Alcohol-resistant caramel color as well as preparation method and application thereof

A technology of caramel color and alcohol resistance, which is applied in the fields of application, confectionery, and confectionery industry. It can solve the problems of product turbidity and loss of light, uneven quality, and poor stability of alcohol resistance, so as to improve the color and stability of alcohol resistance. , reduce moisture content, improve the effect of alcohol resistance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

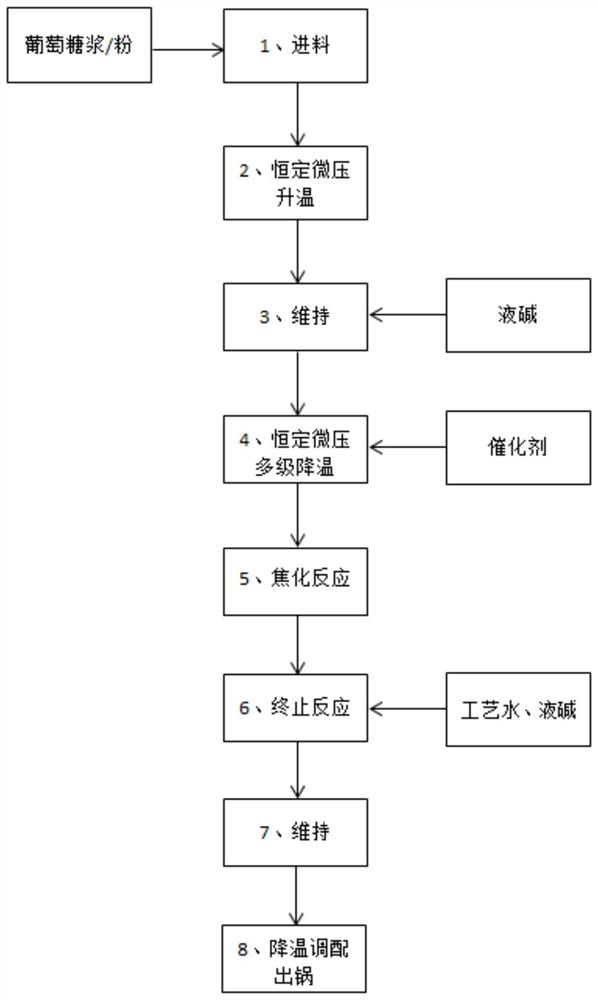

Image

Examples

Embodiment 1

[0068] The glucose syrup is pumped into the reactor through a high-pressure pump, the positive pressure in the reactor in the reaction system is controlled to be 0.01-0.05 MPa, and the dry matter content of the glucose syrup is ≥75%.

[0069] The material is heated rapidly, from room temperature to 160°C.

[0070] Then, an alkaline solution (20 wt % sodium hydroxide aqueous solution) was added into the reaction kettle to adjust the pH value of the materials in the kettle to 3.0.

[0071] After the addition of the alkali solution is completed, the temperature of the material in the kettle is maintained at 160° C., and the reaction is carried out for 5 to 15 minutes.

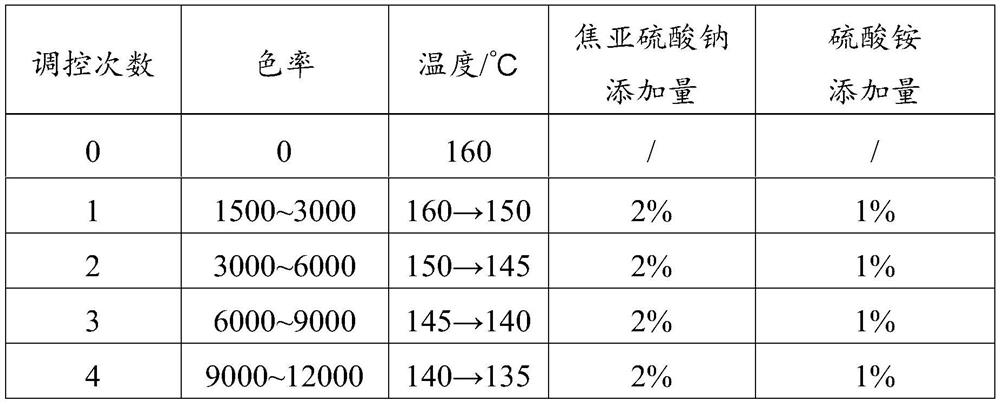

[0072] Then, according to the color rate value of the material, the addition method of the auxiliary material is regulated, and the specific regulation method is as follows:

[0073] Table 1

[0074]

[0075] After the addition of auxiliary materials, the temperature of the materials is kept at 135°C, and the...

Embodiment 2

[0083] The glucose syrup is pumped into the reactor through a high-pressure pump, the positive pressure in the reactor in the reaction system is controlled to be 0.01-0.05 MPa, and the dry matter content of the glucose syrup is ≥75%.

[0084] The material is heated rapidly, from room temperature to 150°C.

[0085] Then add alkali solution (20wt% sodium hydroxide aqueous solution) to the reaction kettle to adjust the pH value of the material in the kettle to 9.0.

[0086] After adding the alkali solution, keep the material temperature in the kettle at 150°C and react for 5-15 minutes.

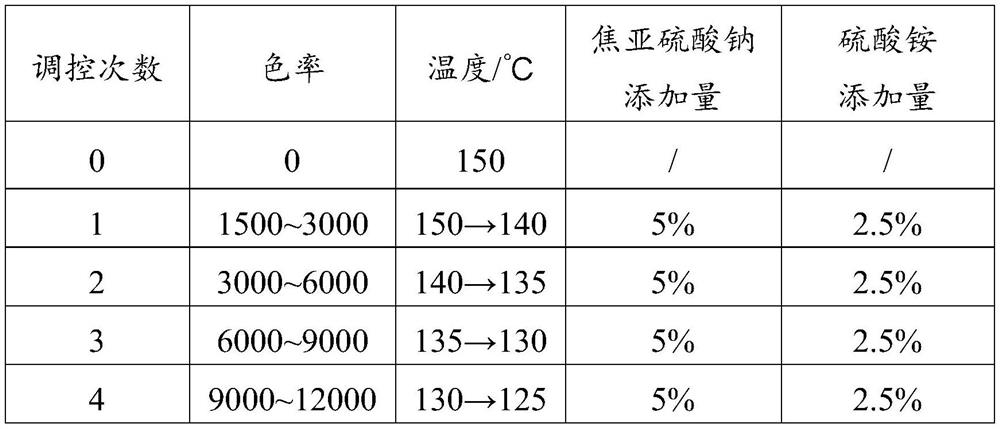

[0087] Then, according to the color rate value of the material, the addition method of the auxiliary material is regulated, and the specific regulation method is as follows:

[0088] table 3

[0089]

[0090] After the addition of auxiliary materials, the temperature of the materials is kept at 125°C, and the coking reaction is carried out for 3 hours. During this period, the positive press...

Embodiment 3

[0095] The glucose syrup is pumped into the reactor through a high-pressure pump, the positive pressure in the reactor in the reaction system is controlled to be 0.01-0.05 MPa, and the dry matter content of the glucose syrup is ≥75%.

[0096] The material was heated rapidly, from room temperature to 155°C.

[0097] Then, an alkali solution (20 wt % sodium hydroxide aqueous solution) was added into the reaction kettle to adjust the pH value of the materials in the kettle to 4.0.

[0098] After adding the alkali solution, keep the material temperature in the kettle at 155°C and react for 5-15 minutes.

[0099] Then, according to the color rate value of the material, the addition method of the auxiliary material is regulated, and the specific regulation method is as follows:

[0100] Table 4

[0101]

[0102] After the auxiliary materials are added, the material temperature is kept at 130°C, and the coking reaction is carried out for 3 hours. During this period, the positive...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap