Aerodynamic heat full-field measurement system and method based on embedded temperature-sensitive paint

A measurement system and embedded technology, applied in the field of temperature-sensitive paint measurement, can solve problems such as limiting the application of temperature-sensitive paint measurement technology, carbonization of temperature-sensitive paint coating, and temperature rise of the model surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

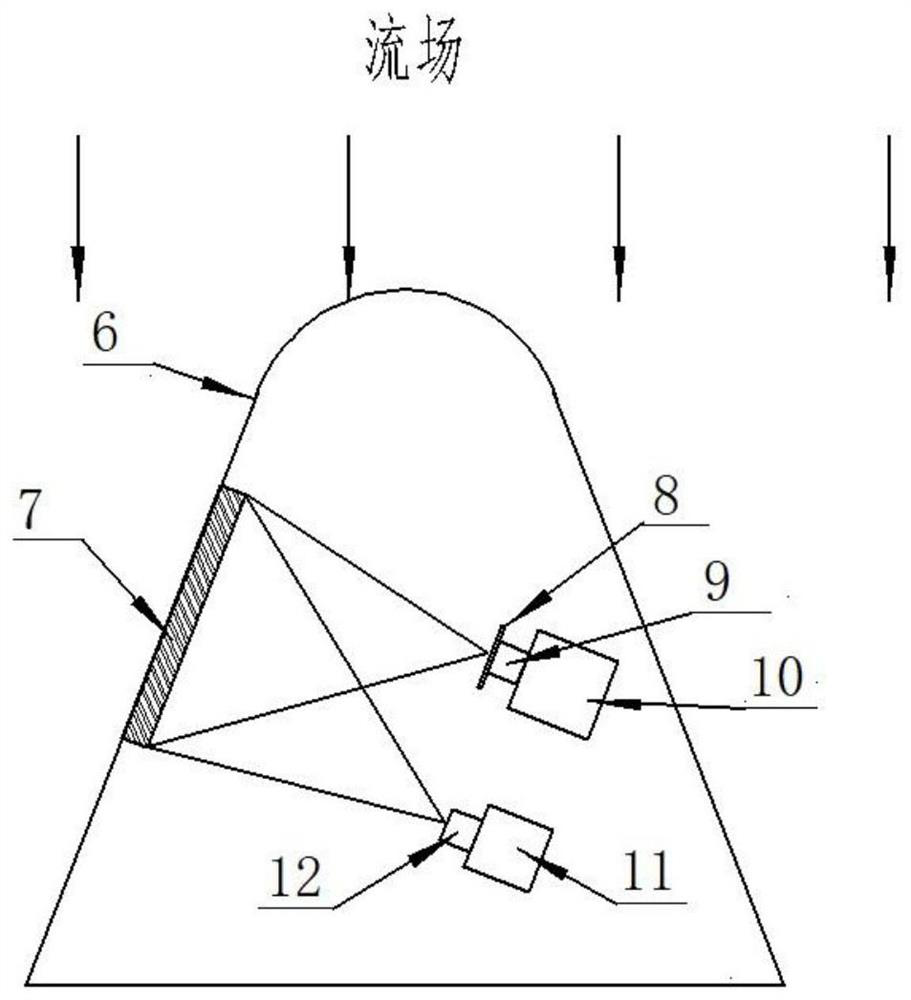

[0076] Such as figure 2 As shown, an aerodynamic thermal full-field measurement system based on an embedded temperature-sensitive paint is characterized in that the measurement system includes a measurement sensitive unit 7, an excitation light source 11, a beam expander 12, an optical filter 8, and an imaging lens 9 , camera 10,

[0077] The measurement sensitive unit 7 is set as a built-in structure, the measurement sensitive unit 7 is installed flush with the surface of the model 6, the excitation light source 11 is connected with the beam expander 12, and the imaging lens 9 and the optical filter 8 are sequentially installed At the front end of the camera 10, the illuminated area of the beam expander 12 coincides with the imaging area of the imaging lens 9 and covers the entire measurement sensitive unit 7. The excitation light source 11 illuminates the measurement sensitive unit 7 to generate radiant light, which is collected by the imaging lens 9 and then collected ...

Embodiment 2

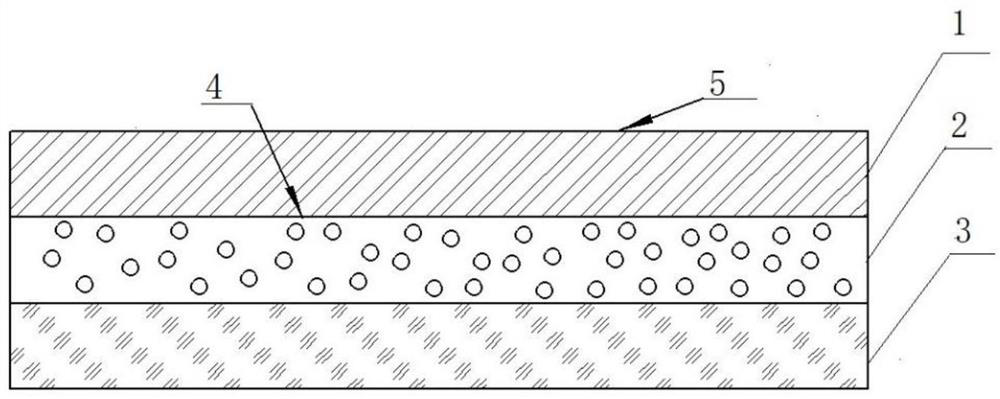

[0080] On the basis of embodiment 1, different from the embodiment, another embodiment of the present invention, such as figure 1 As shown, the measurement sensitive unit 7 is set as a structure composed of a calorimetric layer 1 , a temperature-sensitive paint layer 2 and a glass substrate 3 , and inverts the heat flow of the outer wall through the inner wall temperature of the calorimetric layer 1 .

[0081] The calorimetric layer 1 is a heat-absorbing element, which is made of metal and has the same shape as the experimental model 6. Its outer wall 5 is in contact with the hypersonic flow field; The heat flux is related to the test time.

[0082] The measurement sensitive unit 7 bears the pneumatic pressure through the glass substrate 3. When the thickness of the calorimetric layer 1 is thick enough to bear the pneumatic pressure, the glass substrate 3 can be omitted.

[0083] The temperature-sensitive paint layer 2 is sprayed on the inner wall surface 4 of the calorimetri...

Embodiment 3

[0088] On the basis of embodiment 2, another embodiment of the present invention, such as figure 1 As shown, the measurement sensitive unit 7 manufacturing method includes the following steps:

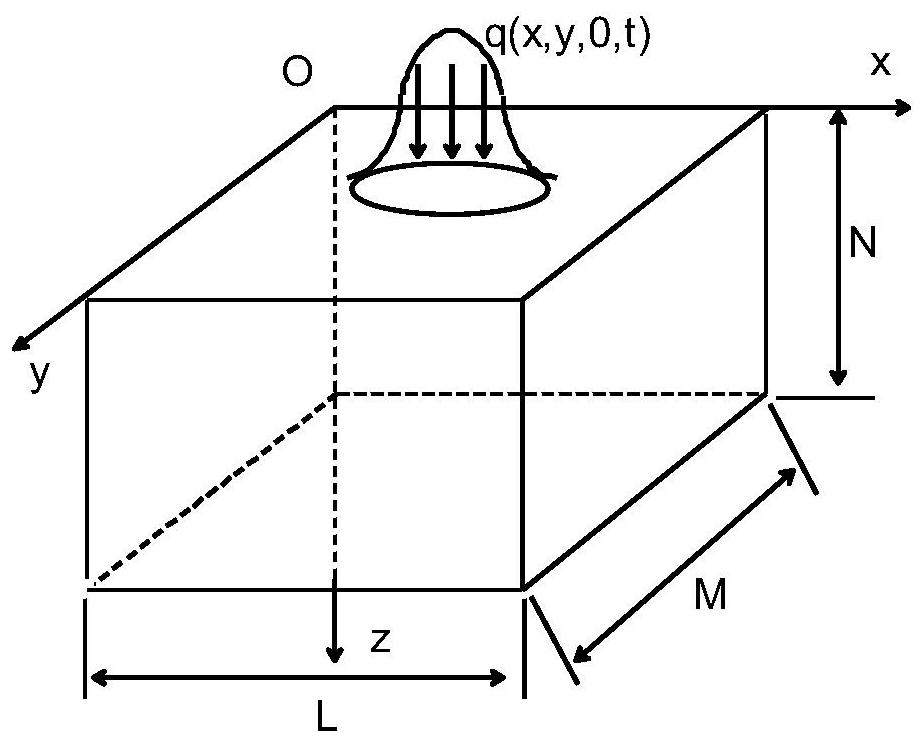

[0089] (1) Determine the shape of the measurement sensitive unit 7:

[0090] The shape of the measurement sensitive unit 7 is consistent with the shape of the experimental model 6 in the tested area, and the measurement sensitive unit 7 is installed flush with the surface of the model 6 to ensure that the aerodynamic and thermal environment of the experimental model 6 is not changed.

[0091] (2) Determine the thickness and material of calorimetric layer 1:

[0092] Analyze the aerodynamic thermal environment to be measured, estimate the peak heat flux density, preliminarily give the material (commonly used metal materials, such as copper, aluminum, stainless steel, etc.) and thickness of the calorimetric layer 1, and determine the calorimetric layer 1 by solving the unsteady heat con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com