Prestressed fabricated pavement structure and construction method

A prefabricated and prestressed technology, applied to pavements, roads, roads and other directions paved with prefabricated blocks, can solve the problems of difficult replacement, high cost and low pavement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

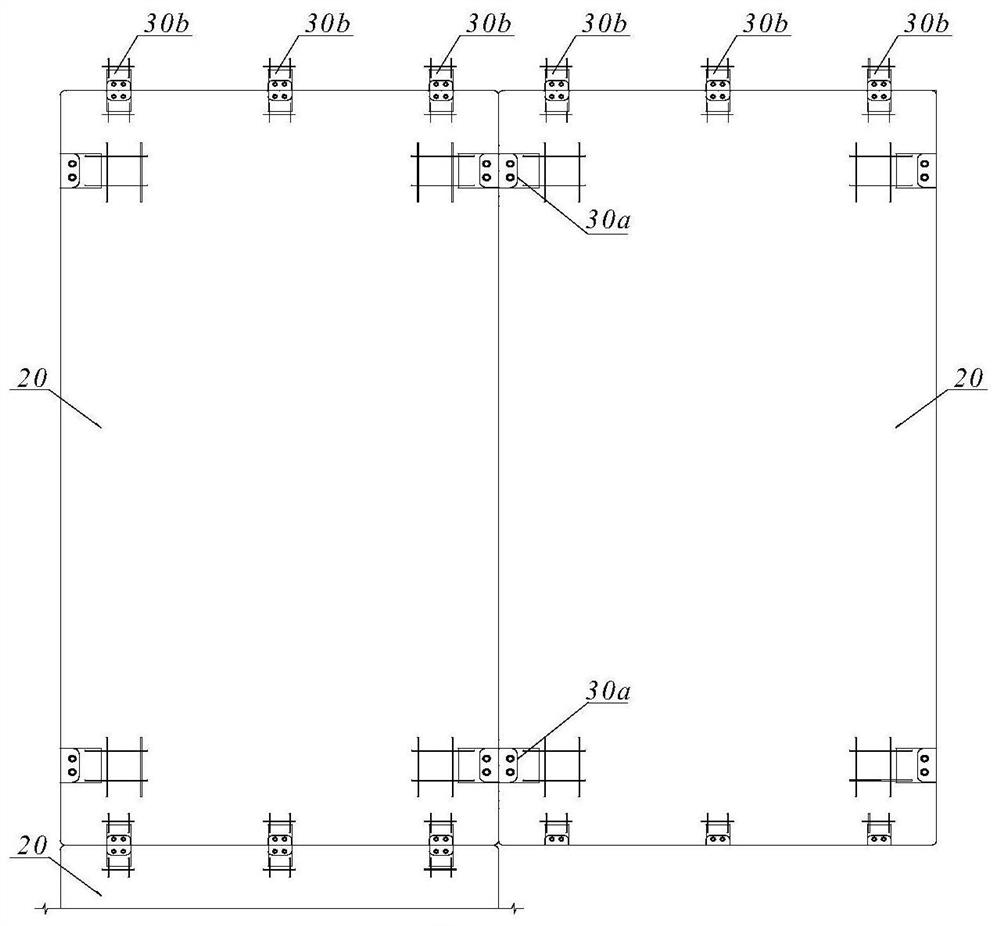

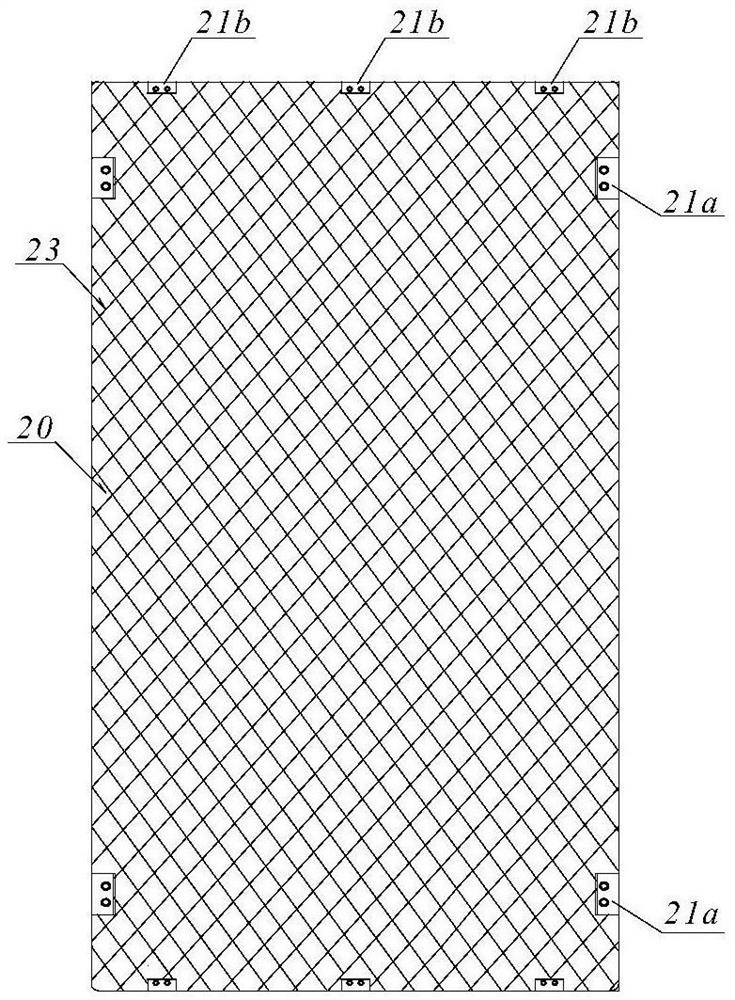

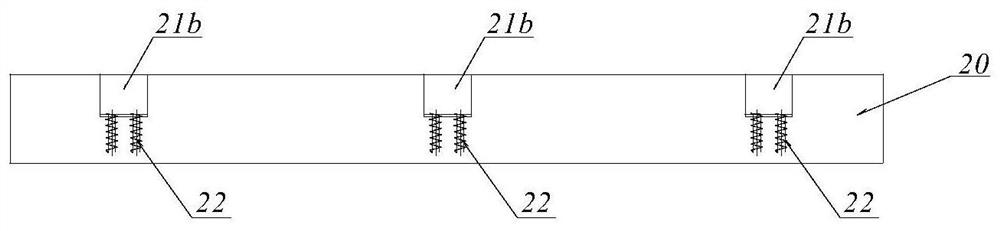

[0055] refer to figure 1 and Figure 15 , a prestressed assembled pavement structure of the present invention, the prefabricated pavement panel 20 is paved on the under-slab foundation to form an assembled pavement. The prefabricated path panel 20 adopts a unidirectional prestressed reinforced concrete structure, and each prefabricated path panel 20 is provided with longitudinal U-shaped grooves 21a at intervals along the width direction at the two transverse connection ends, and transverse U-shaped grooves 21a are arranged at intervals along the width direction at the two longitudinal connection ends. Groove 21b, longitudinal U-shaped groove 21a and transverse U-shaped groove 21b are recessed from the top surface of prefabricated path panel 20, and two adjacent prefabricated path panels 20 are formed in the corresponding transverse U-shaped groove 21a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com