A magnetic-gravity-magnetic combined beneficiation process for processing lean magnetite

A technology of lean magnetite and process, applied in the field of magnetic-gravity-magnetic combined beneficiation process, can solve the problems affecting the second-stage grinding processing capacity, energy waste, increase grinding cost, etc., so as to reduce grinding cost and production The effect of cost, energy saving and consumption reduction is remarkable, and the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

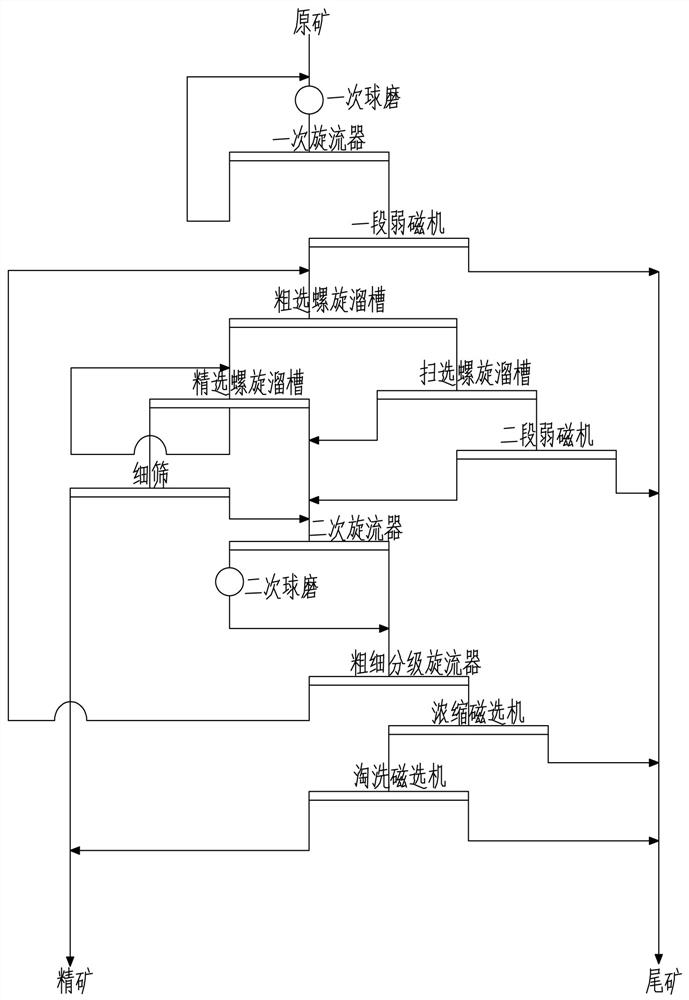

[0032] The heavy-magnetic sieve combination operation is composed of a spiral chute, a fine screen and a two-stage magnetic weakening machine, wherein the re-selection process composed of the spiral chute is a re-selection process of coarse, fine, and sweep;

[0033] The first section of weak magnetic concentrate is fed into the roughing spiral chute for separation to obtain coarse snail concentrate and coarse snail tailings; the coarse snail tailings are fed into the sweeping spiral chute for separation to obtain the sweeping snail concentrate and sweeping snail tailings Sweeping snail tailings are fed into the second-stage weak magnetic machine to obtain the second-stage weak magnetic concentrate and the second-stage weak magnetic tailings, and the second-stage weak magnetic tailings are discarded; the coarse snail concentrate is fed into the selected spiral chute to obtain Fine snail middle ore, fine snail concentrate and fine snail tailings; the fine snail middle ore is sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com