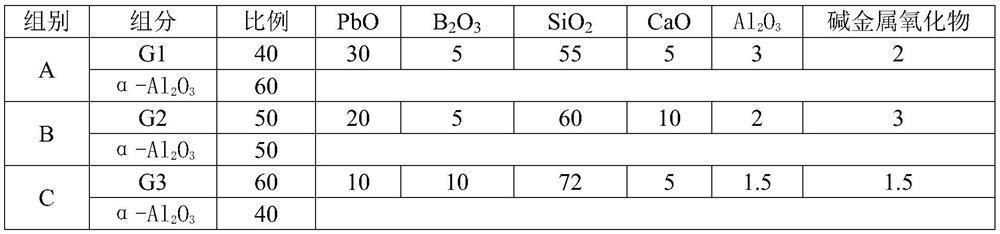

[0022] A kind of glass formula of high-strength LTCC ceramic material, by mass percentage (wt%), as shown in table 1:

[0023] Table 1 Glass formulation of a high-strength LTCC ceramic material

[0024]

[0025] In Table 1, G1, G2, and G3 represent lead borosilicate glass series.

[0026] The main process parameters are as follows:

[0027] Glass smelting: lead borosilicate glass at 1400℃, smelting for 2h.

[0028] Sintering process: 850°C, 10min.

[0029] Sintering shrinkage: Group A is 12% to 13%; Group B is 12% to 14%; Group C is 13% to 15%. The electrical performance test data after sintering are shown in Table 2.

[0030] Table 2 Comparison table of electrical performance test data of each group after sintering at 850°C for 10 minutes

[0031]

[0032] Bending strength: as shown in Table 3.

[0033] Table 3 Comparison table of flexural strength test data of each group after sintering at 850°C for 10 minutes

[0034] group A B C Bending stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com