Resin water filtering device and flushing method

A resin filtration and water filtration technology, applied in chemical instruments and methods, filtration treatment, water/sewage treatment, etc., can solve problems such as cumbersome operation, leakage, blocked valves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

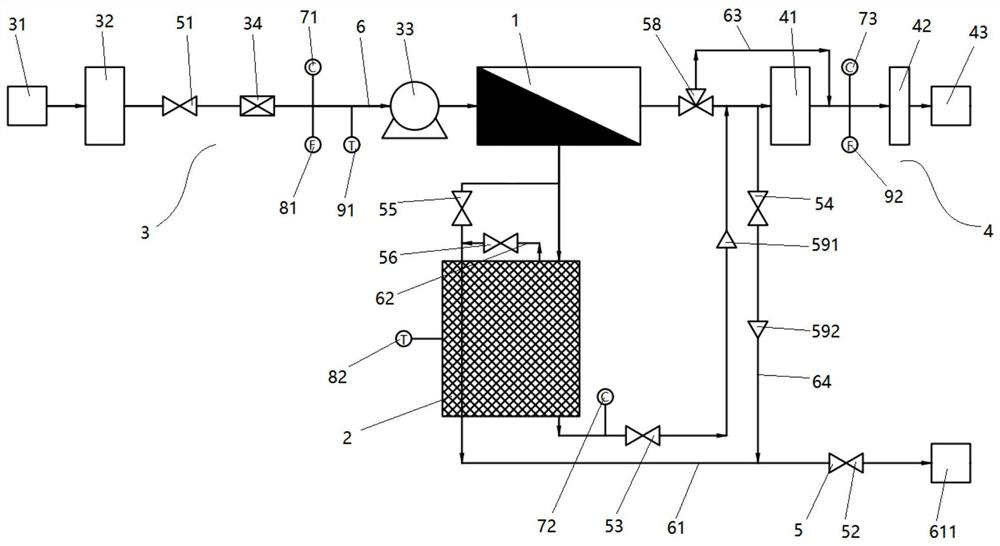

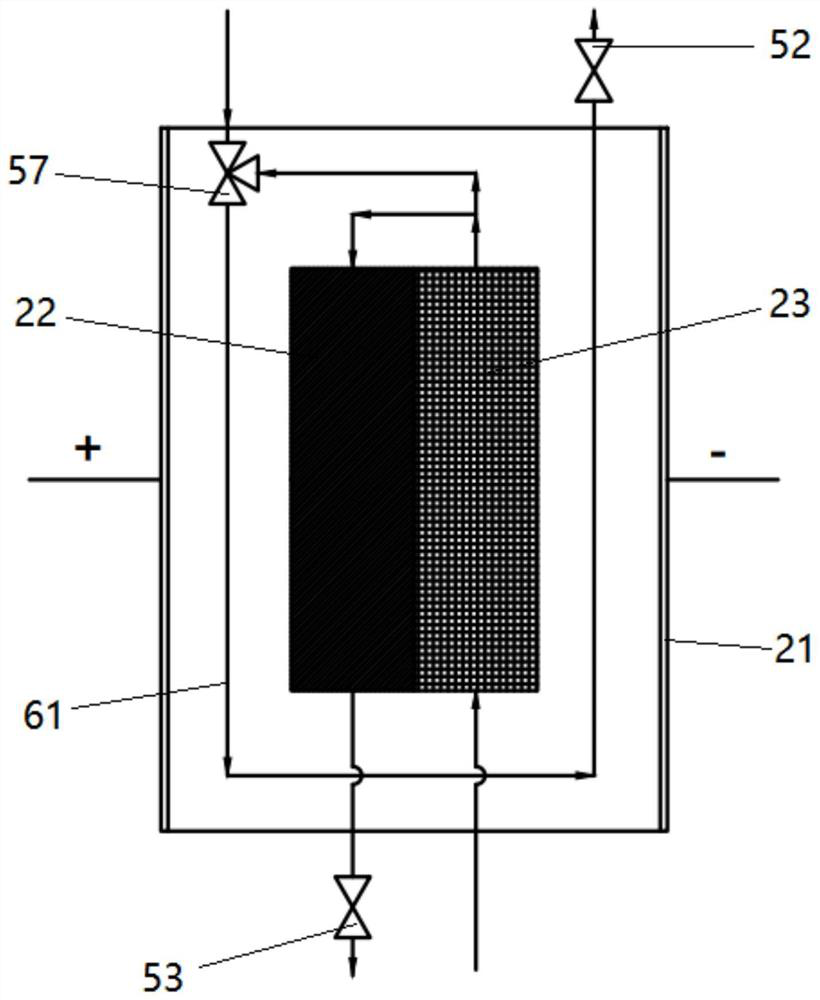

[0061] A resin drainage apparatus, comprising a pre-processing means 6 in turn connected by a pipe 3, a reverse osmosis means, and the resin was filtered mechanism 2 4 post-processing means; a plurality of attached pipe 6 for controlling the on-off and / or the pipe 6 size of the flow valve 5; the resin was filtered mechanism 2 comprises a housing 21, provided in the cartridge housing in the anion resin and cation resin filter 21 22 23; 22 communicating with the female resin filter cartridge 23 of the male resin the anion resin filter element 22 and the male resin filter 23 are in communication with the conduit 6.

[0062] By the above-described embodiment, the present invention is to obtain at least the following technical effect: by controlling the valves 5, so that water flows from the pre-processing means 3, sequentially through the reverse osmosis means 1, filter means 2 the resin was treated to obtain purified water bodies 4. Purified water to achieve water softening effect ...

Embodiment 2

[0086] On the basis of the embodiment 1, the present invention also provides a method of flushing, the resin in the water treatment apparatus of the above-described embodiment, comprising the steps of:

[0087] S1: RO flushing mechanism 1;

[0088]The first solenoid valve 51, the second solenoid valve 52, the fifth solenoid valve 55, the second three-way valve 58 are turned off; the third solenoid valve 53, the fourth solenoid valve 54, the sixth soot electromagnetic valve 56 ;

[0089] The diaphragm pump 33 is activated, and the tap water is sequentially flowed through the PP / Scratchive activated carbon filter assembly 32, the first solenoid valve 51, the pressure reducing valve 34, and the diaphragm pump 33 flow into the reverse osmosis mechanism 1.

[0090] The flow of water filtered through reverse osmosis mechanism 1 is divided into two parts: concentrated water concentrated after filtration of reverse osmosis mechanism 1 is sequentially flowed through the regenerated water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com