Packaging product and production method thereof

A product and packaging area technology, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., which can solve problems such as increased processing costs and decreased profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

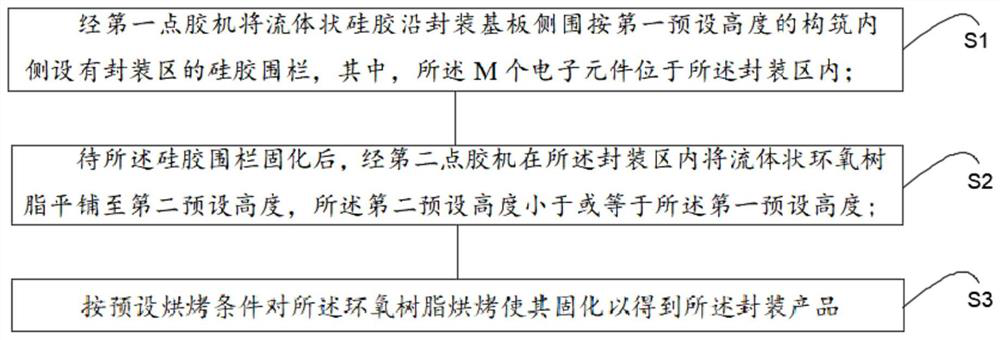

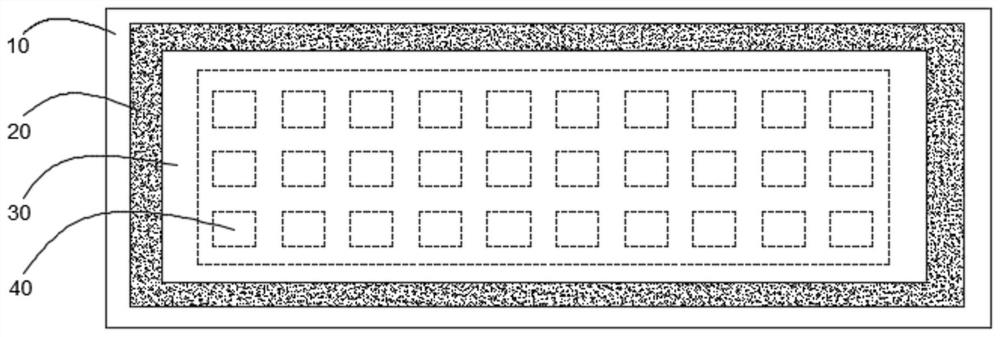

[0023] refer to figure 1 , showing a flow chart of the steps of a method for preparing a packaged product, which is used to package electronic components arranged on the surface of a package substrate, the electronic components are provided with M, and M is an integer greater than or equal to 1, and the method includes the following step,

[0024] S1, using the first dispensing machine to enclose the fluid silicone along the side of the packaging substrate according to the first preset height to build a silicone fence with a packaging area on the inside, wherein M electronic components are located in the packaging area;

[0025] S2, after the silicone fence is cured, spread the fluid epoxy resin to a second preset height in the packaging area via a second glue dispenser, and the second preset height is less than or equal to the first preset height a preset height;

[0026] S3, curing the epoxy resin according to preset baking conditions to obtain the packaging product.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Surface dry time | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com