Robot force-controlled end effector and control method thereof

A technology of end effector and control method, which is applied in the direction of automatic grinding control device, workpiece feed movement control, manufacturing tools, etc., can solve the problems of poor control performance, slow response speed, large mechanical vibration, etc., and achieve simple structure Compactness, slow response, noise and vibration reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

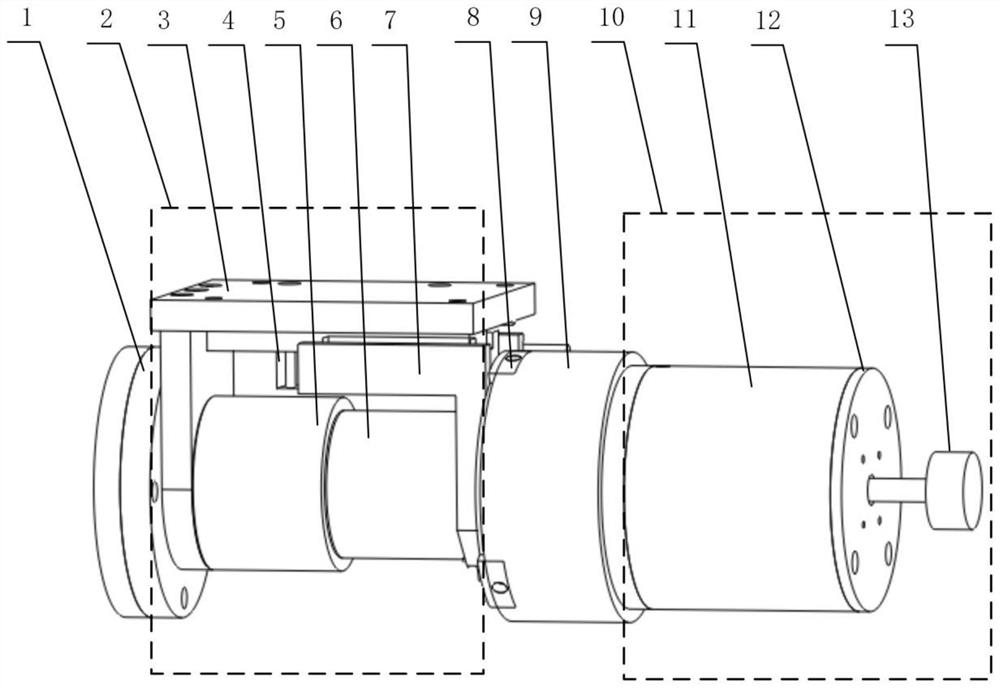

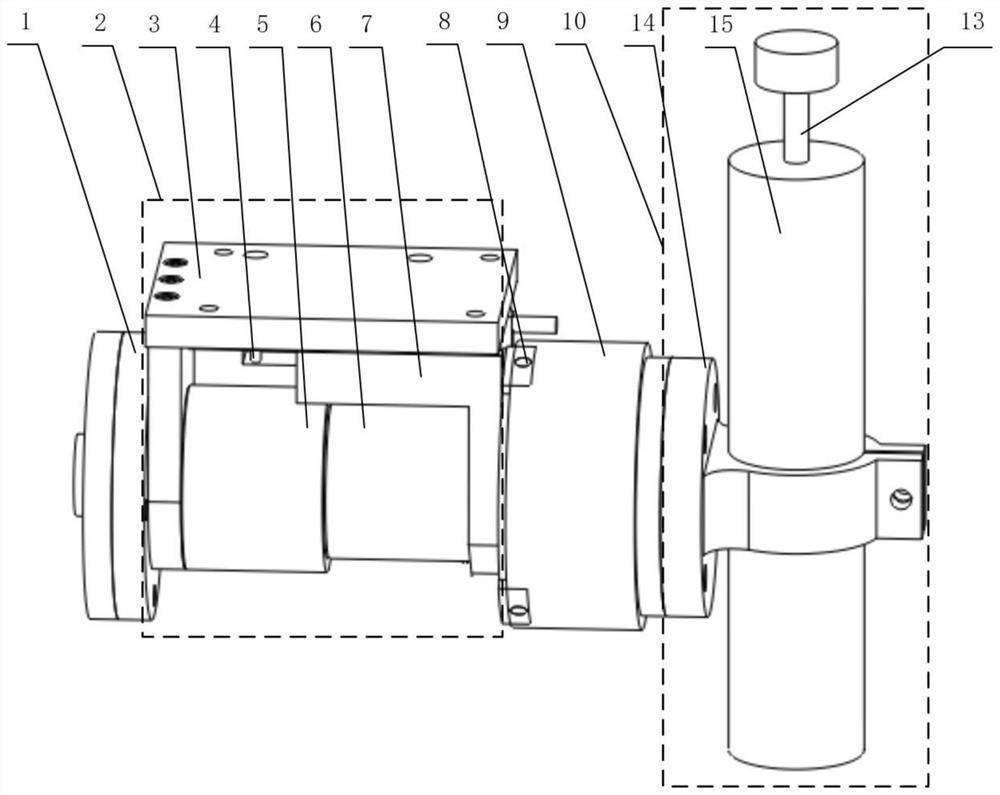

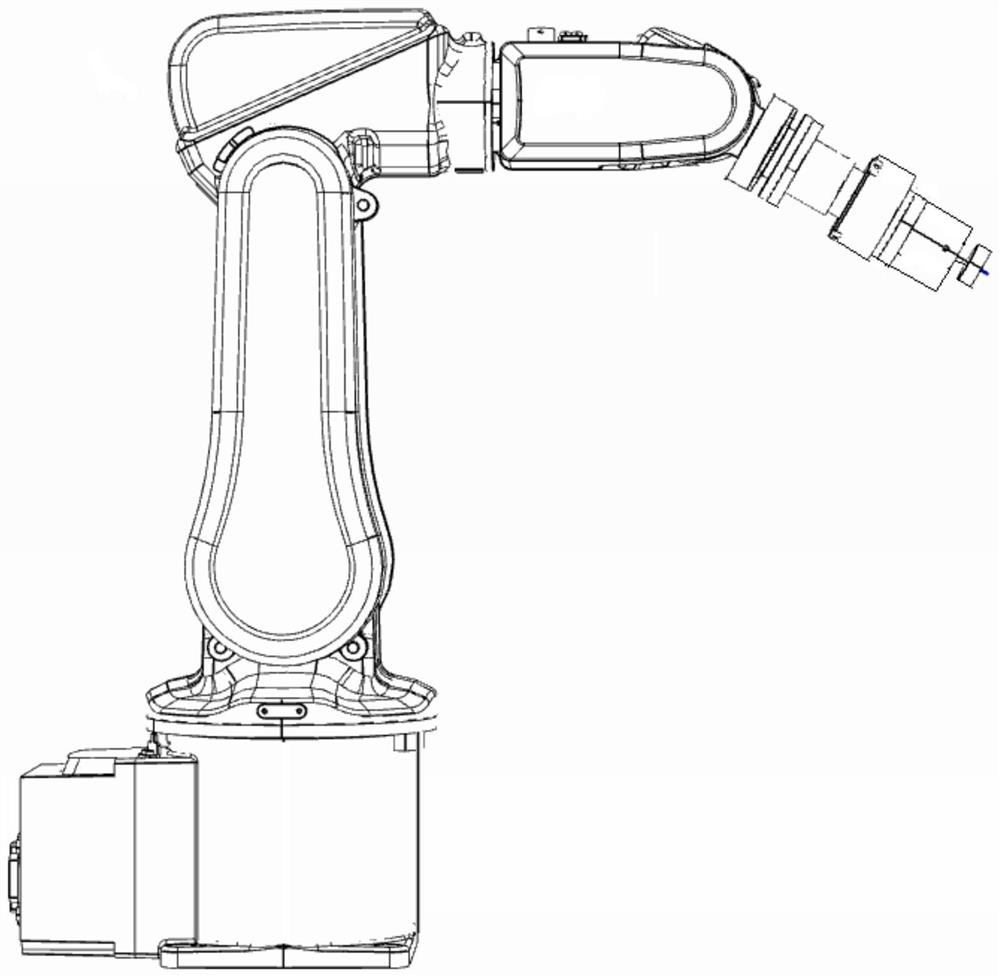

[0038] A force-controlled end effector for a robot, comprising: a connecting flange 1, a voice coil motor module 2, a force sensor 9, a controller, and a grinding module 10, and the voice coil motor module 2 includes: a voice coil motor, a bracket 3, and a linear guide rail 7 and the displacement sensor 4, the linear guide 7 and the stator of the voice coil motor are fixed on the bracket 3, the mover of the voice coil motor is fixed to the slider on the linear guide, and the linear guide is used as a guide connecting the mover and stator of the voice coil motor The device is used to connect the flange 1 and the bracket 3, and is used to fix the voice coil motor module 2 and the robot, so as to realize the connection between the pose control of the robot and the grinding and polishing force control of the force-controlled end effector of the robot; the force sensor One end of 9 is fixedly installed with the mover of the voice coil motor, and the other end is installed with a gri...

Embodiment 2

[0041] On the basis of Embodiment 1, the force sensor 9 is fixed to the mover of the voice coil motor through a mounting flange 8 . The electric spindle is parallel to the sliding direction of the slide block on the linear guide rail 7 (axial grinding) or vertical (radial grinding).

Embodiment 3

[0043] On the basis of Embodiment 2, when the electric spindle is parallel to the sliding direction of the slider on the linear guide rail 7, the grinding module 10 further includes: a sleeve 11, the sleeve 11 is installed on the force sensor 9, and one end of the electric spindle is positioned on the sleeve The other end of the cylinder 11 protrudes from the sleeve 11 and is fixed with the grinding head 13 . The electric spindle is fixedly installed with the sleeve through the fixing flange 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com