Polishing liquid capable of removing silicon dioxide particles

A technology of silicon dioxide and polishing fluid, applied in the field of polishing, can solve the problems of difficult removal, reduction of effective use area of substrate, failure of substrate cleaning, etc., and achieve the effect of not reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The volume ratio of component one in the polishing liquid is 10%; the volume ratio of component two is 90%.

[0022] The volume ratios of isopropanol, dipropylene glycol methyl ether, propylene glycol methyl ether, ethanol, nonionic surfactant and pH regulator in component one are 2%, 5%, 5%, 20%, 63% and 5% respectively . After mixing, the pH of component one was 13.5.

[0023] Use the P810 polishing machine, the speed of the polishing disc is: the upper disc is 15-35rmp; the lower disc is 15-35rmp; the polishing cloth is a soft black polyurethane damping polishing cloth; the polishing time: 30-150 seconds. After the polishing is completed, it is transferred to the cleaning process and processed normally.

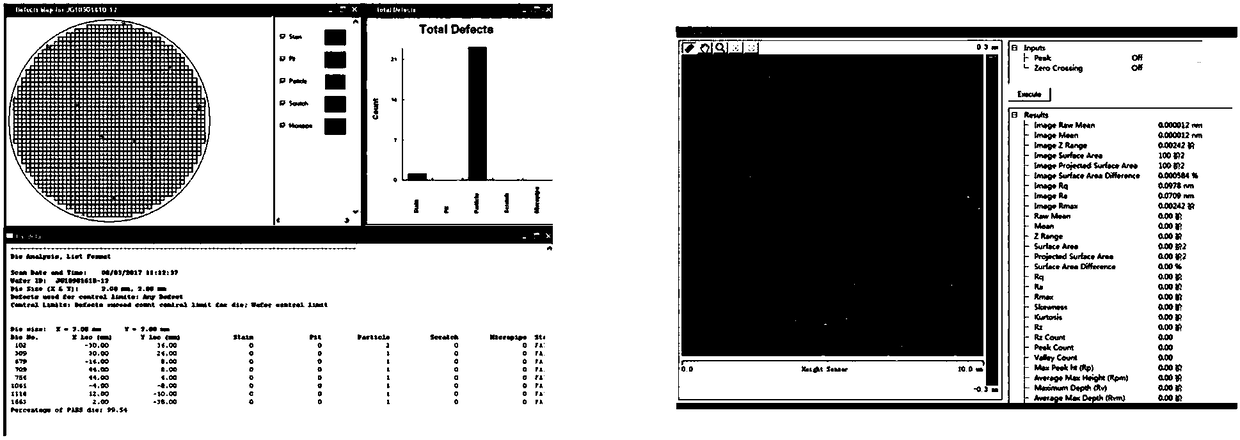

[0024] After cleaning, Candela and AFM test results are as follows figure 1 Shown: the effective area of the substrate is 99.19%, and Ra is 0.0877nm.

Embodiment 2

[0026] The volume ratio of component one in the polishing liquid is 20%; component two is 80%.

[0027] The volume ratios of isopropanol, dipropylene glycol methyl ether, propylene glycol methyl ether, ethanol, nonionic surfactant and pH regulator in component one are 5%, 8%, 4%, 15%, 59% and 3% respectively . After mixing, the pH of ingredient one was 14.

[0028] Use the P810 polishing machine, the speed of the polishing disc is: the upper disc is 15-35rmp; the lower disc is 15-35rmp; the polishing cloth is a soft black polyurethane damping polishing cloth; the polishing time: 30-150 seconds. After the polishing is completed, it is transferred to the cleaning process and processed normally.

[0029] After cleaning, Candela and AFM test results are as follows figure 2 Shown: the effective area of the substrate is 99.54%, and Ra is 0.0709nm.

Embodiment 3

[0031] The volume ratio of component one in the polishing liquid is 20%; component two is 80%.

[0032] The volume ratios of isopropanol, dipropylene glycol methyl ether, propylene glycol methyl ether, ethanol, nonionic surfactant and pH regulator in component one are 3%, 7%, 7%, 18%, 61% and 4% respectively . After mixing, the pH of component one was 13.6.

[0033] Use the P810 polishing machine, the speed of the polishing disc is: the upper disc is 15-35rmp; the lower disc is 15-35rmp; the polishing cloth is a soft black polyurethane damping polishing cloth; the polishing time: 30-150 seconds. After the polishing is completed, it is transferred to the cleaning process and processed normally.

[0034] After cleaning, Candela and AFM test results show that the effective area of the substrate is 99.28%, and Ra is 0.0651nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com