Chemical analysis test method for rapid determination of high content manganese in aluminum alloy

A rapid determination and testing method technology, applied in the field of chemical analysis, can solve the problems of difficult maintenance, low detection range, cumbersome analysis steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

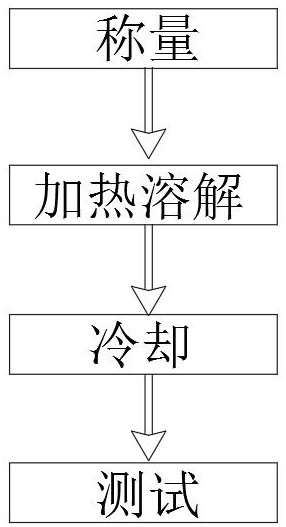

[0022] see figure 1 , the present invention provides a kind of chemical analysis test method to the rapid determination of high-content manganese in aluminum alloy, comprising the following steps:

[0023] Step 1: Weighing, weigh 0.2000-0.2500gGBW(E)020060 standard sample and a certain alloy sample to be inspected in a 300mL conical flask, wet with a small amount of water, add 15mL phosphoric acid, 5mL nitric acid in a high-temperature electric furnace (360°C) Decompose the sample on the top until it is completely removed, and take it down when there are no large bubbles and white smoke on the liquid surface;

[0024] Step 2: Oxidation, add 1mL of perchloric acid and continue to heat and dissolve on the electric furnace, and shake fully, heat until the liquid surface is completely calm, there are no small bubbles in the solution when shaking, so that the Mn 2+ Oxidized to Mn 3+ ;

[0025] Step 3: Remove and cool to 60-70°C, add 5mL of 1:1 sulfuric acid, dilute to 70-80 mL w...

Embodiment 2

[0032] see figure 1 , the present invention provides a kind of chemical analysis test method to the rapid determination of high-content manganese in aluminum alloy, comprising the following steps:

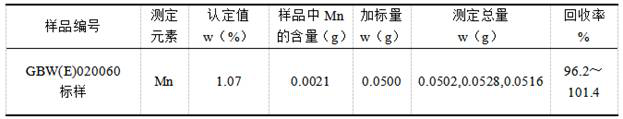

[0033] Step 1: Weighing, weigh 0.2000-0.2500gGBW(E)020060 standard sample in a 300mL conical flask, moisten it with a small amount of water, add 0.0500g high-purity manganese powder, add 15mL phosphoric acid, 5mL nitric acid in a high-temperature electric furnace (360°C ) to decompose the sample until it is completely removed, and take it down when there are no large bubbles and white smoke on the liquid surface;

[0034] Step 2: Oxidation, add 1mL of perchloric acid and continue to heat and dissolve on the electric furnace, and shake fully, heat until the liquid surface is completely calm, there are no small bubbles in the solution when shaking, so that the Mn 2+ Oxidized to Mn 3+ ;

[0035] Step 3: Remove and cool to 60-70°C, add 5mL of 1:1 sulfuric acid, dilute to 70-80 mL wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com