Novel straight gear shaping device for gear machining

A technology for gears and tooth planing, applied in the field of new straight tooth planing devices for gear processing, can solve problems such as damaged gears, iron scraps scratching the surface of gears, and iron scraps not being completely filtered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

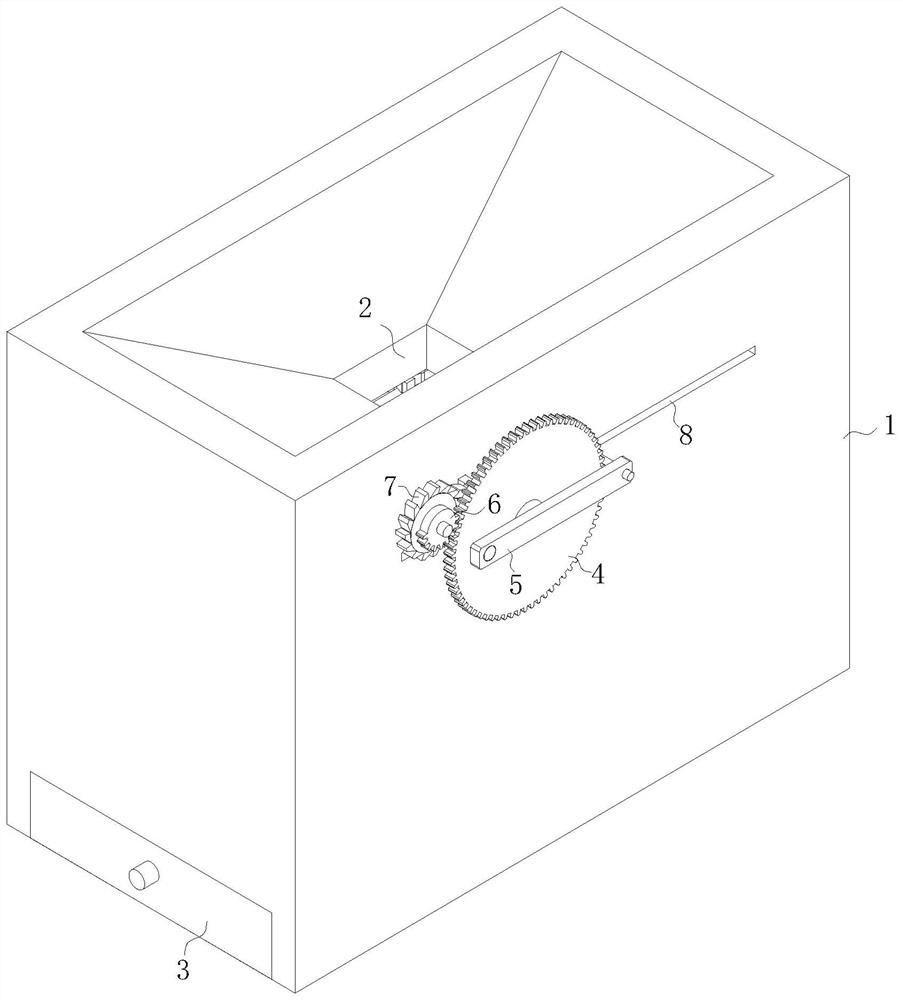

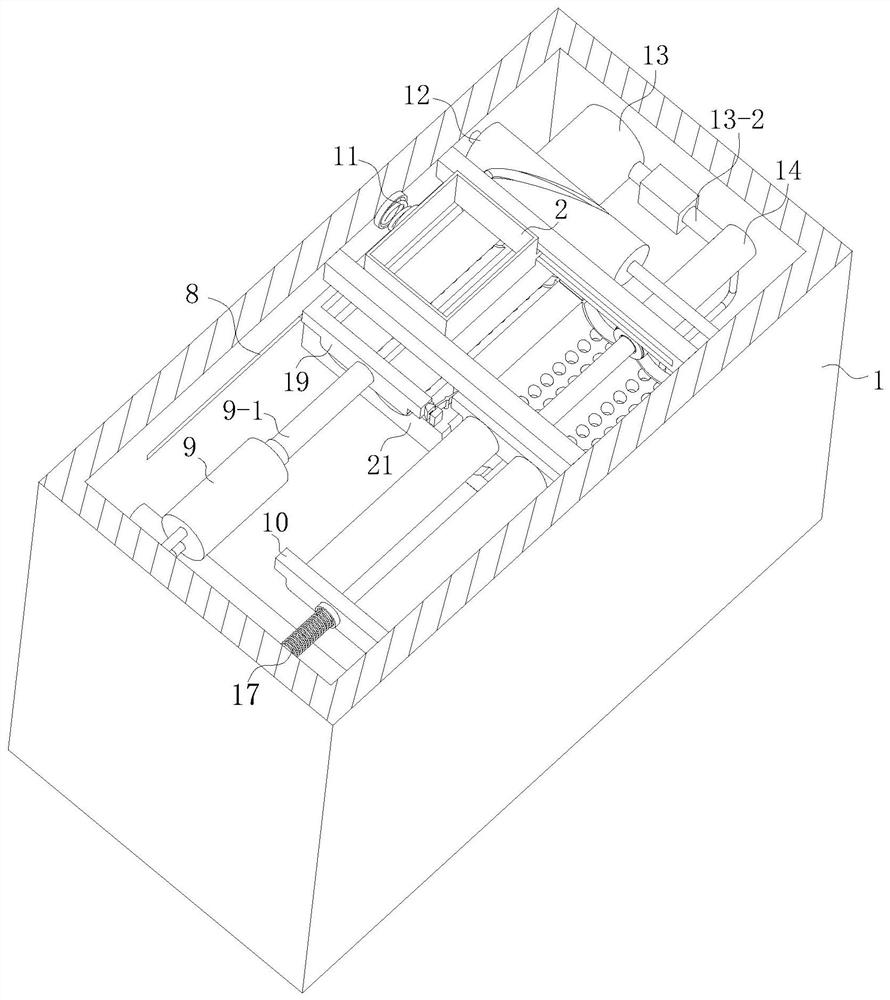

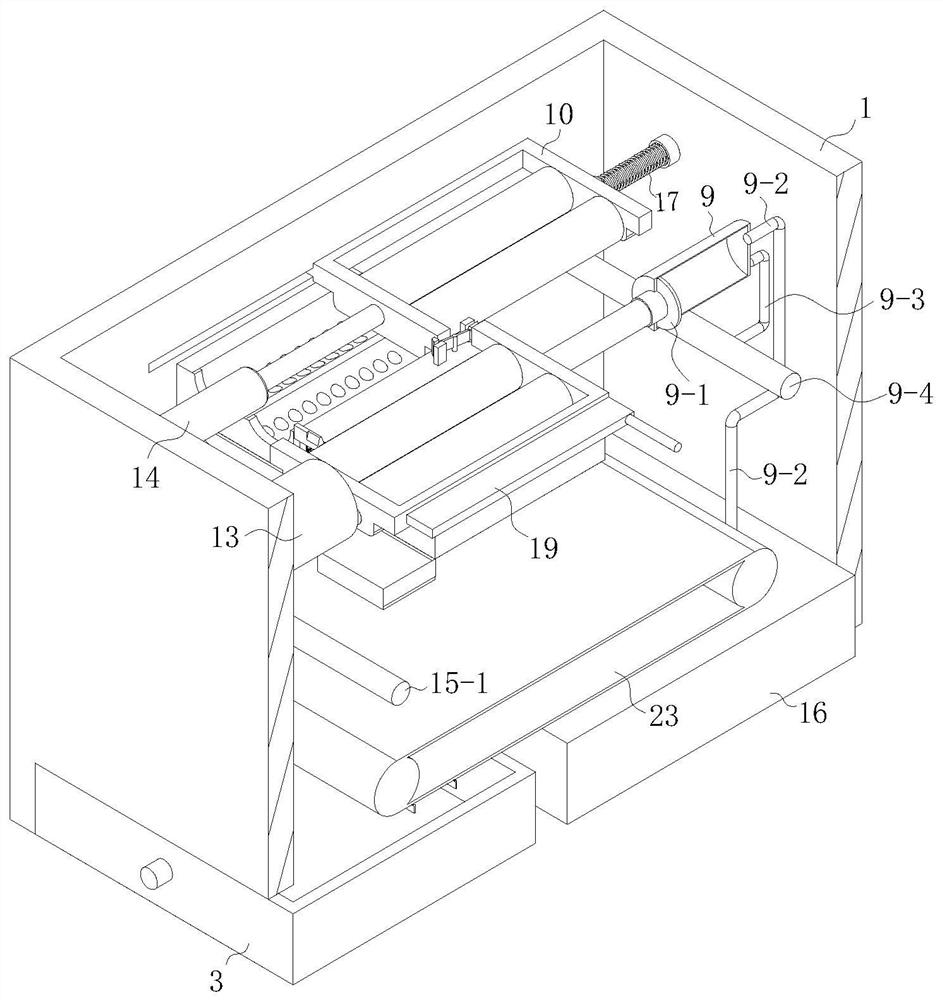

[0031] see Figure 1-12 , the present invention provides a technical solution: a new type of straight gear planer for gear processing, including a casing 1, the top of the casing 1 is provided with a blanking port 2, and the blanking port 2 can be placed on the casing 1 The inner wall slides in the left and right directions, and the left electromagnet assembly 10 is slidably connected to the left inner wall of the casing 1. The right side wall of the casing 1 is provided with a first chute 8, and the first chute 8 A right electromagnet assembly 19 located inside the casing 1 is slidably connected to the inside. A first driving mechanism is arranged inside the casing 1, and a second drive mechanism is arranged between the left electromagnet assembly 10 and the right electromagnet assembly 19. Drive mechanism;

[0032] The first drive mechanism includes a first gear 4, a half gear 6 and a first spring 11, the first gear 4 is rotatably connected to the outer wall of the casing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com