Rolling bearing with high-temperature warning function

A rolling bearing, high temperature technology, applied in the direction of rolling contact bearings, rotating bearings, bearings, etc., can solve the problems of oil film thinning, bearing scrapping, unfavorable bearing loads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

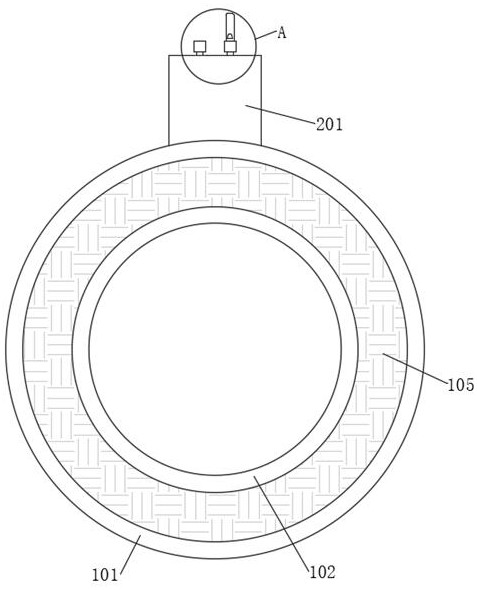

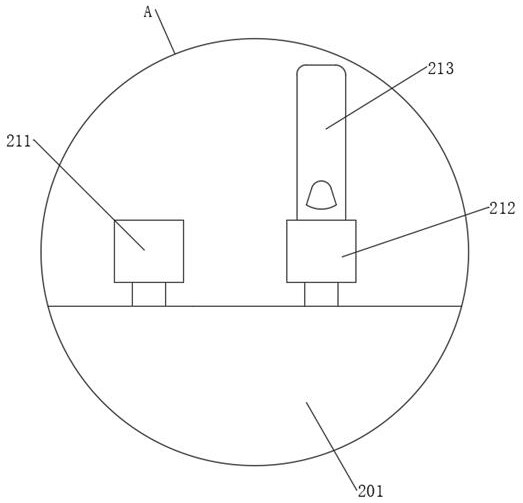

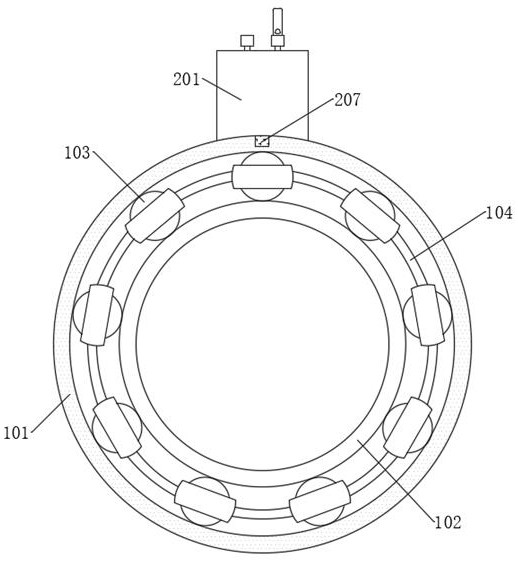

[0045] see Figure 1-11 , a rolling bearing with a high temperature warning function, comprising a bearing outer ring 101, a bearing inner ring 102, rolling elements 103, a cage 104, and a sealant cover 105, a support box 201 is fixedly connected to the outer wall of the bearing outer ring 101, and the support box Two police driving splints 202 are arranged symmetrically in the 201, and an elastic pull rope 203 is connected between the two police driving splints 202, and an elastic storage balloon 204 and an elastic inflatable balloon are arranged between the two elastic pull ropes 203. 205, the elastic inflatable balloon 205 and the elastic storage balloon 204 are located on the upper and lower sides of the elastic drawstring 203 respectively, and the elastic storage balloon 204 is filled with a solid high-temperature sensing ball 206, and the high-temperature sensing ball 206 is made of thermoplastic resin material The outer wall of the bearing inner ring 102 is embedded wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com