Formula and method for producing ceramsite by taking waste incineration fly ash as main body

A waste incineration fly ash and waste fly ash technology, which is applied in the production of ceramic materials, ceramic products, applications, etc., can solve the problems of complex process, high investment and operation costs, and limited popularization and promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

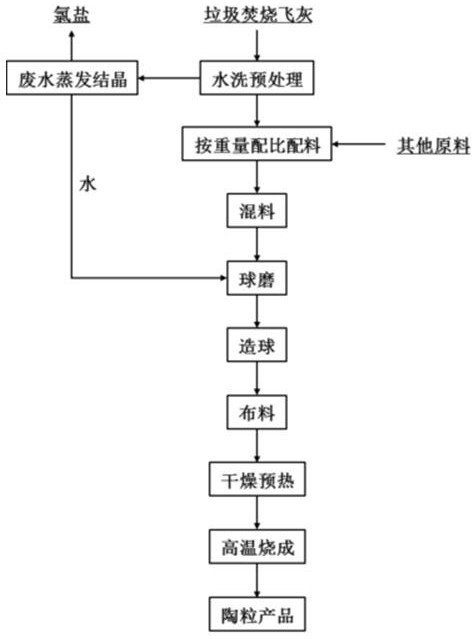

[0039] The composition of raw materials in this example is by weight: 25 parts of garbage fly ash, 40 parts of fly ash, 20 parts of low-quality kaolin, 5 parts of foaming agent, and 10 parts of combustion aid. Foaming agent is CaCO 3 , the combustion aid is CaO, and the specific process is as follows:

[0040] The first step, fly ash pretreatment

[0041] First, the fly ash is pretreated by water washing to fully dissolve the chlorine-containing compounds in the fly ash.

[0042] S1. According to the ratio of garbage fly ash to water 1:0.8, add water for full mixing, and stir evenly to speed up the dissolution efficiency, so as to achieve full leaching of chloride ions in fly ash.

[0043] S2. Separating the fly ash treated in step S1 from solid to liquid, using a filter press to make the water content in the fly ash filter residue within 10-20%, and transferring it to the mud bin for storage; In the example, a chemical precipitant is added to the filtrate, and then it is a...

Embodiment 2

[0055] The raw material in the present embodiment is composed of: 30 parts of garbage fly, 35 parts of fly ash, 20 parts of inferior kaolin, 5 parts of foaming agent, and 10 parts of combustion aid. Foaming agent is CaCO 3 , the combustion aid is CaO, and the specific process is as follows:

[0056] The first step, fly ash pretreatment

[0057] First, the fly ash is pretreated by water washing to fully dissolve the chlorine-containing compounds in the fly ash.

[0058] S1. According to the ratio of garbage fly ash to water 1:0.8, add water for full mixing, and stir evenly to speed up the dissolution efficiency, so as to achieve full leaching of chloride ions in fly ash.

[0059] S2. Separating the fly ash treated in step S1 from solid to liquid, using a filter press to make the water content in the fly ash filter residue within 10-20%, and transferring it to the mud bin for storage; In the example, a chemical precipitant is added to the filtrate, and then it is allowed to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com