Turbogenerator rotor winding turn-to-turn electromagnetic pulse wave characteristic detection device and method

A technology of turbo generator and rotor winding, which is applied in the direction of electric winding test, motor generator test, measuring device, etc., and can solve the problems that cannot be done

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

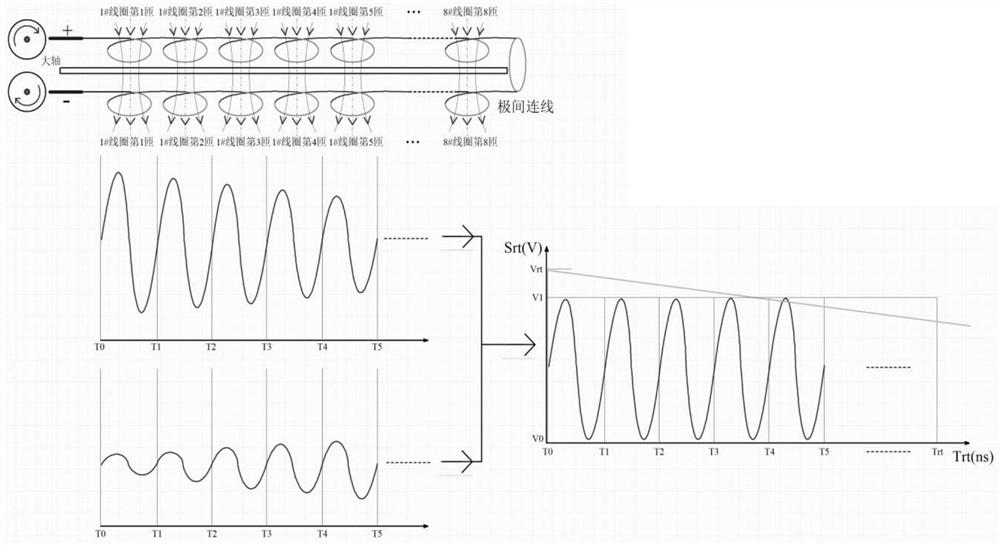

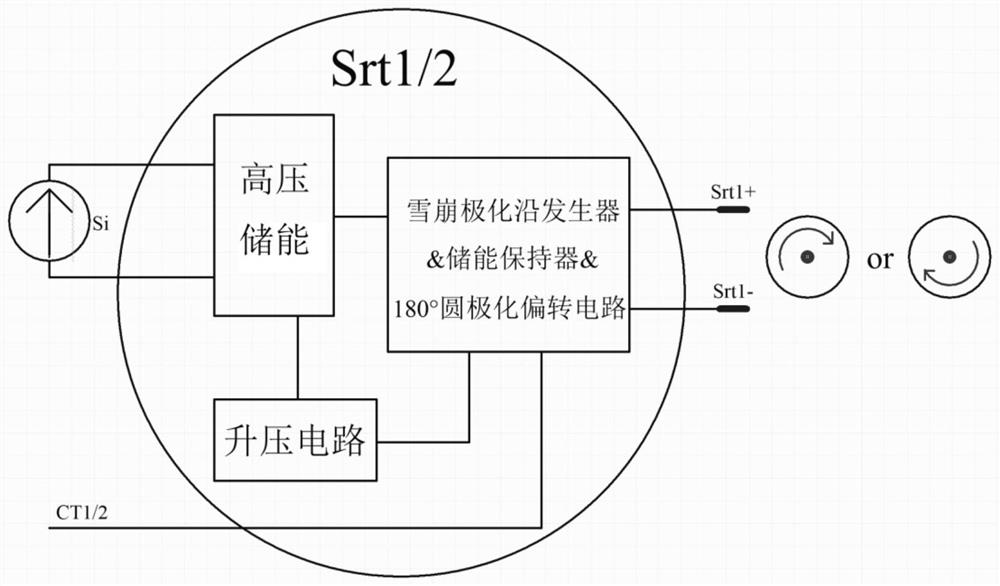

[0042] Such as Figure 1-8 As shown in the present invention, a device for detecting the inter-turn electromagnetic pulse vibration characteristics of a turbogenerator rotor winding includes a super-large-capacity internal resistance signal source, and the super-large-capacity internal resistance signal source is connected to an ultra-high-speed timing control circuit , the ultra-high-speed timing control circuit is connected to the positive and negative poles of the rotor winding through the parasitic inductive power supply through the positive and negative load guide wires, and the positive and negative poles of the rotor winding are connected to the ultra-high-speed acquisition circuit through the operational amplifier circuit.

[0043] The super-large-capacity internal resistance signal source matches the average time constant of the circular polarization characteristic of each turn of the winding, and can generate the energy width of the power circular polarization charact...

Embodiment 2

[0064] Full speed 650MW rotor 1# coil and 2# coil bridge line position is Figure 15 Middle A and a;

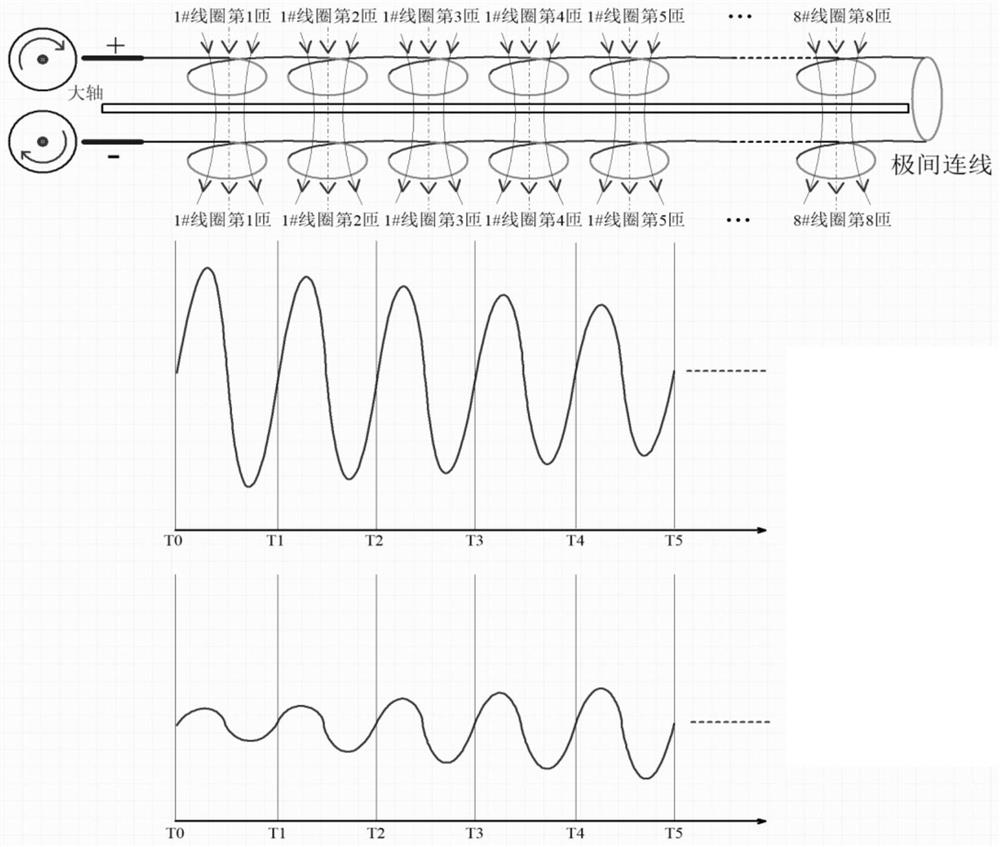

[0065] Such as Figure 9 As shown, all 62 turns of 1-8# coils of a 1# full-speed 650MW healthy rotor are clearly visible. 1# coil and 2# coil have obvious characteristics of the bridge line, and the transient wave characteristics of each turn of the rotor are healthy.

[0066] Such as Figure 10 As shown, all 62 turns of 1-8# coils of a 2# full-speed 650MW healthy rotor are clearly visible. 1# coil and 2# coil have obvious characteristics of the bridge line, and the transient wave characteristics of each turn of the rotor are healthy.

Embodiment 3

[0068] Full speed 650MW rotor 1# coil and 2# coil bridge line position is Figure 15 Middle A and a;

[0069] Such as Figure 11 As shown, all 62 turns of the 1-8# coils of a 2# full-speed 650MW sub-healthy rotor are clearly visible except that the 5th and 6th turns of the 1# coil are combined into one sine wave. 1# coil and 2# coil have no obvious characteristics of bridge line, 2# coil 1, 2 turn sine wave amplitude is too large compared with the previous cycle, it is judged that there is oil pollution, and necessary cleaning work is required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com