Water sample high-precision COD detection device and method

A detection device, high-precision technology, applied in the direction of measuring device, color/spectral characteristic measurement, material analysis through optical means, etc., can solve the problem of high process assembly requirements, poor design of miniaturized product structure, and influence on the outer layer of atoms Electron energy etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

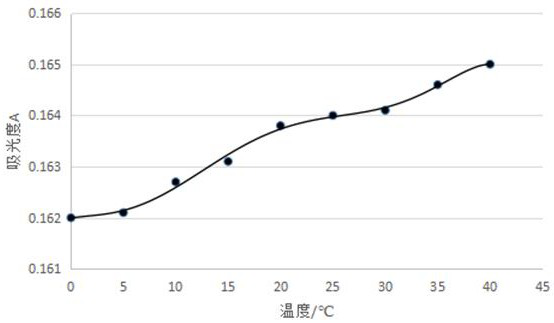

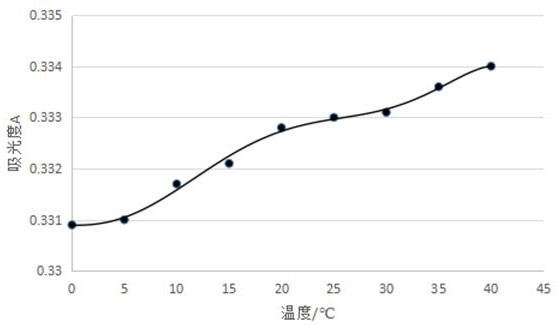

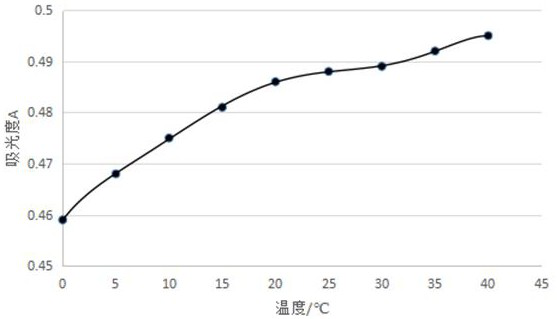

[0041] As shown in the figure, the method of the high-precision COD detection device for water samples is used to improve the detection accuracy of the micro-COD detection device. Within the temperature range required for the detection, measure the calibration data set of the COD absorbance of the calibration solution changing with temperature, and sort out the COD absorbance of the high-concentration calibration solution and the low-concentration calibration solution. The temperature compensation curve formulas of high-concentration COD water samples and low-concentration COD water samples are used to correct the measured original absorbance data when the micro-COD detection device detects water samples.

[0042] The COD detection temperature range of the miniature COD detection device is 0°C~45°C;

[0043] When measuring the data of the change of the absorbance of the calibration solution with temperature, change the temperature of the calibration solution and make it stable, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com