Movement control device and method for electric beam splitter of glass fiber drawing system

An electric beam splitter and control device technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low control precision of pneumatic sliding plug speed, asynchronous reciprocation of process line, unadjustable position and speed, etc. The effect of improving equipment production efficiency, ensuring speed and improving roving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

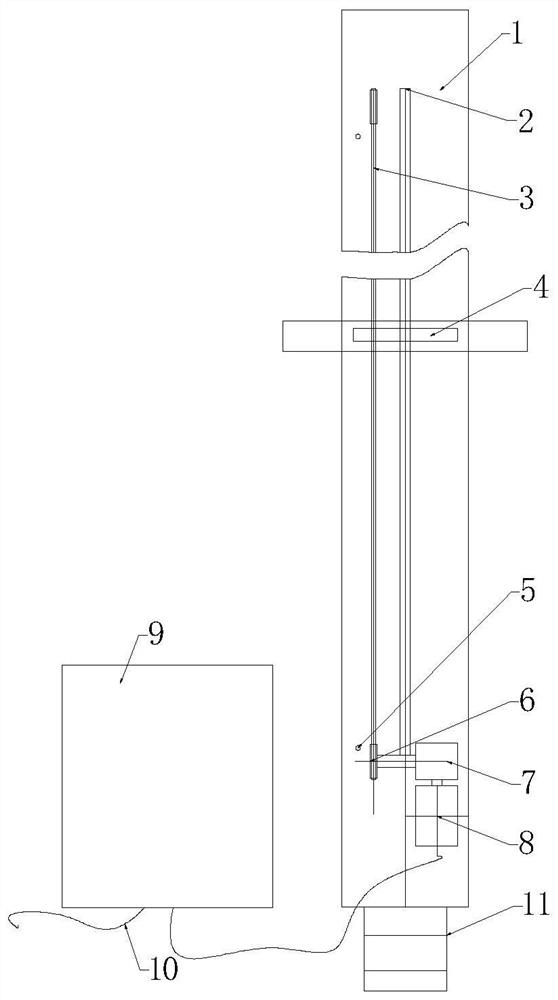

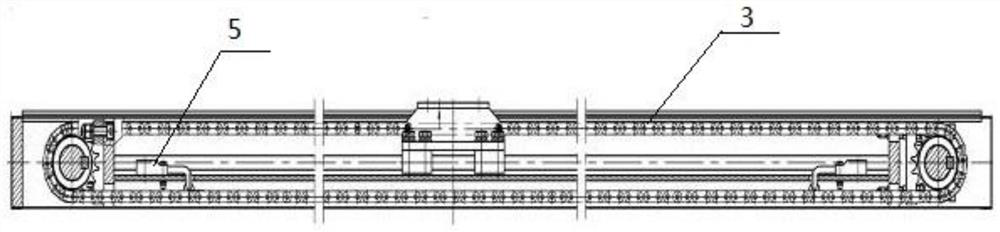

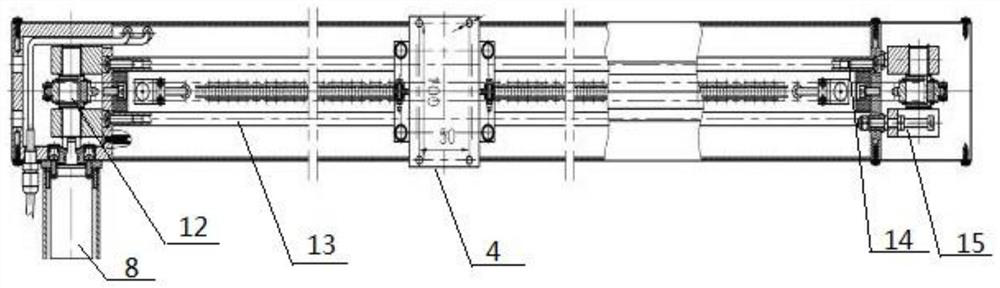

[0027] Such as Figure 1-4 As shown, a glass fiber drawing system electric beam splitter movement control device according to the present invention includes a housing 1, and the interior of the housing 1 is provided with a transmission chain 3 and a guide rod 13, and the guide rod 13 is located on the transmission chain On the left and right sides of 3, the end of the transmission chain 3 is connected with a driving sprocket 12, and the driving sprocket 12 is connected with a motor 8, and the motor 8 drives the driving sprocket 12, thereby driving the transmission chain 3 to realize transmission, and the external connection of the transmission chain 3 There is a load connecting frame 4 on which the beam splitter of the wire drawing machine is placed. The lower end of the housing 1 is provided with a position sensor 5 connected to a controller which is electrically connected to the wire drawing machine.

[0028] The motor 8 is connected with a speed reducer 7 .

[0029] The en...

Embodiment 2

[0037] A method for controlling the movement of an electric beam splitter in a glass fiber drawing system according to the present invention comprises the following steps:

[0038] Step 1: The process line is started, the beam splitter movement control device and the wire drawing machine are self-inspected and started at the same time, the beam splitter movement control device self-tests to the reversing lead wire position I through the position sensor 5, and waits for the down signal;

[0039] Step 2: After the downlink signal is obtained through the communication cable, the motor 8 runs while the push rod of the wire drawing machine of the lower equipment is retracted, and the beam splitter movement control device is driven to the reciprocating position II of the process fixed-point wire drawing, and the motor 8 stops stable operation;

[0040] Step 3: After a certain process time, follow the wire drawing machine to reciprocate and arrange the wires to be full, and the equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com