Bottom-cleaning-free self-moving roof protection system for return airway of fully mechanized coal mining face of thin coal seam of coal mine

A technology for fully mechanized mining face and thin coal seam, which is applied to mine roof supports, mining equipment, earth-moving drilling, etc., and can solve the problems of unsteady drawworks, poor safety, and small adjustment height range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

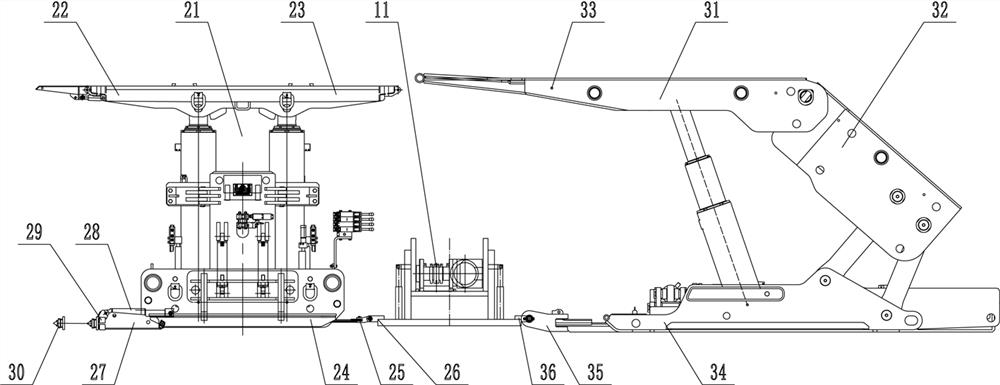

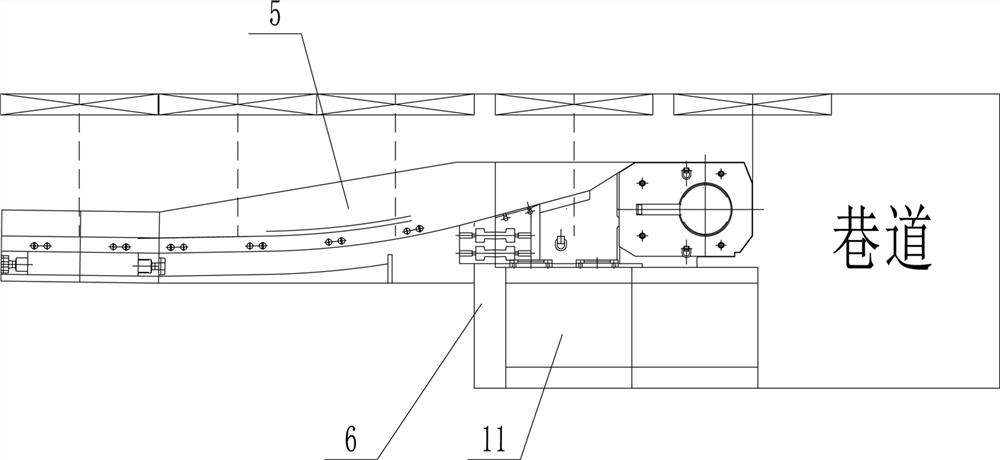

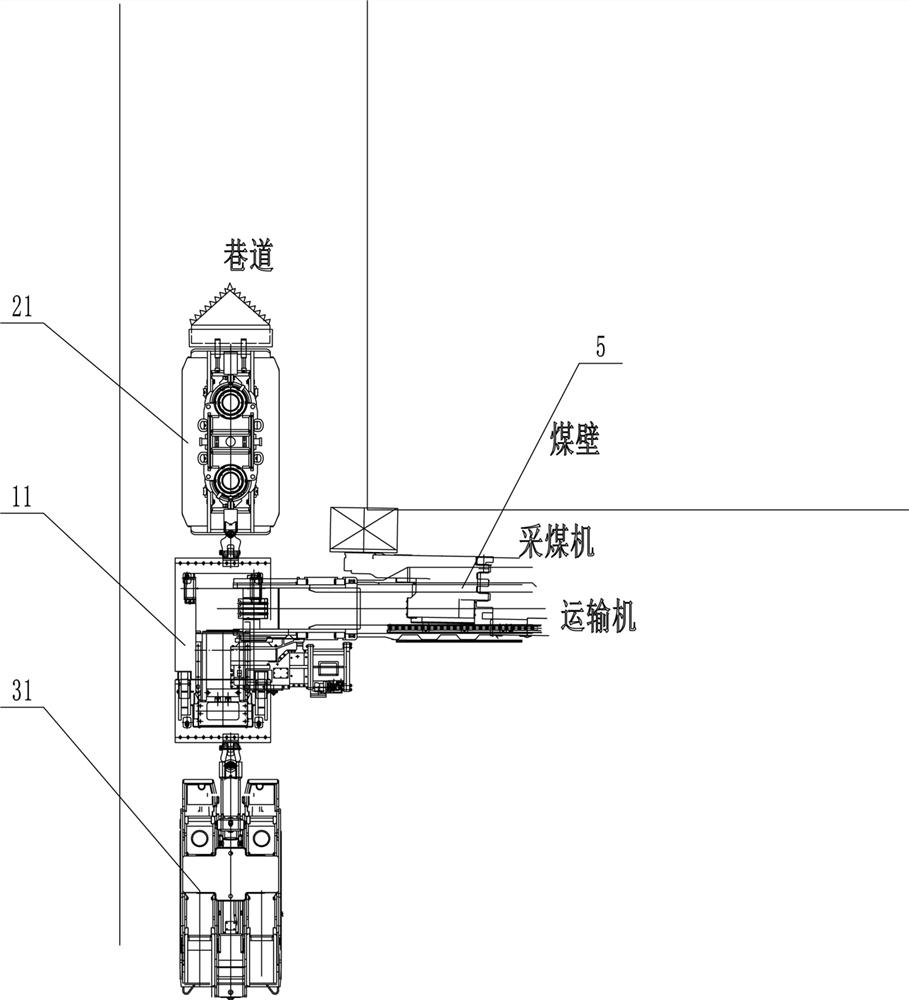

[0039] Such as Figure 1-Figure 8 As shown, a bottom-clearing self-moving roof protection system for the return airway of the fully mechanized coal mining face in a coal mine, including the tail support pad part 11 of the conveyor, the front roadway roof support part 21 and the rear roadway support Section 31.

[0040] The support pad frame part of the tail of the transporter includes a base plate 1, four telescopic jacks 2, two guide plates 3, a support platform 4 and a hydraulic system, and the two guide plates 3 are vertically fixed on the base plate 1, Two guide plates 3 are arranged in parallel, and vertical guide holes 5 are respectively arranged on the two guide plates 3 .

[0041] The support platform 4 is a trough-shaped platform, the two vertical sides 4-1 of the trough-shaped platform are parallel and arranged close to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com