Fly ash air-cooling drying system and process

A technology of air-cooled drying and circulating air system, which is used in drying solid materials, drying cargo handling, drying gas layout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

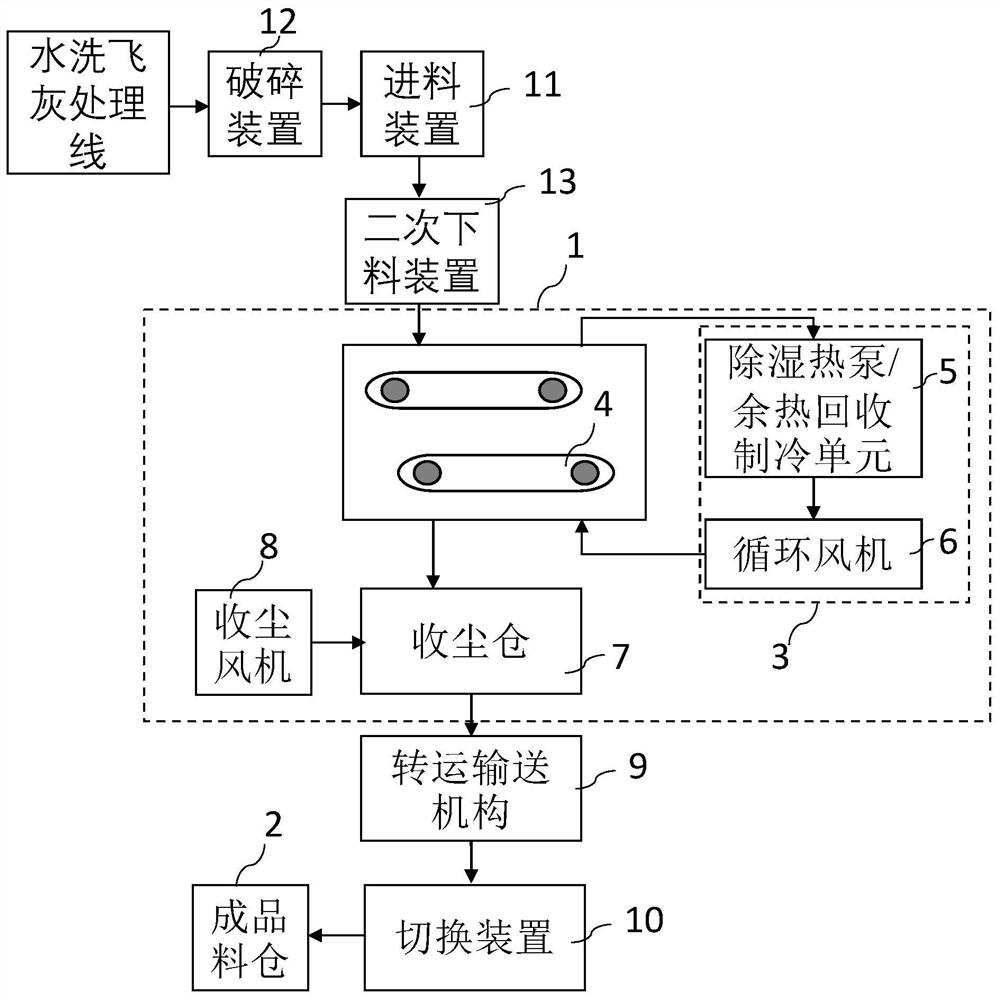

[0052] The material in this example is the washed fly ash from the washed fly ash processing line, and its water content is 40%. The above-mentioned fly ash air-cooled drying system is used for treatment. First, the washed fly ash is crushed. , enters the air-cooled circulation drying device after passing through the feeding device and the secondary feeding device, and performs drying treatment under the action of circulating air at a temperature of 68°C. The mixed gas after drying treatment enters the circulating air system and is dehumidified by a heat pump / The waste heat recovery unit cools down and dehumidifies the mixed gas, and heats the circulating air at the same time to form a humidity difference of the circulating air, and re-participates in the drying process from the bottom of the air-cooled circulating drying device (bottom of the material) through the circulating fan; completes the drying process The finished material is transferred to the finished product silo ...

Embodiment 2

[0054] The material in this example is the washed fly ash from the washed fly ash processing line, and its water content is 50%. The above-mentioned fly ash air-cooled drying system is used for treatment. First, the washed fly ash is crushed. , enter the air-cooled circulating drying device after passing through the feeding device and the secondary feeding device, and perform drying treatment under the action of circulating air at a temperature of 65°C. After drying, the mixed gas enters the circulating air system, and uses a dehumidification heat pump / The waste heat recovery unit cools down and dehumidifies the mixed gas, and heats the circulating air at the same time to form a humidity difference of the circulating air, and re-participates in the drying process from the bottom of the air-cooled circulating drying device (bottom of the material) through the circulating fan; completes the drying process The finished material is transferred to the finished product silo through...

Embodiment 3

[0056] The material in this example is the washed fly ash from the washed fly ash processing line, and its water content is 55%. The above-mentioned fly ash air-cooled drying system is used for treatment. Firstly, the washed fly ash is crushed. , enters the air-cooled circulation drying device after passing through the feeding device and the secondary feeding device, and performs drying treatment under the action of circulating air at a temperature of 50°C. The mixed gas after drying treatment enters the circulating air system and is dehumidified by a heat pump / The waste heat recovery unit cools down and dehumidifies the mixed gas, and heats the circulating air at the same time to form a humidity difference of the circulating air, and re-participates in the drying process from the bottom of the air-cooled circulating drying device (bottom of the material) through the circulating fan; completes the drying process The finished material is transferred to the finished product sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com