Separating device and water treatment equipment thereof

A technology of electrodeionization and ion exchange membrane, applied in the field of water treatment, which can solve the problems of complex design of electrochemical deionization structure, decline of desalination performance, water flow blockage, etc., to avoid gas and scaling, high water production rate, and water Less waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A bipolar membrane electrodeionization device, comprising at least one pair of electrode groups, the bipolar membrane electrodeionization device includes at least one pair of characteristic electrode groups and more than one bipolar electrode group located between the two electrodes constituting the characteristic electrode group Pole membrane, the characteristic electrode group includes at least one porous electrode. Each bipolar membrane is composed of a cation exchange membrane and an anion exchange membrane that are bonded together. There is no flow between the cation exchange membrane and the anion exchange membrane that constitute the same bipolar membrane. road.

[0039] A pair of characteristic electrode groups can be composed of two porous electrodes, and a pair of characteristic electrode groups can also be composed of a porous electrode and a common electrode. Common electrodes such as metal electrodes, titanium electrodes with ruthenium-yttrium coating, ruth...

Embodiment 2

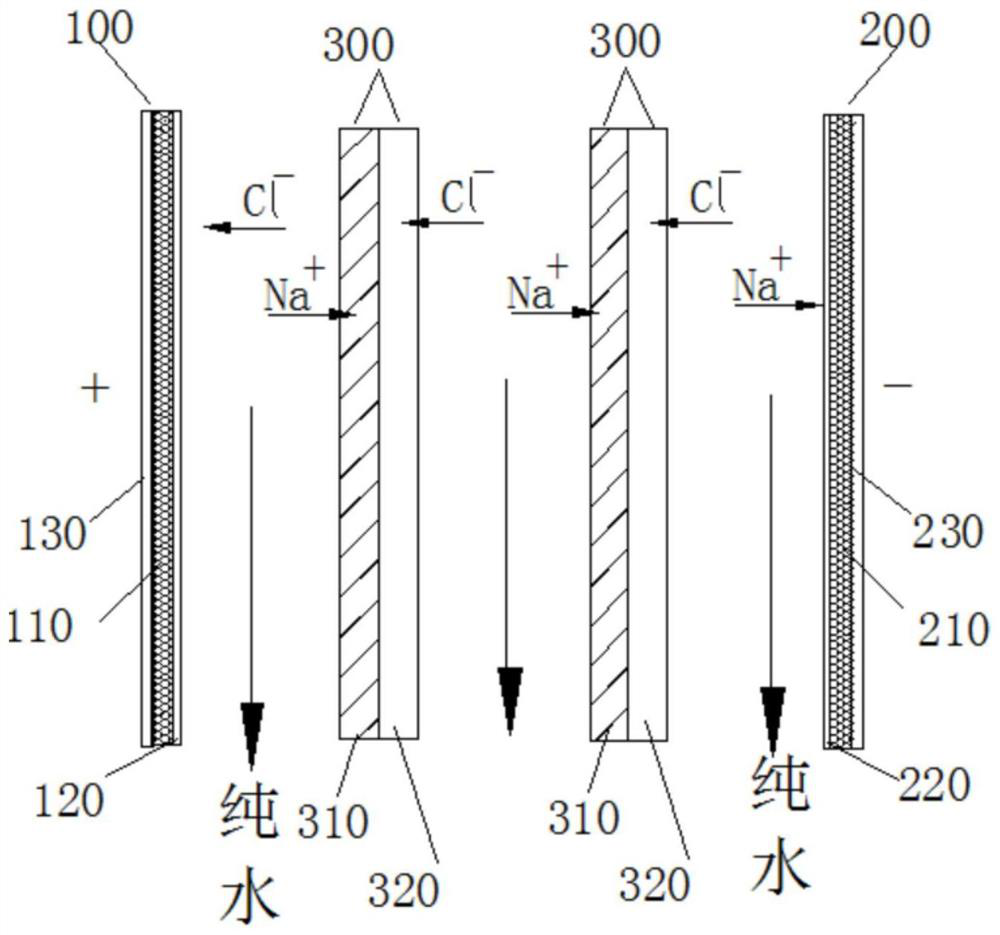

[0065] A bipolar membrane electrodeionization device, such as image 3 , Figure 4 As shown, the other features are the same as those in Embodiment 1, except that in this embodiment, the porous electrode 100 is formed by stacking the current collector 130, the porous material 110, and the anion exchange membrane 120 sequentially, and the porous electrode 100 is a negative membrane electrode. The porous electrode 200 is formed by sequentially stacking a current collector 230 , a porous material 210 , and a cation exchange membrane 220 , and the porous electrode 200 is a positive membrane electrode. The porous electrode can be laminated and clamped by current collectors, porous materials, and ion-exchange membranes without the use of binders; or it can also be fixed by thermal lamination or bonded by binders.

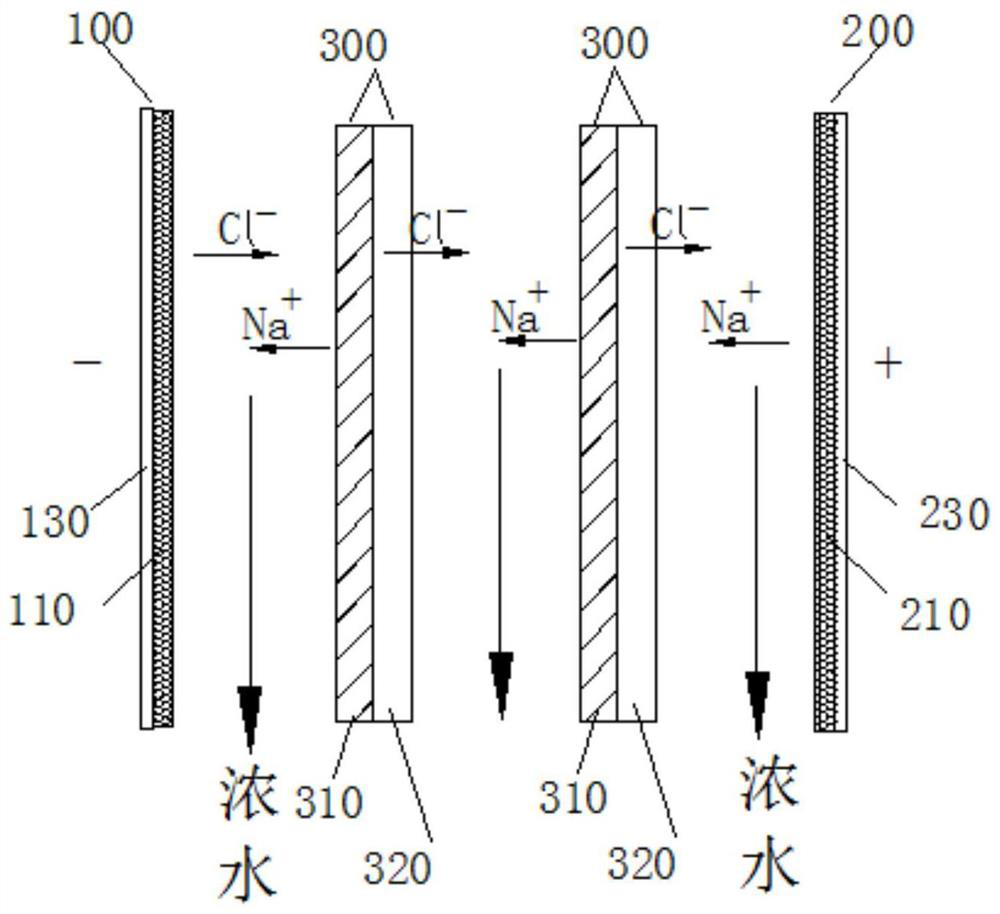

[0066] The bipolar membrane electrodeionization device of the present embodiment, its desalination process is such, as image 3 As shown, during the desalination proces...

Embodiment 3

[0076] A bipolar membrane electrodeionization device, other features are the same as in Embodiment 1, the difference is that the porous electrode is not provided with a collector, and is only formed by laminating porous materials and ion exchange membranes. The electrical conductivity of the porous material in this embodiment meets the requirement of electrical conductivity, so no collector is required.

[0077] It should be noted that the specific structure of the two porous electrodes can be flexibly set according to needs, such as one porous electrode has a collector and the other porous electrode has no collector, or both porous electrodes have collectors at the same time, or both porous electrodes have collectors at the same time. The collector is not set, as long as the actual demand is met.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com