Bottle cap gasket adding machine

A bottle cap and pad machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

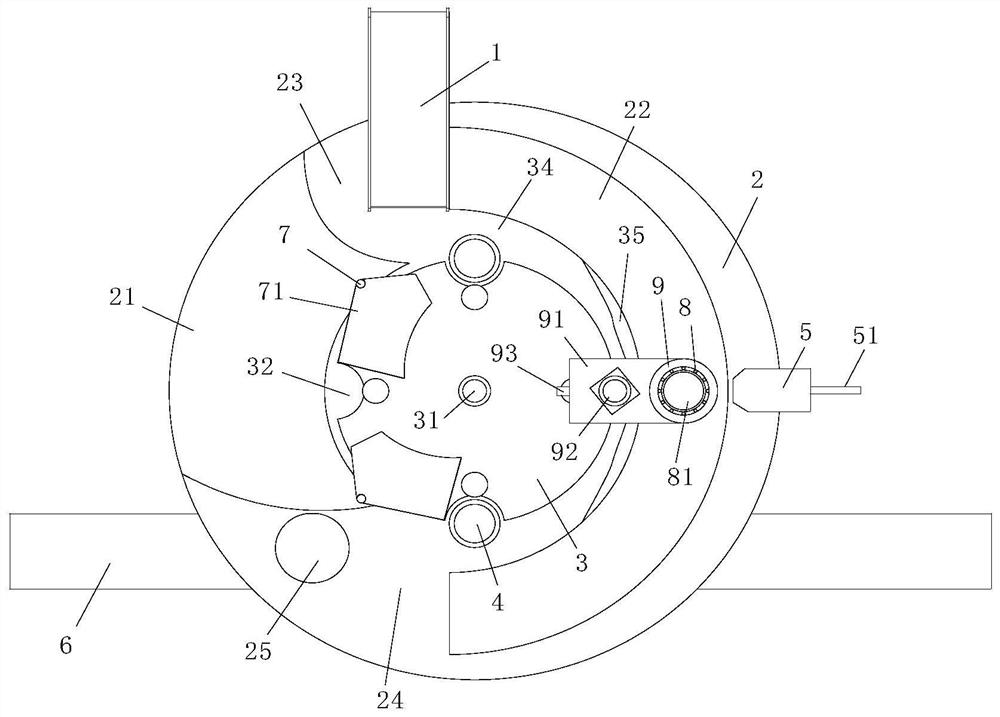

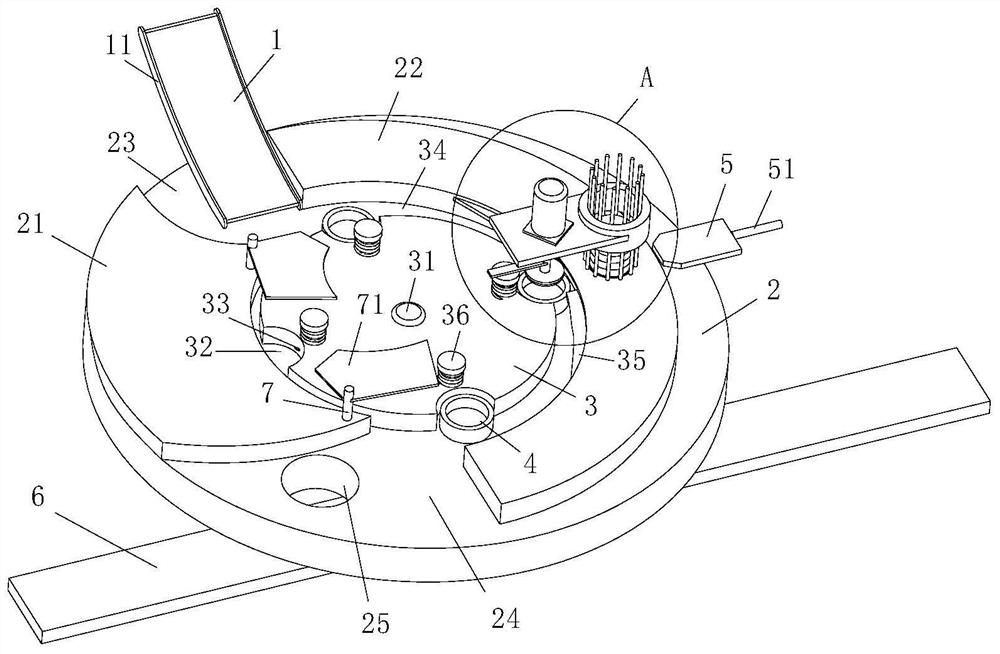

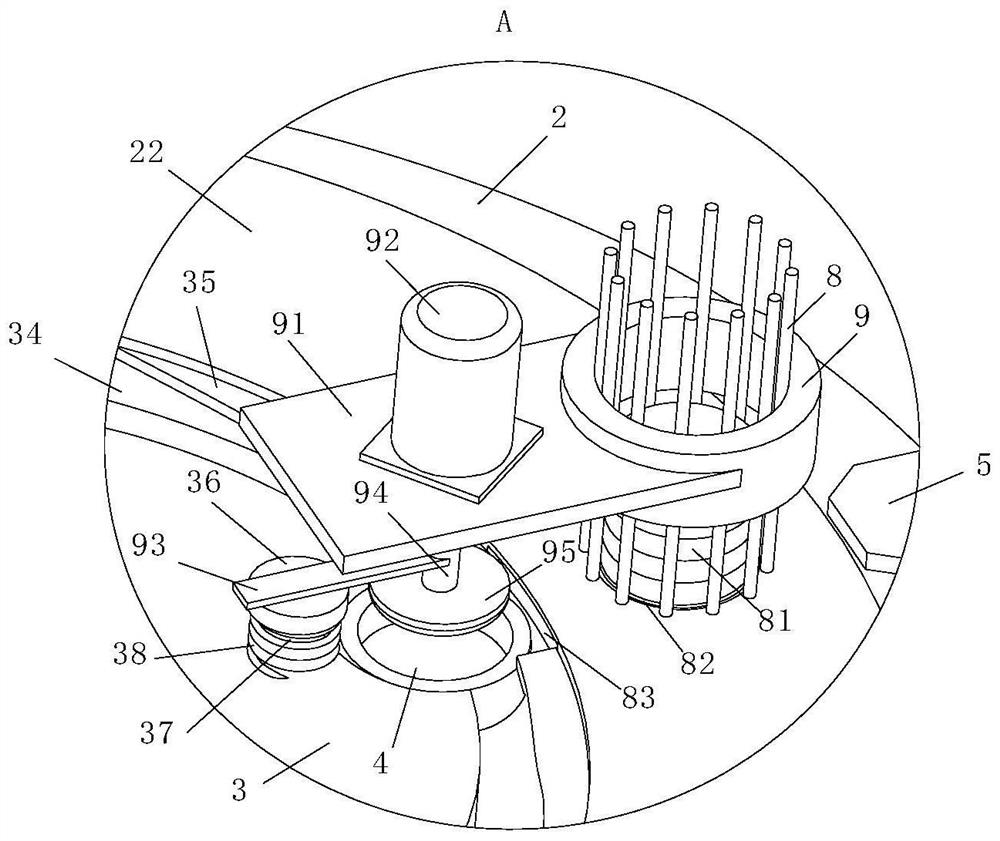

[0032] As an embodiment of the present invention, the inner side surface of the second arc-shaped protrusion 22 and the outer side surface of the disc are eccentrically arranged, and the width of the monolithic channel 34 gradually increases from the press-in station to both sides. , the bottle cap 4 collides with the inner side surface of the semicircular carrying notch 32 and the inner side surface of the second arc-shaped protrusion 22 at the same time when it is pressed into the station. By setting the eccentric arrangement between the inner side surface of the second arc-shaped protrusion 22 and the outer side surface of the disc, the bottle cap 4 can have a larger space to move at the feeding port 23 and the discharging port 24, which is convenient for the bottle cap. 4. The smooth feeding or smooth discharging can also make the bottle cap 4 be pressed when it is pressed into the station, so as to achieve precise positioning and avoid the misalignment of the gasket 81 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com